Dec . 04, 2024 18:44 Back to list

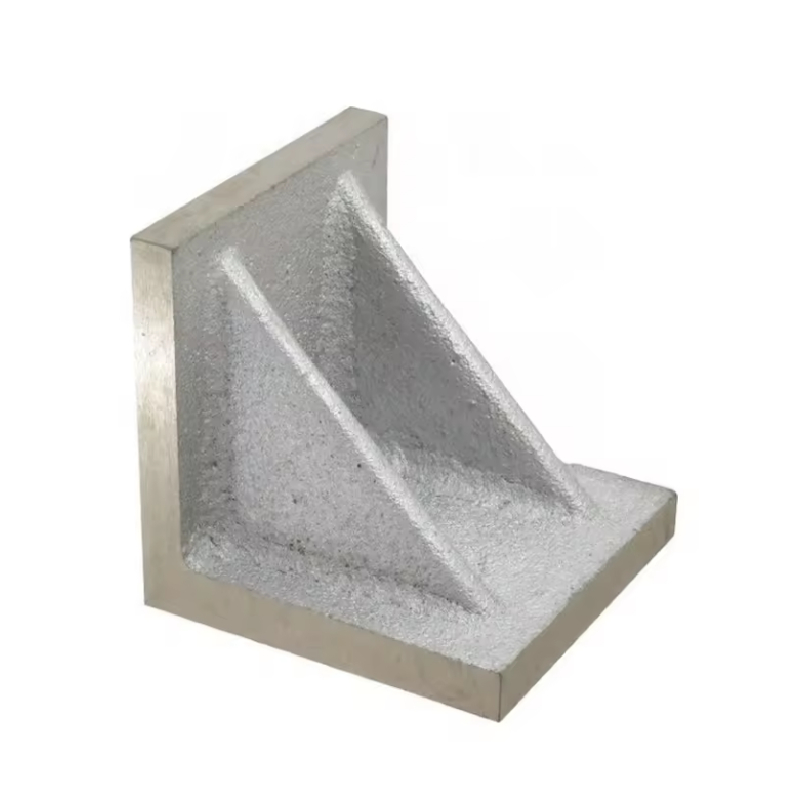

industrial vibration pads

The Importance of Industrial Vibration Pads in Modern Manufacturing

In modern manufacturing and industrial environments, maintaining operational efficiency and equipment longevity is paramount. One often overlooked component in achieving this goal is the use of industrial vibration pads. These specialized pads are designed to absorb and mitigate vibrations produced by machinery, thereby enhancing equipment performance and extending its lifespan. This article delves into the significance of industrial vibration pads, their applications, and the benefits they offer to various industries.

Understanding Vibration and Its Impact

Vibration refers to mechanical oscillations about an equilibrium point. In industrial settings, heavy machinery, pumps, compressors, and generators often generate significant vibrations during operation. If left unchecked, these vibrations can lead to several issues, including mechanical wear, noise pollution, equipment malfunction, and increased maintenance costs. Additionally, excessive vibrations can pose safety risks to personnel and compromise the overall structural integrity of the facility.

The Role of Industrial Vibration Pads

Industrial vibration pads serve as a critical line of defense against the negative effects of vibrations. Typically made from materials such as rubber, neoprene, or polyurethane, these pads act as shock absorbers. They are strategically placed under machines to dampen vibrations and reduce the transfer of energy to the underlying structure.

By isolating vibrations, these pads help maintain a stable operating environment, leading to improved accuracy in manufacturing processes and reducing the likelihood of product defects. Furthermore, they minimize noise levels, contributing to a safer and more comfortable workplace.

Applications Across Industries

The applications of industrial vibration pads are vast and varied. Manufacturing facilities, automotive plants, aerospace industries, and even research laboratories utilize these pads to enhance their operations. For instance, in the automotive industry, vibration pads are crucial during the assembly process, as they help ensure precision when aligning components. In aerospace settings, they provide the necessary stability for sensitive equipment, thus ensuring the integrity of critical measurements.

industrial vibration pads

Moreover, vibration pads find utility in HVAC systems, where they isolate compressor vibrations from the building structure. This not only prolongs the life of the HVAC units but also enhances occupant comfort by minimizing noise disruptions.

Benefits of Using Industrial Vibration Pads

1. Increased Equipment Lifespan By absorbing and dissipating vibrations, these pads significantly reduce wear and tear on machinery. This results in fewer breakdowns and extended operational life for expensive equipment.

2. Enhanced Performance Machines that operate with reduced vibrations tend to perform better, yielding improved precision and quality in production processes.

3. Noise Reduction Industrial environments are often loud, which can be detrimental to worker health and productivity. Vibration pads help lower noise levels, creating a more conducive work environment.

4. Safety Improvements By stabilizing machinery and reducing vibration-related risks, these pads contribute to a safer workplace, reducing the likelihood of accidents and injuries.

5. Cost-Effectiveness Although there is an initial investment in vibration pads, the long-term savings from reduced maintenance costs and increased productivity far outweigh this initial expenditure.

Conclusion

In conclusion, industrial vibration pads are an essential component of modern manufacturing and industrial operations. Their role in mitigating vibrations cannot be understated, as they contribute to equipment longevity, improved operational efficiency, and enhanced workplace safety. As industries continue to evolve and embrace new technologies, the importance of implementing effective vibration control measures, including the use of vibration pads, will only increase. Investing in these pads is not merely a matter of comfort; it is a strategic decision that can yield significant returns in performance and reliability across various industrial applications.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS