Dec . 18, 2024 16:03 Back to list

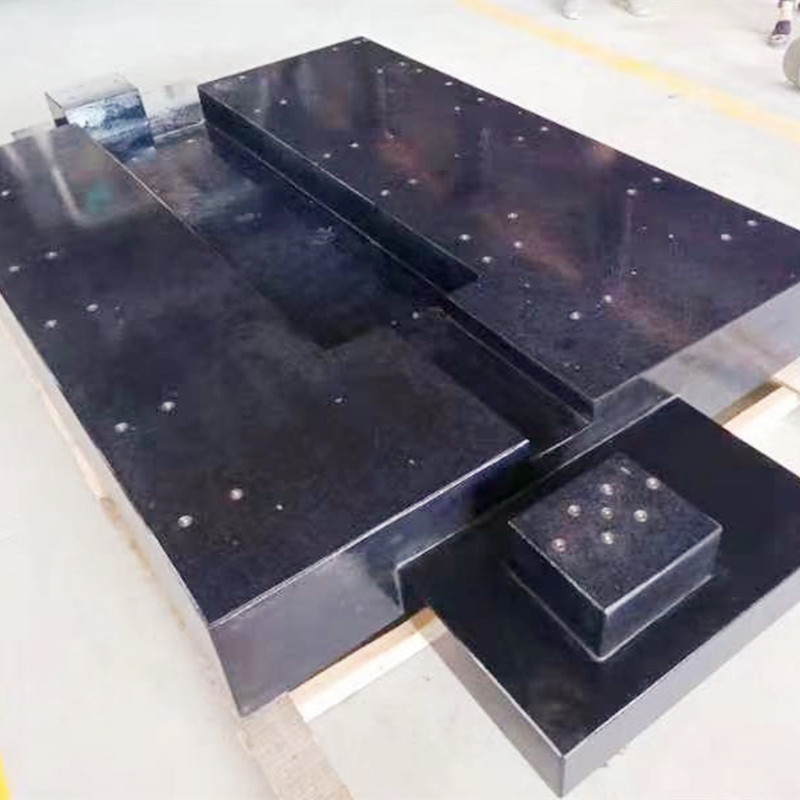

measuring pin gauge

Understanding Measuring Pin Gauges A Comprehensive Overview

Measuring pin gauges are essential precision tools used in various fields, including manufacturing, engineering, and quality control. They play a critical role in ensuring the accuracy and reliability of measurements, which can significantly affect the performance and quality of products. This article delves into pin gauges, their types, applications, and the importance of precise measurement in industrial settings.

What Are Measuring Pin Gauges?

Measuring pin gauges are slender, cylindrical tools that act as reference standards for internal and external measurements. They are typically made from high-quality materials such as stainless steel or tungsten carbide to ensure durability and resistance to wear. The dimensions of these pins are standardized and marked on their bodies for easy identification.

Pin gauges are primarily used to verify the size, form, and dimensions of holes, slots, and other features in workpieces. They provide a simple and effective method for checking tolerances and ensuring that parts meet specified design criteria. The use of pin gauges simplifies the inspection process by allowing operators to quickly determine if a component conforms to its intended specifications.

Types of Pin Gauges

Measuring pin gauges come in various types, each designed for specific measurements

1. Go/No-Go Gauges This is the most common type of pin gauge. Go gauges are used to check whether a feature is within acceptable limits, while No-Go gauges ensure that a part does not exceed specified dimensions. By using both types, manufacturers can easily determine whether components meet tolerances.

2. Fixed Diameter Gauges These gauges have a specific diameter and are used to measure the size of holes or openings in parts. They are often graded into sets to cover a range of dimensions, allowing for versatile usage in various applications.

3. Adjustable Pin Gauges These are designed to be adjustable, allowing users to set them to specific measurements. They provide flexibility in applications where various sizes are needed.

measuring pin gauge

4. Tapered Pin Gauges These gauges are tapered at one end, making them suitable for measuring larger and irregularly shaped holes. Their tapered nature allows for easy insertion and alignment.

Applications of Measuring Pin Gauges

The versatility of pin gauges extends across multiple industries. They are commonly used in machining and fabrication processes to

1. Quality Control Pin gauges are vital in quality control departments, where they ensure that manufactured parts meet required specifications. Regular calibration and verification using these gauges help maintain high standards in production.

2. Machining Operations During machining processes, pin gauges help confirm the accuracy of drilled holes, ensuring they align with engineering designs. This is crucial in industries such as aerospace, automotive, and electronics, where precision is paramount.

3. Assembly Processes In assembly lines, pin gauges help determine whether components fit together as intended. This is especially important in applications like fitting gears, shafts, and other mechanical parts.

4. Maintenance and Repair Technicians use pin gauges to assess wear and damage in parts during maintenance checks. This ensures that they replace or repair components before they fail, thereby extending the overall lifespan of machinery.

Conclusion

Measuring pin gauges are indispensable tools in the realm of precision measurement and quality assurance. By providing a simple yet effective means of verifying dimensions and tolerances, they play a pivotal role in maintaining product integrity and performance across various industries. As manufacturing processes become more sophisticated, the need for accurate measurement tools like pin gauges will continue to grow, highlighting their importance in modern engineering practices. Investing in high-quality pin gauges and understanding their applications can significantly enhance productivity, efficiency, and quality in any manufacturing environment.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS