Sep . 06, 2024 08:22 Back to list

Precision 3D Welding Table - Enhance Your Welding Experience

Precision 3D Welding Tables Advancing Industrial Efficiency

In the rapidly evolving landscape of modern manufacturing, the importance of precision engineering cannot be overstated. One of the critical components in achieving high-quality output is the use of precision 3D welding tables. These specialized tables have transformed the way welding operations are approached, offering unparalleled accuracy and efficiency.

Precision 3D Welding Tables Advancing Industrial Efficiency

One of the standout features of these tables is their modular design. Welders can customize the layout based on their specific project needs, accommodating different sizes and shapes of materials. This versatility not only enhances productivity but also reduces material waste, as fabricators can work more efficiently without the need for constant adjustments or re-alignments.

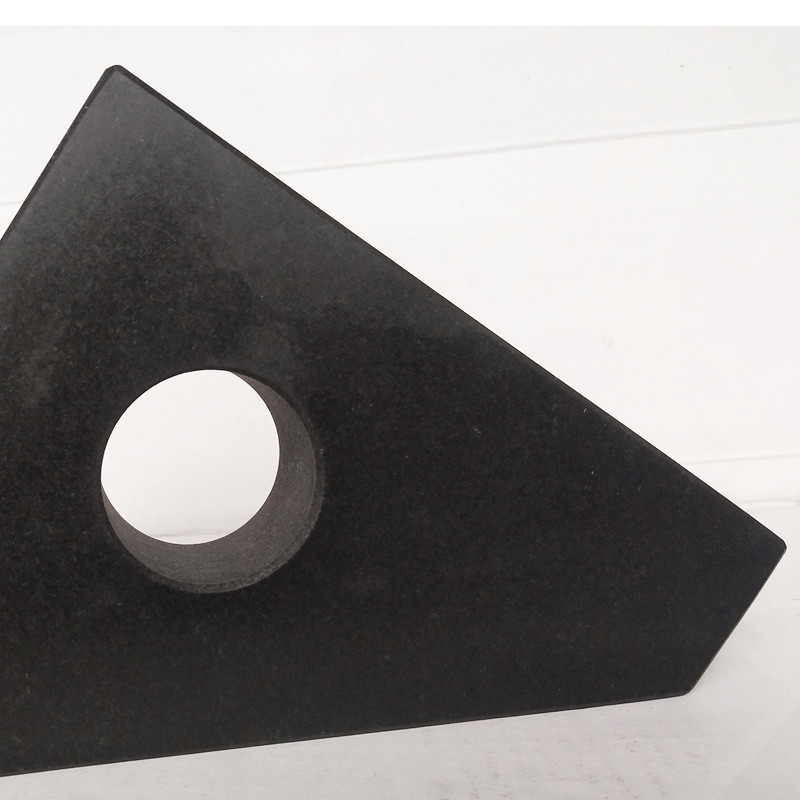

precision 3d welding table

Additionally, many precision 3D welding tables come equipped with advanced measurement systems. These integrated technologies allow operators to monitor the accuracy of their setup in real-time, significantly mitigating the risk of errors. By ensuring precise alignment before the welding process begins, manufacturers can achieve tighter tolerances and higher-quality welds, ultimately leading to improved product durability and performance.

Another notable advantage of precision 3D welding tables is their contribution to worker safety. A well-designed table reduces the risk of accidents by providing a stable work environment. Moreover, with tools and parts organized in an ergonomic fashion, operators can work more comfortably and efficiently, leading to enhanced productivity and reduced workplace injuries.

In summary, precision 3D welding tables represent a significant advancement in manufacturing technology. Their ability to provide a reliable, adjustable, and safe workspace allows welders to produce high-quality components with ease. As industries continue to demand tighter tolerances and better quality, the adoption of precision 3D welding tables is likely to grow, shaping the future of welding operations around the globe.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS