Jan . 25, 2025 03:28 Back to list

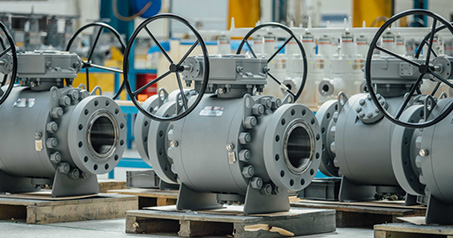

knife gate valve types

High pressure knife gate valves have cemented their place as pivotal components in industries requiring high-stakes fluid control. Constructed to handle several types of flow including solid-laden and abrasive slurries, these valves are indispensable across sectors such as mining, wastewater treatment, and chemical processing. They provide unparalleled reliability and precision in managing heavy-duty processes.

An integral feature that enhances the trustworthiness of knife gate valves is their excellent sealing capabilities. They deliver a tight shut-off, mitigating leakage risks and ensuring safety and efficiency in high-pressure scenarios. The advanced sealing technology ensures that even after repeated cycles, the valve maintains optimal performance, thus proving its reliability across varied applications. Furthermore, these valves provide an authoritative solution to environmental and operational challenges faced by several industries. For instance, in wastewater treatment plants, the ability of high-pressure knife gate valves to handle different kinds of slurry without jamming translates to more predictable and consistent process management, resulting in better environmental compliance and resource optimization. Investing in high-pressure knife gate valves also signals a commitment to adhering to industry standards and best practices. As international regulations continue to favor environmentally and economically sustainable practices, using trusted valve solutions helps companies navigate and adopt these changes smoothly. In summation, high-pressure knife gate valves are not merely a choice but a necessity in any fluid control strategy demanding precision, reliability, and efficiency. Their unmatched design and performance credentials not only address current industrial challenges but also pave the way for future advancements. Through continuous innovation and adherence to strict quality standards, knife gate valves remain at the forefront of engineering excellence, solidifying their role as the staple of fluid management systems across demanding industries.

An integral feature that enhances the trustworthiness of knife gate valves is their excellent sealing capabilities. They deliver a tight shut-off, mitigating leakage risks and ensuring safety and efficiency in high-pressure scenarios. The advanced sealing technology ensures that even after repeated cycles, the valve maintains optimal performance, thus proving its reliability across varied applications. Furthermore, these valves provide an authoritative solution to environmental and operational challenges faced by several industries. For instance, in wastewater treatment plants, the ability of high-pressure knife gate valves to handle different kinds of slurry without jamming translates to more predictable and consistent process management, resulting in better environmental compliance and resource optimization. Investing in high-pressure knife gate valves also signals a commitment to adhering to industry standards and best practices. As international regulations continue to favor environmentally and economically sustainable practices, using trusted valve solutions helps companies navigate and adopt these changes smoothly. In summation, high-pressure knife gate valves are not merely a choice but a necessity in any fluid control strategy demanding precision, reliability, and efficiency. Their unmatched design and performance credentials not only address current industrial challenges but also pave the way for future advancements. Through continuous innovation and adherence to strict quality standards, knife gate valves remain at the forefront of engineering excellence, solidifying their role as the staple of fluid management systems across demanding industries.

Next:

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS