Sep . 07, 2024 05:42 Back to list

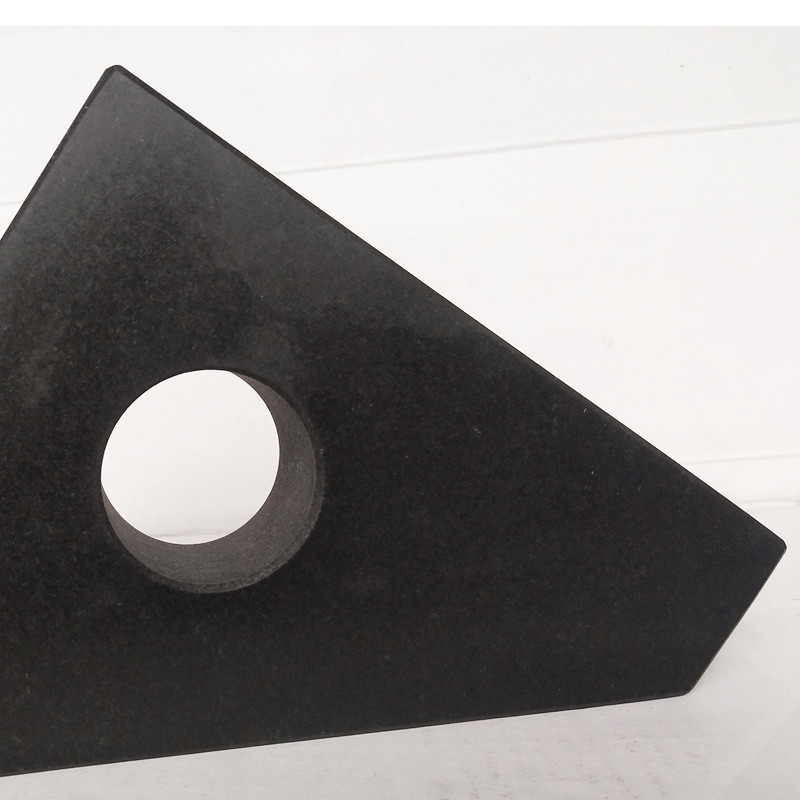

Precision Metal Fabrication Protractor for Accurate Measurements

The Importance of Precision in Metal Fabrication A Closer Look at Protractors

Metal fabrication is a vital industry that involves the creation of metal structures and parts through processes such as cutting, bending, and assembling. The accuracy of these processes is crucial, as any mistake can lead to significant errors in the final product, potentially compromising its structural integrity and functionality. This is where tools like the protractor come into play, serving as indispensable aids in ensuring precision during fabrication.

The Importance of Precision in Metal Fabrication A Closer Look at Protractors

When it comes to metal fabrication, achieving precise angles is often a critical requirement. For example, when fabricating structural frames or supports, the angles between different components must be exact to ensure that the entire structure remains stable and does not weaken over time. A protractor allows fabricators to measure these angles accurately, thereby mitigating risks associated with structural failures.

metal fabrication protractor

In addition to ensuring accuracy, the use of a protractor can significantly streamline the fabrication process. By providing a reliable means for measuring angles as metal pieces are being shaped and fitted together, workers can save time that would otherwise be lost to trial and error. This increased efficiency not only enhances productivity but also minimizes waste materials, as fewer mistakes lead to less scrap metal.

Moreover, the precision achieved with the use of protractors contributes to the overall quality of metal products. High-quality fabrication often results in better-performing end-products, which can lead to increased customer satisfaction and repeat business. In industries where safety is paramount, such as construction and aerospace, the implications of precise metal fabrication cannot be overstated.

In recent years, the integration of Computer Numerical Control (CNC) machines into metal fabrication has further underscored the importance of precision instruments like protractors. Even as technology advances, the foundational principles of measurement remain critical. CNC machines can perform complex tasks with incredible accuracy; however, they rely heavily on the initial input of precise measurements provided by tools like protractors and other measuring devices.

In conclusion, the importance of protractors in metal fabrication cannot be overlooked. They play a vital role in ensuring accuracy, enhancing productivity, and improving the overall quality of fabricated metal products. As the industry continues to evolve, these traditional tools can seamlessly integrate with modern technology to create a more efficient and precise fabrication process. Whether through manual measuring or integrating with advanced machinery, the legacy of the protractor in metal fabrication remains a testament to the industry's commitment to precision and quality.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS