Sep . 29, 2024 03:24 Back to list

Heavy-Duty Fabrication Guidelines for Industrial Applications and Best Practices

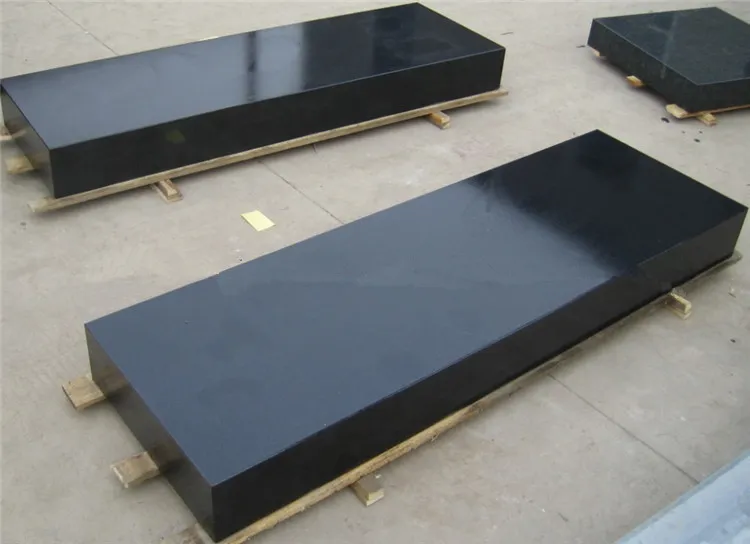

Heavy Duty Fabrication Table An Essential Tool for Industry

In the world of manufacturing and industrial processes, the need for robust and reliable equipment is paramount. One such essential tool that has garnered attention across various sectors is the heavy duty fabrication table. These tables serve as the backbone for welding, assembly, and repair tasks, providing workers with a safe and stable platform to execute intricate projects.

Understanding Heavy Duty Fabrication Tables

Heavy duty fabrication tables are designed to withstand high levels of weight and stress, making them ideal for heavy materials and demanding applications. Constructed from strong materials such as steel or aluminum, these tables are engineered for durability, ensuring they can support heavy loads without bending or warping over time. Their surfaces are often treated with textures or coatings that resist scratching and corrosive substances, enhancing their longevity.

The Importance of Stability and Precision

One of the primary advantages of heavy duty fabrication tables is their ability to offer a stable workspace. In fabrication and welding tasks, precision is crucial. A solid, stable table minimizes vibrations and movements, allowing for more accurate cuts and welds. This stability not only improves the quality of the work produced but also enhances safety, as a steady work environment reduces the risk of accidents caused by slipping or falling materials.

Versatility Across Industries

heavy duty fabrication table

The versatility of heavy duty fabrication tables makes them suitable for various industries, including automotive, aerospace, construction, and metalworking. In each of these sectors, the demands may vary, but the underlying requirement for a dependable workspace remains constant. For instance, in metal fabrication shops, these tables can be used for assembling parts for machinery or customizing items, while in the construction industry, they can serve as a platform for building large structures or components.

Customization and Features

Many manufacturers offer customization options for heavy duty fabrication tables, allowing businesses to adapt the equipment to their specific needs. Features such as adjustable heights, modular designs, and integrated tool storage can enhance usability. Additionally, some tables come equipped with clamping systems, allowing workers to secure materials in place during fabrication. These enhancements contribute to efficiency, as workers can easily access tools and materials without unnecessary downtime.

The Economic Benefits

Investing in heavy duty fabrication tables can result in significant cost savings for businesses. The durability of these tables means that they require less frequent replacement compared to standard tables. Moreover, the improved productivity gained from using a stable and efficient workspace can lead to higher output and better quality products, further contributing to a company's bottom line. In environments where time is money, having the right equipment can make all the difference.

Conclusion

In summary, heavy duty fabrication tables are an indispensable asset in various industrial applications. Their ability to provide stability, precision, and versatility makes them an ideal choice for businesses engaged in tasks that require heavy lifting and meticulous work. As industries continue to evolve and grow, the reliance on robust tools like heavy duty fabrication tables will only increase. Investing in high-quality, durable tables not only enhances productivity and safety but also positions companies for long-term success in a competitive market. By prioritizing reliable equipment, businesses can ensure they meet the demands of modern industry while maintaining high standards of workmanship.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS