Aug . 09, 2024 00:30 Back to list

High-Quality 3% Stainless Steel Gate Valve for Reliable Fluid Control Applications

Understanding 3% Stainless Steel Gate Valves Characteristics and Applications

Gate valves are essential components in various piping systems, providing an efficient means to control fluid flow. Among the different types of gate valves available, those made from stainless steel, particularly with a composition of 3% nickel or other alloying elements, are widely regarded for their durability and performance in demanding environments. This article explores the features, advantages, and applications of 3% stainless steel gate valves.

Composition and Characteristics

A gate valve is designed to start or stop the flow of liquids or gases in a pipeline. The construction material of the valve significantly influences its performance and longevity. Stainless steel, known for its excellent corrosion resistance, strength, and aesthetic appeal, is a preferred choice for many industries. In particular, stainless steel gate valves with about 3% nickel content enhance the steel’s toughness and resistance to temperature variations, making them suitable for both high and low-temperature applications.

The 3% nickel alloyed stainless steel offers improved mechanical properties compared to standard stainless steel grades. This addition helps prevent embrittlement and increases the valve's ability to withstand extreme conditions. The resistance to pitting and crevice corrosion is particularly beneficial in environments where aggressive fluids are present, such as in chemical processing or marine applications.

Advantages of 3% Stainless Steel Gate Valves

1. Corrosion Resistance The primary advantage of using 3% stainless steel gate valves is their exceptional resistance to corrosion. This makes them ideal for use in harsh environments where chemicals or saline waters are present.

2. Temperature Resilience With a high resistance to both high and low temperatures, these valves can function effectively in a range of thermal conditions, making them suitable for industries like oil and gas, food processing, and power generation.

3. Durability and Longevity The robust construction of 3% stainless steel gate valves ensures a long lifespan, reducing the need for frequent replacements and maintenance. This durability contributes to lower overall operating costs.

3 stainless steel gate valve

4. Smooth Operation Gate valves are designed for linear motion. The disc acts like a gate, enabling smooth opening and closing, which facilitates unobstructed flow when fully opened. This design minimizes pressure drops and turbulence in the system.

5. Versatility These valves can be used in various applications, including water supply systems, wastewater treatment plants, and chemical processing facilities. Their adaptability to different environments adds to their appeal.

Applications

3% stainless steel gate valves find extensive applications across numerous industries

- Oil and Gas They are used in drilling and refining processes, where reliable control of flow is necessary under extreme conditions. - Chemical Processing In environments with corrosive substances, these valves maintain integrity and prevent leaks and spills.

- Waterworks They play a crucial role in municipal water systems, ensuring efficient flow control and shutdown capabilities.

- Power Generation In power plants, they manage the flow of water, steam, and other fluids crucial to generating electricity.

- Food and Beverage Their sanitary design and corrosion resistance make them ideal for processing plants.

In conclusion, 3% stainless steel gate valves are a vital component in modern industrial applications, known for their strength, durability, and resistance to corrosion. Their ability to withstand extreme conditions makes them a reliable choice for various industries, ultimately contributing to safer and more efficient operations. Whether in energy sectors or water treatment facilities, these valves ensure that operations run smoothly and effectively, providing a crucial interface in the flow control system.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

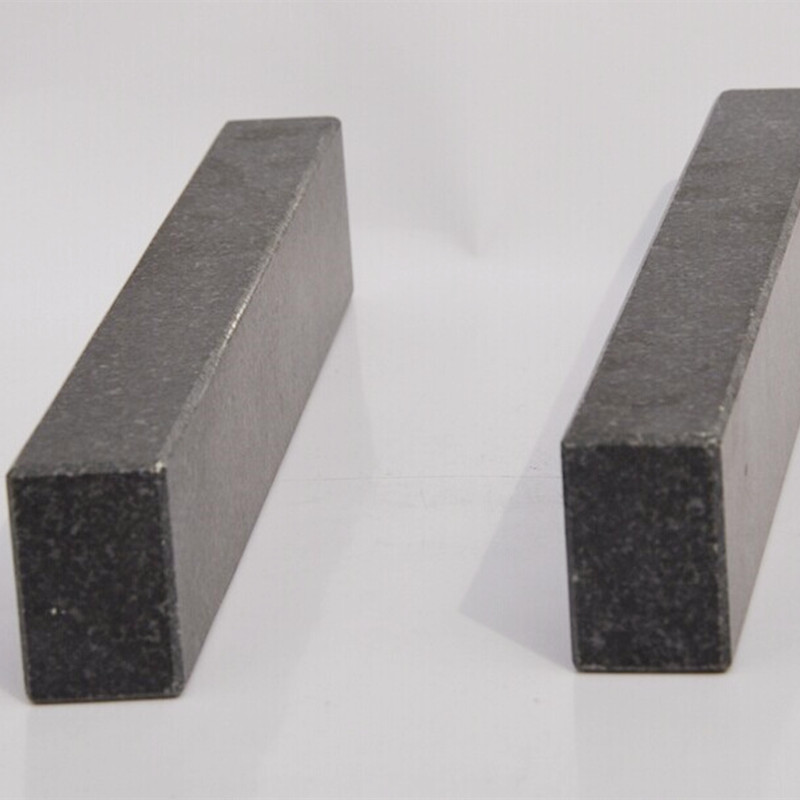

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS