Aug . 15, 2024 02:43 Back to list

Innovative Techniques for Measuring Performance and Enhancing Efficiency in Various Industries

Understanding Gauge A Key Concept in Measurement and Performance

Gauge, at its core, refers to a measurement tool or a standard used for determining the size, amount, or capacity of various materials. Whether in engineering, manufacturing, or everyday life, the concept of gauge is integral to ensuring accuracy and consistency. From the thickness of metal sheets to the pressure in pipes, gauges play a vital role in various industries. This article delves into the significance of gauges, their types, and their applications across different fields.

One of the most common applications of gauges can be found in the automotive industry, where they are used to measure everything from tire pressure to fuel levels. For instance, a tire pressure gauge is essential for maintaining optimal tire inflation, which affects vehicle performance, fuel efficiency, and safety. A correctly inflated tire can enhance handling, reduce wear, and improve fuel economy. On the other hand, an under-inflated tire can lead to blowouts and accidents, underscoring the importance of having reliable measuring tools.

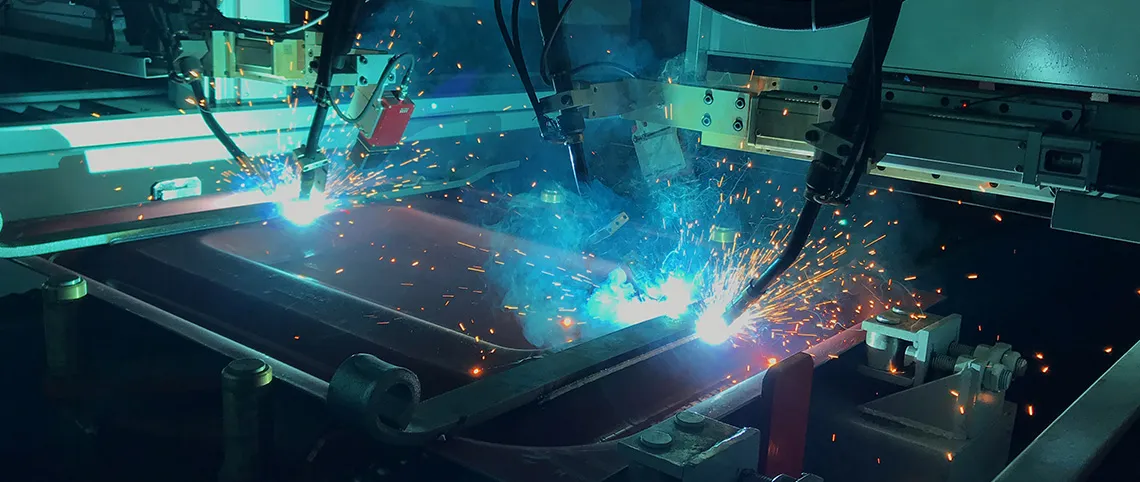

In manufacturing processes, gauges are employed to ensure that components meet specified tolerances and quality standards. Calipers, micrometers, and gauge blocks are some tools that allow engineers and machinists to measure dimensions with precision. The use of these tools helps in error reduction during production, which can save time and resources in the long run. In fields such as aerospace and electronics, where the slightest deviation can have catastrophic consequences, the importance of accurate gauging cannot be overstated.

Gauges are not limited to linear measurements; they also extend to other physical properties. Pressure gauges, for example, monitor pressure in systems ranging from water supply networks to HVAC systems. In these scenarios, maintaining the right pressure is essential for operational efficiency and safety. A failure to monitor and adjust pressure appropriately can lead to leaks, bursts, or equipment failure, emphasizing the critical role of gauges in various applications.

gauge

Another fascinating aspect of gauges is their utilization in the field of science. In laboratories, scientists often rely on gauges to measure temperature, pH levels, and other vital parameters during experiments. These measurements are crucial for ensuring that experiments yield valid results and can be reliably reproduced. Precision in scientific measurements contributes directly to the advancement of knowledge and technology, highlighting the broader implications of gauges beyond industrial applications.

The digital evolution has also transformed the landscape of gauging. Modern digital gauges provide more precise readings and often include data logging capabilities, which enable users to track changes over time. This innovation aids in predictive maintenance, where anomalies can be detected early, ensuring machines operate efficiently and prolonging their lifespan.

However, while gauges are indispensable, users must be trained to employ them correctly. Misinterpretation of gauge readings can lead to dangerous outcomes, particularly in fields that demand high levels of safety, such as aviation and chemical processing. Regular calibration and maintenance of gauges are also vital to ensure their accuracy over time.

In conclusion, the concept of gauge is a fundamental aspect of measurement that permeates various industries and scientific disciplines. From enhancing vehicle safety to ensuring precision in manufacturing and improving laboratory accuracy, gauges are crucial for operational efficiency and safety. As technology advances, the tools and methodologies associated with gauging continue to evolve, reinforcing the importance of precise measurement in a world increasingly reliant on data-driven decisions. Understanding gauge, therefore, is not just about mastering a measurement tool; it is about embracing a foundational principle that encourages quality and innovation across disciplines.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS