Aug . 30, 2024 06:33 Back to list

Premium Metal V Blocks for Precision Machining | Your Company Name

Metal vs. Block An In-Depth Comparison in Modern Applications

In the ever-evolving realm of materials science, the choice between metal and composite blocks has become a critical topic for engineers and designers alike. Each material comes with its own set of advantages and challenges, which can significantly influence the performance, durability, and cost-effectiveness of a project.

Metal vs

. Block An In-Depth Comparison in Modern ApplicationsHowever, metals do come with their downsides. They can be heavy, leading to increased weight in applications where reducing mass is crucial. Additionally, metals are susceptible to corrosion, which can compromise their integrity over time, especially in harsh environments. Engineers often need to consider protective coatings or alloying elements to mitigate these issues, which can add to the cost and complexity of projects.

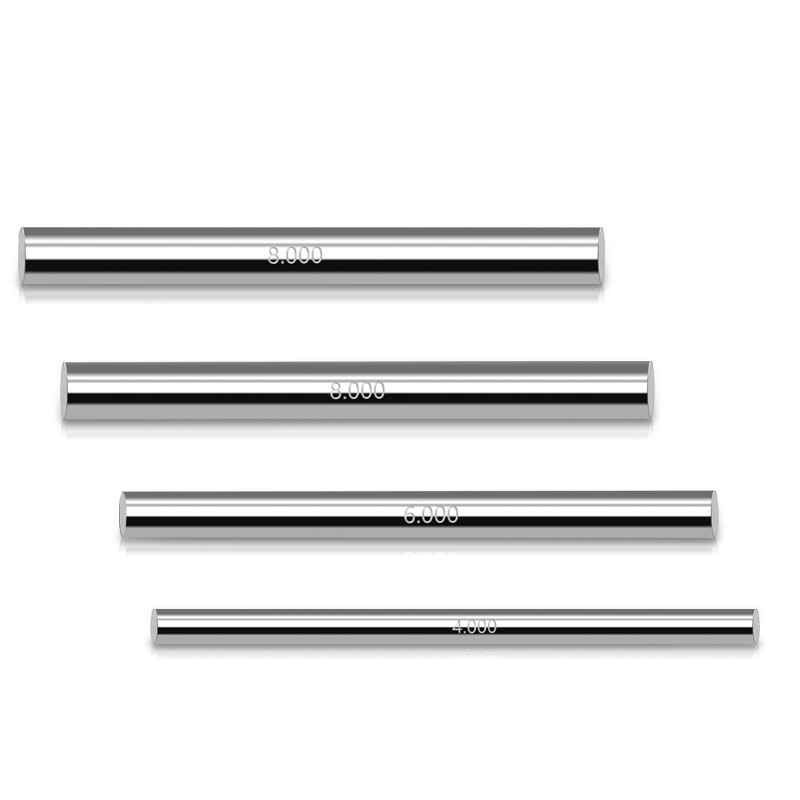

metal v block

On the other hand, block materials—often referring to composite blocks—have gained popularity in recent years. Composites, made from a combination of materials such as plastics, fibers, and resins, offer exceptional lightweight properties without sacrificing strength. This characteristic has led to their widespread use in industries like sports equipment, marine applications, and even in some aerospace components.

One notable advantage of composite blocks is their resistance to corrosion and environmental degradation. The non-metallic nature of these materials allows them to perform well in scenarios where metals would typically fail, such as exposure to saltwater or chemical environments. Moreover, composites can be engineered to exhibit specific properties tailored to particular applications, providing designers with unparalleled flexibility.

However, the use of composite blocks is not without limitations. The manufacturing processes for composites can be more intricate and costly, especially when it comes to ensuring consistent quality and performance. Additionally, the repair of composite materials can be more challenging than traditional metal repairs, necessitating specialized knowledge and techniques.

In conclusion, the choice between metal and block materials ultimately hinges on the specific requirements of a project. Metals provide unmatched strength and proven engineering benefits, while composites offer versatility and resistance to environmental challenges. Understanding the unique properties of each material allows engineers to make informed decisions that align with their project goals, ensuring optimal performance and longevity. As advancements continue in both fields, the debate between metal and block will undoubtedly keep evolving, highlighting the importance of innovation in materials science.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS