Nov . 21, 2024 19:04 Back to list

horizontal ball check valve

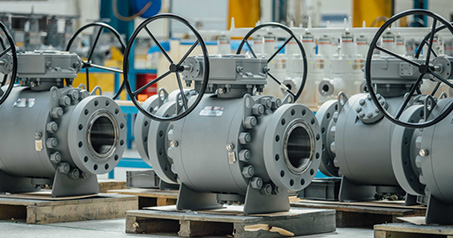

Horizontal Ball Check Valve A Key Component in Fluid Systems

The horizontal ball check valve is a crucial component used in various industrial applications to prevent backflow in fluid systems. Its utility spans numerous sectors, including oil and gas, water treatment, and HVAC systems. This type of check valve is designed to function effectively in horizontal piping systems, ensuring that fluids flow in the intended direction while blocking reverse flow.

One of the primary advantages of the horizontal ball check valve is its simple yet effective design. It consists of a spherical ball that is housed within a valve body. When fluid flows in the designated direction, the ball rests against a seat, allowing fluid to pass through with minimal resistance. If the flow direction reverses, the ball is lifted off the seat, sealing the opening and preventing backflow. This mechanism not only protects the integrity of the system but also helps maintain pressure levels, ensuring smooth operation.

The horizontal aspect of this valve design allows for efficient installation in systems where horizontal pipelines are prevalent. This orientation minimizes the effects of gravity on the ball's movement, enabling quicker response times to changes in flow direction. Additionally, the streamlined shape of the valve reduces turbulence, which can enhance overall system efficiency.

horizontal ball check valve

Materials used in manufacturing horizontal ball check valves vary based on the application and the type of fluid being handled. Common materials include stainless steel, brass, and various plastics. Choosing the right material is essential for ensuring durability and resistance to corrosion, especially in challenging environments such as wastewater management or corrosive chemical processes.

Maintenance of horizontal ball check valves is relatively straightforward. Regular inspections are crucial to ensure that no debris or buildup obstructs the ball's movement. By implementing a routine maintenance schedule, operators can prevent potential failures and extend the valve's lifespan. Moreover, because these valves are generally low maintenance, they are a cost-effective solution for many applications.

In summary, the horizontal ball check valve plays a vital role in maintaining the efficiency and safety of fluid systems. Its simple design, effective operation, and adaptability to various materials make it an essential component across multiple industries. Understanding how these valves work and their benefits can help engineers and operators make informed decisions about their fluid management systems, enhancing operational reliability and efficiency. Whether in a municipal water system or a chemical processing plant, the horizontal ball check valve ensures that fluids flow smoothly and safely, upholding the integrity of the entire system.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS