Nov . 12, 2024 15:38 Back to list

industrial welding table

The Importance of Industrial Welding Tables in Manufacturing

Industrial welding tables are essential tools in manufacturing environments where precision and quality are paramount. These specialized work surfaces provide a sturdy and reliable platform for fabricating metal components through various welding processes, including MIG, TIG, and stick welding. The importance of a well-designed welding table cannot be overstated, as it greatly influences the efficiency and accuracy of welding operations.

Design and Construction

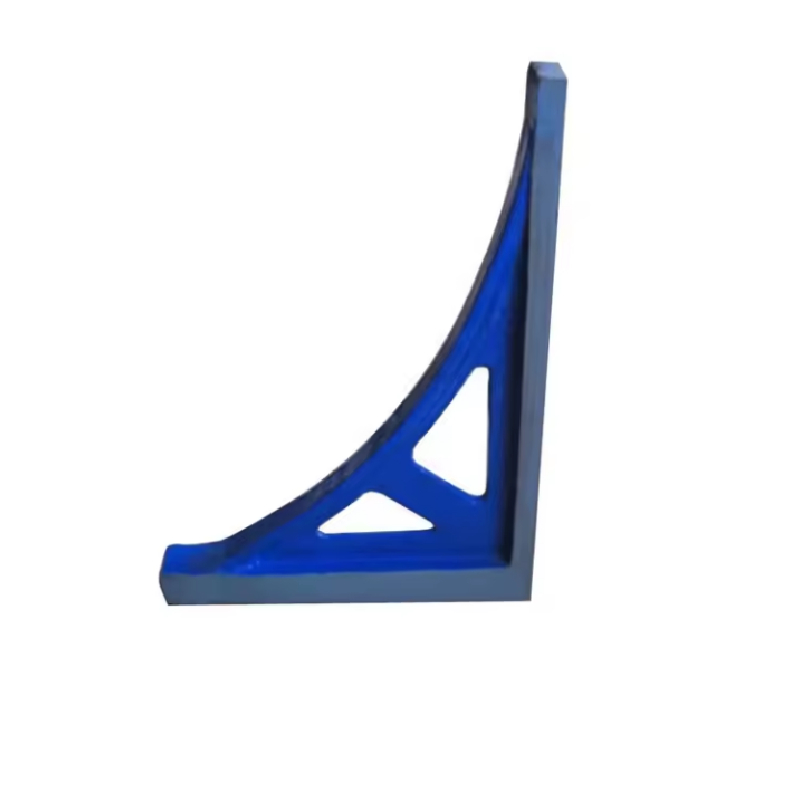

Industrial welding tables are typically constructed from heavy-duty steel or other durable materials designed to withstand the rigors of welding activities. A typical welding table features a flat, even surface, often with integrated clamping devices and adjustable features that allow for versatile setups for different projects. The design may also include slots or holes that facilitate the attachment of fixtures and jigs, which helps in securing workpieces in place during the welding process. These features significantly enhance productivity by reducing setup time and allowing for quicker project turnaround.

Versatility in Applications

One of the standout features of industrial welding tables is their versatility. They can be used in various fields, including automotive manufacturing, construction, and custom fabrication shops. Whether welding heavy steel beams for structural applications or small components for intricate assemblies, a welding table serves as the backbone of the welding process. Additionally, some tables are engineered to accommodate different welding techniques, which allows manufacturers to switch between methods without needing to invest in multiple workstations.

Precision and Accuracy

The level of precision obtainable with a welding table is critical for the integrity of the final product. A level and stable work surface minimizes the risk of deformation or misalignment during the welding process. High-quality welding tables can support significant weight, ensuring that even large components remain firmly in place. This rigidity is essential when working with materials that require exact measurements and joints, ensuring that the final welds are not only strong but also aesthetically pleasing.

industrial welding table

Safety Considerations

Safety is a paramount concern in any welding operation. Industrial welding tables often incorporate features that enhance the safety of the welding environment. For instance, some tables are designed with fire-resistant surfaces and anti-slip coatings, reducing the likelihood of accidents. Furthermore, with organized workspaces, the risk of injury is minimized as tools and materials are kept within easy reach, preventing unnecessary movement around the workspace.

Enhancing Workflow Efficiency

A well-organized welding table can significantly enhance workflow efficiency in a manufacturing environment. By allowing easy access to tools and materials, workers can focus on their tasks rather than searching for equipment. Additionally, the integration of storage options, such as drawers or shelves, can further streamline operations. In turn, this leads to increased productivity, reduced lead times, and ultimately, a more profitable operation.

Customization and Innovation

As industries evolve, so do the needs of manufacturers, leading to innovations in welding table design. Customizable tables allow manufacturers to tailor their workstations to specific applications, accommodating various sizes, materials, and welding methods. Trends such as height-adjustable tables are becoming increasingly popular, allowing operators to work comfortably whether seated or standing. The integration of technology, such as built-in measuring devices and digital displays, is also becoming more common, providing real-time data that can help in achieving consistent welding quality.

Conclusion

In conclusion, industrial welding tables are foundational elements in the manufacturing sector, serving as the nexus of efficiency, precision, and safety in welding operations. Their robust design, versatility, and ability to enhance workflow make them indispensable tools for fabricators. As industries continue to innovate and evolve, the role of welding tables will remain critical, adapting to meet the ever-changing demands of modern manufacturing environments. Investing in high-quality, customizable welding tables is not just a necessity, but a strategic move towards achieving excellence in metal fabrication.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS