Aug . 08, 2024 15:50 Back to list

Optimal Performance and Durability of 48-Inch Butterfly Valve for Industrial Applications

The Importance and Functionality of 48-Inch Butterfly Valves

In various industrial applications, controlling the flow of fluids is essential for maintaining operational efficiency and safety. Among the many types of valves available, the butterfly valve stands out due to its unique design, which offers numerous advantages for both large and small scale systems. In particular, the 48-inch butterfly valve plays a crucial role in managing fluid flow in large pipelines and processing facilities.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that uses a rotating disc to regulate flow. The design consists of a circular disc or vane mounted on a rod, which pivots within the pipe. When the valve is closed, the disc blocks the fluid flow; when it is open, the disc is aligned with the flow path, allowing fluids to pass with minimal resistance. Butterfly valves are highly efficient in terms of space and weight, particularly in larger sizes, such as the 48-inch variety.

Applications of 48-Inch Butterfly Valves

48-inch butterfly valves are commonly employed across a range of industries, including water treatment, chemical processing, oil and gas, and power generation. Their ability to provide quick on/off control while minimizing pressure drop makes them suitable for both isolation and throttling applications.

In water treatment facilities, for example, butterfly valves are used to control the flow of water through different stages of the purification process. Similarly, in chemical plants, these valves manage the flow of various corrosive and hazardous fluids, ensuring safe and efficient operation. In industries such as HVAC (heating, ventilation, and air conditioning), 48-inch butterfly valves help in regulating airflow and maintaining optimal pressure.

Advantages of 48-Inch Butterfly Valves

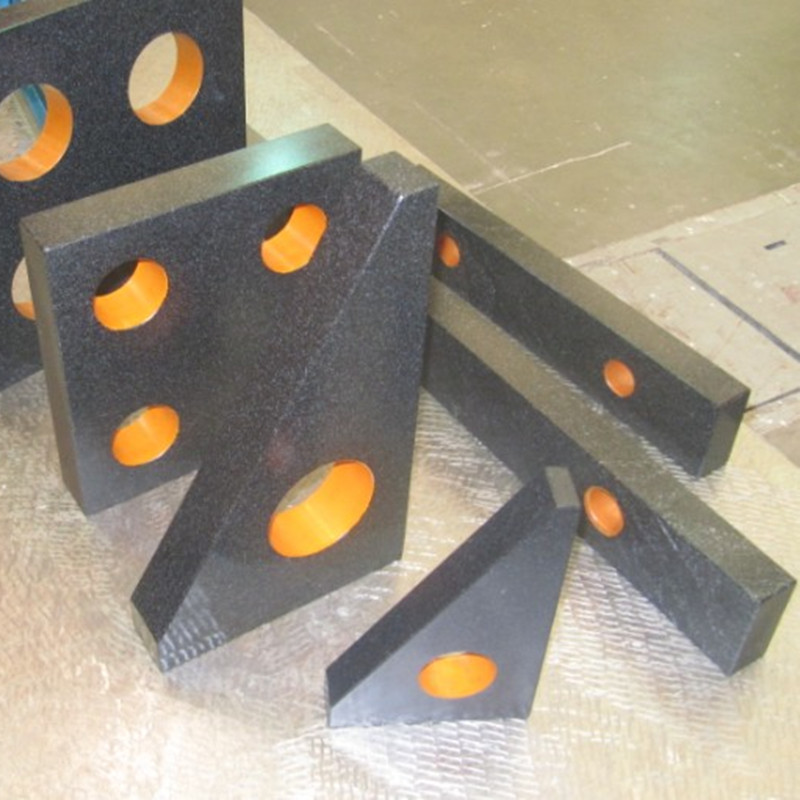

48 inch butterfly valve

One of the key advantages of using a 48-inch butterfly valve is its compact design. Compared to gate or globe valves, butterfly valves occupy less space and are lighter, which simplifies installation and maintenance. Their design allows for easy operation, often requiring only a quarter turn to open or close, which can be advantageous in facilities where quick adjustments are necessary.

Additionally, butterfly valves are generally more cost-effective than other types of large valves. They feature fewer parts and are simpler in construction, leading to reduced manufacturing and installation costs. Despite their lower cost, high-quality butterfly valves can provide excellent performance and durability, particularly when constructed from robust materials such as stainless steel or ductile iron, designed to withstand harsh operating conditions.

Considerations for Selection and Maintenance

When selecting a 48-inch butterfly valve, several factors must be considered, including the type of fluid being controlled, the pressure and temperature conditions, and the specific application requirements. It's essential to choose a valve that meets industry standards and is compatible with the media to ensure safety and reliability.

Routine maintenance is also critical to ensure the longevity and proper functionality of the valve. Regular inspections for wear and tear, checking seals for leaks, and ensuring that the actuator functions smoothly can prevent unexpected failures and costly downtime.

Conclusion

The 48-inch butterfly valve is a vital component in the efficient management of fluid flow in large-scale industrial operations. With its compact design, cost-effectiveness, and suitability for a wide range of applications, it has become an indispensable tool across various sectors. As industries continue to evolve and demand more efficient solutions, the importance of reliable valves, such as the 48-inch butterfly valve, will undoubtedly grow, ensuring safe and controlled operations for years to come.

-

Valves in Water Treatment PlantsNewsJul.07,2025

-

Safety Precautions When Installing Control ValvesNewsJul.07,2025

-

Importance of Routine Inspections for Ball Type Check ValvesNewsJul.07,2025

-

Function and Operation of 1 1 2 Gate ValvesNewsJul.07,2025

-

Enhancing the Performance of 1 1 2 Inch Check ValvesNewsJul.07,2025

-

DN50 Filter Water Valves in Municipal Water TreatmentNewsJul.07,2025

Related PRODUCTS