Dec . 04, 2024 09:05 Back to list

large v blocks

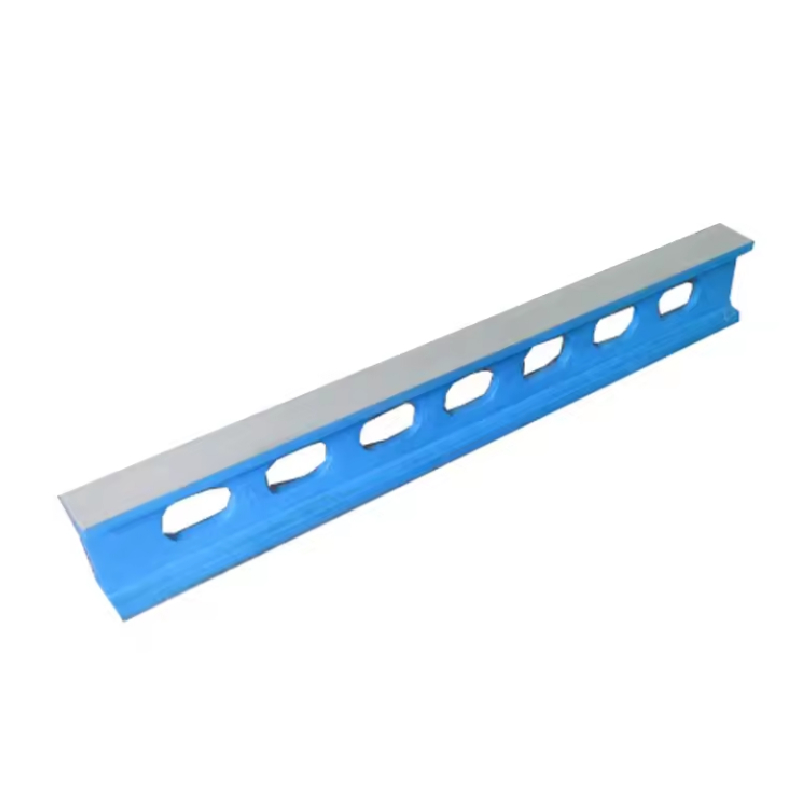

Understanding Large V Blocks A Comprehensive Overview

In the realm of machining and manufacturing, precision, reliability, and efficiency are paramount. One of the essential tools that play a critical role in achieving these goals is the large V block. These versatile fixtures are primarily used in the setup and clamping of workpieces, particularly those that are cylindrical or irregularly shaped. In this article, we will explore the features, applications, advantages, and best practices associated with large V blocks.

What is a Large V Block?

A large V block is a tool made of high-quality materials such as hardened steel or cast iron. Its design features a V-shaped groove that allows for the secure holding of cylindrical parts, enabling machinists to perform various operations such as cutting, drilling, or welding. The size of these blocks can vary widely, with larger versions often utilized in industrial settings for big components.

Applications of Large V Blocks

Large V blocks find their applications across various industries, including automotive, aerospace, construction, and metal fabrication. Here are some of their key uses

1. Machining They provide a stable base for machining operations on cylindrical workpieces, ensuring accuracy in dimension and alignment. 2. Inspection Quality control inspectors use large V blocks to check the straightness and tolerances of cylindrical items, ensuring they meet specific standards.

3. Assembly In the assembly of components, large V blocks assist in accurately positioning parts for welding or fastening.

Advantages of Using Large V Blocks

The use of large V blocks offers multiple benefits, contributing to improved efficiency and precision in machining

1. Improved Stability Their design gives excellent support to cylindrical components, reducing the risk of movement during machining processes.

large v blocks

2. Enhanced Precision The accurate alignment provided by V blocks translates to higher precision in machining, which is crucial for fulfilling strict tolerances.

3. Versatility Large V blocks can accommodate various sizes and shapes of workpieces, making them suitable for diverse applications.

4. Durability Typically made from robust materials, large V blocks are designed to withstand repetitive use and heavy loads without compromising on performance.

Best Practices for Using Large V Blocks

To maximize the effectiveness of large V blocks, it is crucial to observe some best practices

1. Surface Preparation Ensure that the surfaces of both the V block and the workpiece are clean and free from debris to promote better contact and stability.

2. Proper Alignment Take the time to align the workpiece accurately within the V groove to achieve optimal support and precision.

3. Secure Clamping Use appropriate clamping techniques to fix the workpiece in place securely. Avoid over-tightening as it may damage either the block or the workpiece.

4. Regular Maintenance Maintain the V blocks by routinely checking for wear and tear, and clean them to prevent the accumulation of metal shavings and dirt.

Conclusion

Large V blocks serve as indispensable tools in the machining and manufacturing industries, aiding in the accurate positioning and stabilization of cylindrical workpieces. Their robust design, adaptability, and precision capabilities make them invaluable for a variety of applications. By understanding their features and adhering to best practices, professionals can ensure they get the most out of their large V blocks, leading to enhanced productivity and quality in their work processes.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS