Oct . 21, 2024 06:02 Back to list

Evaluating Platform Quality and Compliance Through Comprehensive Inspections

Ensuring Safety and Quality through Platform Inspection

In today's fast-paced industrial environment, platform inspection is a critical aspect of maintaining safety and quality across various sectors such as construction, oil and gas, manufacturing, and transportation. As companies strive to comply with regulatory standards and improve operational efficiency, the importance of systematic and rigorous inspections cannot be overstated. This article delves into the significance of platform inspection, its methodologies, and the role it plays in safeguarding workers and assets.

The Importance of Platform Inspection

Platform inspections are essential for the prevention of accidents and the promotion of a safe working environment. These inspections serve multiple purposes they ensure compliance with regulatory requirements, enhance operational efficiency, and extend the lifespan of equipment. Regular inspections help identify potential hazards and mitigate risks before they escalate into serious incidents. In industries where heavy machinery and complex systems are prevalent, the consequences of neglecting inspections can be dire, leading to catastrophic failures, significant financial losses, and irreparable harm to human life.

Furthermore, a robust inspection program enhances a company's reputation. Industries that prioritize safety and compliance are viewed more favorably by clients, investors, and regulatory bodies. This positive perception can lead to increased business opportunities, competitive advantages, and ultimately, greater profitability.

Methodologies for Platform Inspection

There are several methodologies and technologies currently employed in platform inspections. These methodologies often depend on the specific industry and the equipment being inspected. Some commonly used practices include

1. Visual Inspections This is the most basic form of inspection, which involves a thorough examination of the platform and its components for visible signs of wear, corrosion, or damage. Trained inspectors often conduct these visual checks regularly, documenting their findings for further analysis.

2. Non-Destructive Testing (NDT) Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing fall under this category. NDT allows inspectors to evaluate the integrity of materials and structures without causing any damage. This is particularly useful for critical components that cannot be easily replaced.

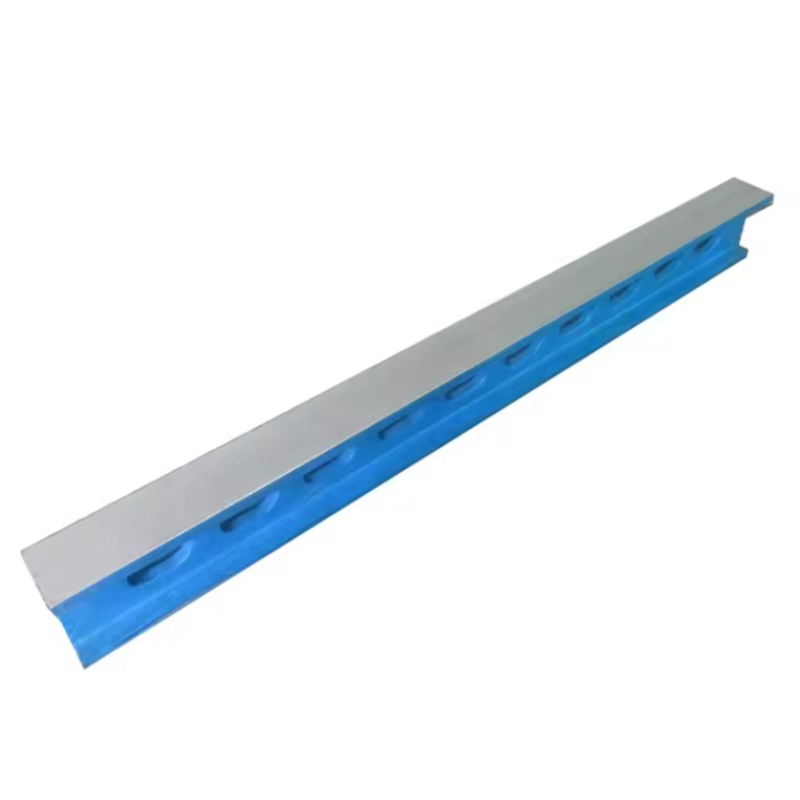

platform inspection

3. Thermographic Inspections Infrared cameras are used to detect temperature variations in equipment, which can indicate underlying problems such as insulation failures or mechanical issues. This method is non-invasive and effective for identifying issues before they lead to equipment failure.

4. Data Analytics and IoT The advent of the Internet of Things (IoT) has revolutionized platform inspections. Sensors embedded in machinery can collect real-time data regarding operational conditions, alerting teams to potential discrepancies that require attention. Data analytics then processes this information to predict maintenance needs and prevent failures.

5. Drone Inspections Drones are increasingly being employed for inspecting hard-to-reach areas, such as tall structures or offshore platforms. They offer a safe and efficient means of conducting inspections, capturing high-resolution imagery, and providing data for analysis without putting human inspectors at risk.

The Role of Technology in Inspection Processes

As technology evolves, so do the tools and techniques available for platform inspection. The integration of advanced technologies, such as artificial intelligence (AI) and machine learning, enhances the inspection process by enabling predictive maintenance. By analyzing historical data patterns, AI systems can foresee potential failures and prompt timely interventions. This shift from reactive to proactive maintenance significantly reduces downtime and maintenance costs.

Moreover, augmented reality (AR) is beginning to play a role in training inspectors and assisting them in conducting inspections. Through AR applications, inspectors can overlay digital information onto the physical world, improving their understanding of complex systems and guiding them during the inspection process.

Conclusion

In conclusion, platform inspection is an indispensable element of safety, quality control, and operational efficiency in various industries. As technology continues to advance, the methodologies employed in inspections will likely evolve, offering even more efficient and effective ways to monitor and maintain industrial platforms. By prioritizing rigorous inspection programs, organizations can mitigate risks, ensure compliance, and enhance their overall operational performance. As the industry moves forward, the commitment to safety through thorough inspection will remain a cornerstone of responsible and sustainable business practices.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS