Aug . 06, 2024 09:16 Back to list

Innovative Techniques and Processes in Metal Table Fabrication for Modern Design Solutions

Understanding Metal Table Fabrication A Comprehensive Overview

Metal table fabrication is a specialized process that involves the design, cutting, shaping, and assembly of metal components to create durable and functional tables for various applications. This process is pivotal in industries ranging from construction and manufacturing to interior design, where aesthetics, strength, and usability are paramount.

The Fabrication Process

The metal table fabrication process typically begins with design. Utilizing advanced computer-aided design (CAD) software, fabricators can create detailed models of the tables they intend to produce. This stage allows for customization according to client specifications, including dimensions, materials, finishes, and any additional features like drawers or extensions.

Once the design is finalized, the next step is material selection. Common materials used in metal table fabrication include stainless steel, aluminum, and carbon steel, each offering unique properties. Stainless steel is favored for its resistance to corrosion and rust, making it ideal for outdoor tables or kitchen environments. Aluminum is lightweight yet strong, often used for portable tables, while carbon steel possesses high tensile strength, suitable for heavy-duty applications.

After selecting the appropriate material, the fabrication process continues with cutting. Various techniques are employed, including laser cutting, plasma cutting, and water jet cutting. Each method has its advantages, with laser cutting providing precise and clean edges, while plasma cutting offers speed and efficiency for thicker materials.

Following cutting, shaping and assembling come into play. Shaping processes can involve bending, welding, and machining, depending on the table’s design requirements. Welding is particularly crucial as it ensures the structural integrity of the table, binding different metal parts securely. Advanced welding techniques, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, are frequently used to achieve strong and aesthetically pleasing joints.

Surface Finishing

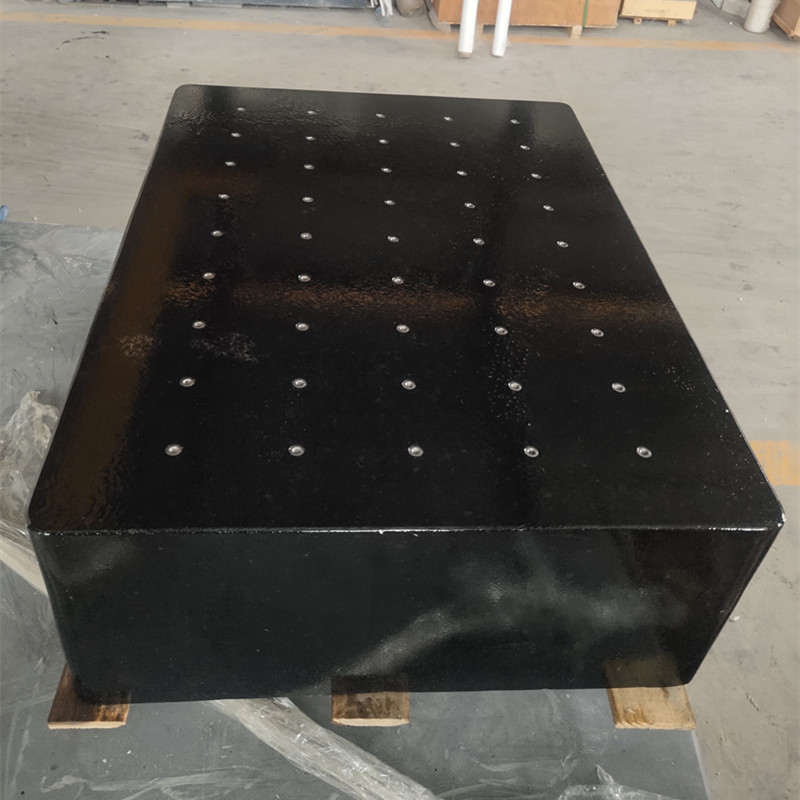

metal table fabrication

Once the basic structure is complete, surface finishing is applied to enhance both the appearance and durability of the table. Methods such as grinding, polishing, and powder coating can be employed. Powder coating is a popular choice as it provides a protective layer that is both visually appealing and resistant to scratches and corrosion. Additionally, anodizing aluminum tables improves their resistance to wear and adds an attractive finish.

Applications of Metal Tables

Metal tables are utilized in numerous environments. In commercial settings, they are common in restaurants, cafes, and offices due to their durability and ease of cleaning. Custom designs can reflect the branding of a business while ensuring functionality. In industrial settings, heavy-duty metal tables serve as workstations for assembly lines, providing stable surfaces for machinery and tools.

Sustainability in Metal Fabrication

As sustainability becomes increasingly important, metal table fabrication is also evolving. Recyclable materials are now a significant focus, and many manufacturers are adopting eco-friendly practices in their processes. Using recycled metals not only reduces waste but also minimizes the carbon footprint associated with material production.

Conclusion

Metal table fabrication is an intricate process that combines artistry with engineering. From the initial design phase to the final finishing touches, each step is crucial in producing tables that are not only functional but also visually appealing. As industries continue to demand high-quality, durable, and stylish tables, the importance of skilled metal fabrication will only grow. Ultimately, as technology and sustainable practices advance, the future of metal table fabrication looks promising, paving the way for innovative designs and applications that cater to diverse needs and preferences.

-

Valves in Water Treatment PlantsNewsJul.07,2025

-

Safety Precautions When Installing Control ValvesNewsJul.07,2025

-

Importance of Routine Inspections for Ball Type Check ValvesNewsJul.07,2025

-

Function and Operation of 1 1 2 Gate ValvesNewsJul.07,2025

-

Enhancing the Performance of 1 1 2 Inch Check ValvesNewsJul.07,2025

-

DN50 Filter Water Valves in Municipal Water TreatmentNewsJul.07,2025

Related PRODUCTS