Nov . 30, 2024 18:33 Back to list

Hydraulic Pilot Check Valve Functionality and Applications in Fluid Control Systems

Understanding Pilot Check Valves in Hydraulic Systems

In the realm of hydraulic systems, precision and reliability are paramount. Among the critical components that ensure consistent performance are pilot check valves. These valves play a crucial role in controlling flow and pressure within hydraulic circuits, enhancing both efficiency and safety.

What are Pilot Check Valves?

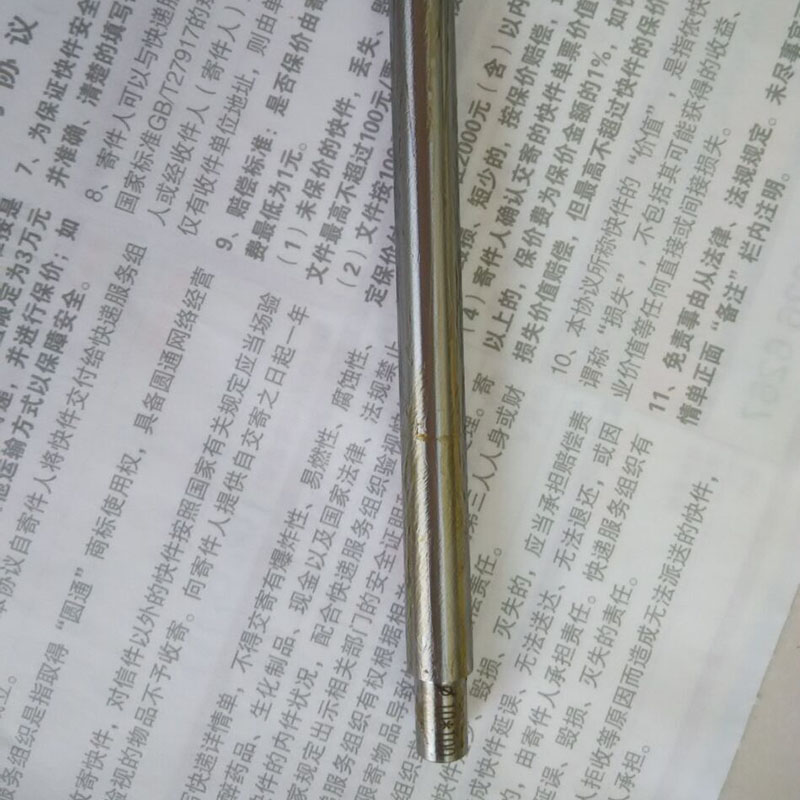

Pilot check valves are specialized one-way valves that allow fluid to flow in a designated direction while preventing backflow. They are often used in conjunction with pilot signals, which enable them to open or close under specific pressures. This functionality makes them indispensable in applications where fluid needs to be controlled dynamically, such as in robotics, industrial machinery, and mobile equipment.

The design of a pilot check valve typically includes two ports the inlet and the outlet. When pressure from the inlet exceeds a certain threshold, the valve opens, allowing fluid to flow through. Conversely, if the pressure at the outlet exceeds that at the inlet, the valve automatically closes, preventing backflow. This functionality helps maintain the integrity of the hydraulic system and protects upstream components from potential damage.

Applications and Benefits

Pilot check valves are extensively used in various applications where precise control of hydraulic fluid is necessary. Common industries that employ these valves include construction, automotive, aerospace, and manufacturing.

pilot check valve hydraulic

One of the primary benefits of pilot check valves is their ability to improve system efficiency. By allowing fluid to bypass certain components when not in use, these valves can help reduce energy consumption and minimize wear and tear on hydraulic pumps and motors. This efficiency translates to lower operational costs and extended equipment lifespan.

Another significant advantage of pilot check valves is their contribution to safety within hydraulic systems. By preventing backflow, they help mitigate risks associated with hydraulic surges and pressure fluctuations, which can lead to component failure or catastrophic system malfunctions. This reliability is especially critical in applications involving heavy machinery and complex systems, where a single failure can result in costly downtime and potential hazards.

Installation and Maintenance

The installation of pilot check valves requires careful consideration of the hydraulic circuit design. It is essential to position the valve correctly to ensure optimal performance. Typically, these valves are mounted inline, with the flow directed according to the manufacturer’s specifications. Additionally, the selection of an appropriate pilot signal pressure is vital for the effective operation of the valve.

Regular maintenance of pilot check valves is also crucial to ensure their longevity and reliability. Routine inspections should be conducted to check for signs of wear, leaks, or debris accumulation that could impede functionality. Cleaning and, if necessary, replacing components can help maintain peak performance and prevent unexpected failures.

Conclusion

In summary, pilot check valves are integral components of hydraulic systems, providing essential control over fluid flow and pressure. Their ability to enhance efficiency and safety makes them a popular choice across various industries. By understanding their function, applications, and maintenance requirements, engineers and operators can leverage pilot check valves to optimize hydraulic systems, ensuring they operate smoothly and reliably for years to come. As technology advances, the evolution of pilot check valves will likely continue, bringing forth innovations that further elevate the performance of hydraulic systems globally.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS