Feb . 19, 2025 11:02 Back to list

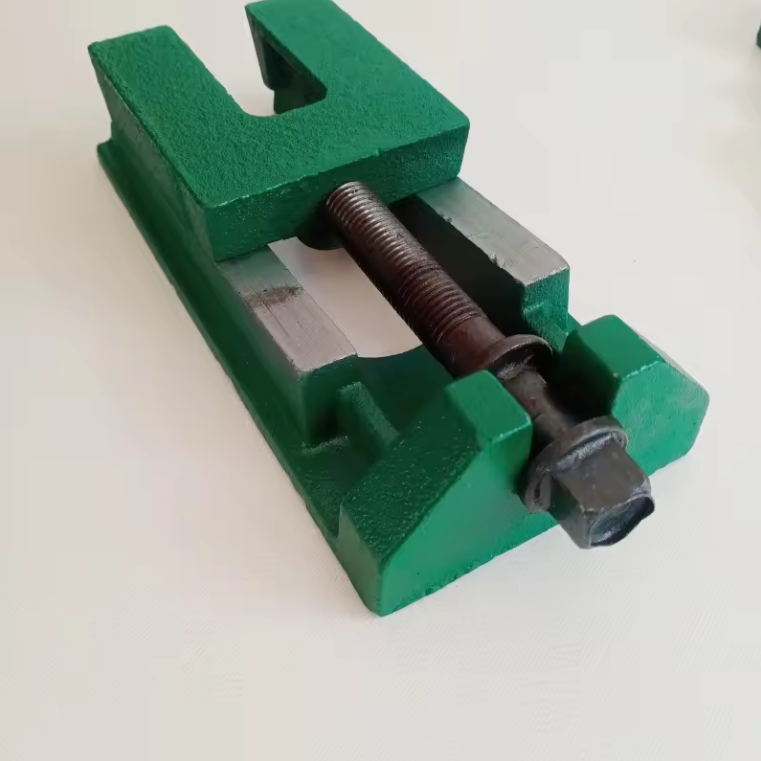

Magnetic V Block

Magnetic V blocks are a ubiquitous tool in any industrial setting where precision and accuracy are paramount. These small, yet incredibly powerful devices are invaluable in machining, quality control, and inspection processes involving cylindrical workpieces. Their ingenious design and functionality provide a foolproof method of securing and supporting round components, ultimately enhancing workflow efficiency and precision measurement.

In terms of expertise, it's crucial to handle magnetic V blocks with care to maintain their functionality and longevity. Proper maintenance practices, such as cleaning the blocks regularly to remove any metal shavings or debris and checking for wear on the V surfaces, can prevent measurement errors and enhance the tool's lifespan. Calibrating these blocks periodically also ensures the utmost precision and accuracy in all applications. As a testament to the authoritativeness of magnetic V blocks, numerous industry standards and guidelines recognize their utility. These tools conform to stringent manufacturing benchmarks, assuring users of their reliability and efficacy. Moreover, respected publications and industrial bodies frequently cite magnetic V blocks as essential equipment for precision engineering and quality assurance processes, further cementing their status as a trusted solution in precision machining environments. Trustworthiness in the context of magnetic V blocks emerges from their proven track record and widespread adoption across various industries. The consistent performance that these tools deliver speaks volumes about their reliability. Users can trust that their investment in such tools will yield returns in the form of increased measurement accuracy, reduced wastage, and enhanced operational efficiency. To sum up, magnetic V blocks stand as a testament to precision engineering, merging simplicity with high functionality. Their ability to secure cylindrical workpieces across different applications is unmatched, making them a critical asset for ensuring the highest accuracy in machining and inspection tasks. Through choosing the right type, maintaining them diligently, and understanding their working principles, workers in industrial settings can harness the power of magnetic V blocks to bolster productivity and quality output seamlessly.

In terms of expertise, it's crucial to handle magnetic V blocks with care to maintain their functionality and longevity. Proper maintenance practices, such as cleaning the blocks regularly to remove any metal shavings or debris and checking for wear on the V surfaces, can prevent measurement errors and enhance the tool's lifespan. Calibrating these blocks periodically also ensures the utmost precision and accuracy in all applications. As a testament to the authoritativeness of magnetic V blocks, numerous industry standards and guidelines recognize their utility. These tools conform to stringent manufacturing benchmarks, assuring users of their reliability and efficacy. Moreover, respected publications and industrial bodies frequently cite magnetic V blocks as essential equipment for precision engineering and quality assurance processes, further cementing their status as a trusted solution in precision machining environments. Trustworthiness in the context of magnetic V blocks emerges from their proven track record and widespread adoption across various industries. The consistent performance that these tools deliver speaks volumes about their reliability. Users can trust that their investment in such tools will yield returns in the form of increased measurement accuracy, reduced wastage, and enhanced operational efficiency. To sum up, magnetic V blocks stand as a testament to precision engineering, merging simplicity with high functionality. Their ability to secure cylindrical workpieces across different applications is unmatched, making them a critical asset for ensuring the highest accuracy in machining and inspection tasks. Through choosing the right type, maintaining them diligently, and understanding their working principles, workers in industrial settings can harness the power of magnetic V blocks to bolster productivity and quality output seamlessly.

Next:

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS