Jul . 31, 2024 01:55 Back to list

Innovative Plastic Rebar Clip Spacer Solutions for Enhanced Construction Durability and Efficiency

The Role of Plastic Rebar Clip Spacers in Modern Construction

In the realm of construction, achieving structural integrity and durability is paramount. Among the various components that contribute to the strength of reinforced concrete, steel rebar plays an essential role. However, the effectiveness of rebar is heavily reliant on its proper placement, which is where plastic rebar clip spacers come into play. These innovative tools have become increasingly popular in the construction industry for a variety of reasons.

Plastic rebar clip spacers are designed to hold rebar in place during the pouring of concrete, ensuring that the rebar remains positioned at the correct elevation and spacing. This is critical for the rebar to effectively perform its function of reinforcing the concrete, as it helps to resist tensile forces that concrete alone cannot. The use of plastic spacers instead of traditional materials, such as steel or concrete, provides several advantages that significantly enhance the quality and efficiency of construction projects.

One of the primary benefits of plastic rebar clip spacers is their lightweight nature. Unlike steel spacers, which can be cumbersome and add unnecessary weight to the formwork, plastic spacers are easy to handle and install. This reduces labor costs and speeds up the construction process, allowing projects to be completed more quickly and efficiently. Additionally, their lightweight properties reduce the overall load on the supporting structures, thereby improving the overall safety of the construction site.

Another significant advantage of plastic spacers is their resistance to corrosion. Steel spacers are susceptible to rust and deterioration over time, especially when exposed to moisture and harsh environmental conditions. On the other hand, plastic spacers are immune to such degradation, ensuring that they retain their structural integrity throughout the lifespan of the concrete structure. This resistance to corrosion not only extends the lifespan of the spacers themselves but also contributes to the longevity of the reinforced concrete, reducing maintenance costs and enhancing durability.

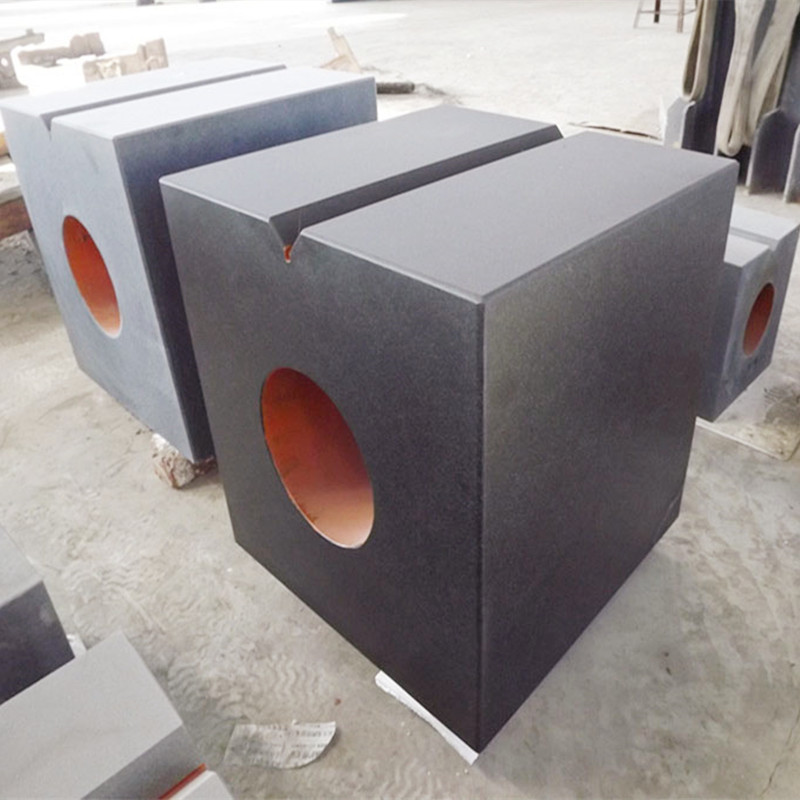

plastic rebar clip spacer

Plastic rebar clip spacers also offer versatility in design and application. They are available in various sizes and shapes to accommodate different rebar configurations and concrete thicknesses. This flexibility makes them suitable for a wide range of construction applications, from residential buildings to large-scale infrastructure projects. The ability to customize spacers according to specific project requirements ensures that they fulfill their role effectively, providing maximum support and stability for the rebar.

Moreover, the installation process for plastic rebar clip spacers is straightforward, further streamlining the construction workflow. Unlike traditional spacers that may require additional tools or complicated setups, plastic spacers can be easily clipped onto the rebar without additional support. This simplicity not only enhances efficiency on-site but also reduces the likelihood of installation errors, which can compromise the overall quality of the concrete structure.

Furthermore, the environmental impact of plastic rebar clip spacers should not be overlooked. Many manufacturers are now producing these spacers from recycled materials, making them a more eco-friendly option compared to other materials. By using recycled plastic, construction companies can contribute to sustainability efforts while still ensuring structural reliability.

In conclusion, plastic rebar clip spacers play a vital role in modern construction by ensuring the correct placement of rebar, thus enhancing the strength and durability of concrete structures. Their lightweight, corrosion-resistant properties, versatility, ease of installation, and potential for eco-friendliness make them a preferred choice among construction professionals. As the industry continues to innovate, the reliance on such practical and efficient tools will undoubtedly grow, paving the way for safer, more durable building practices.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS