Jul . 02, 2024 01:30 Back to list

Global Valve 5k An In-Depth Exploration of Innovative Plumbing Solutions

Understanding the Globe Valve and Its Significance in Industrial Applications

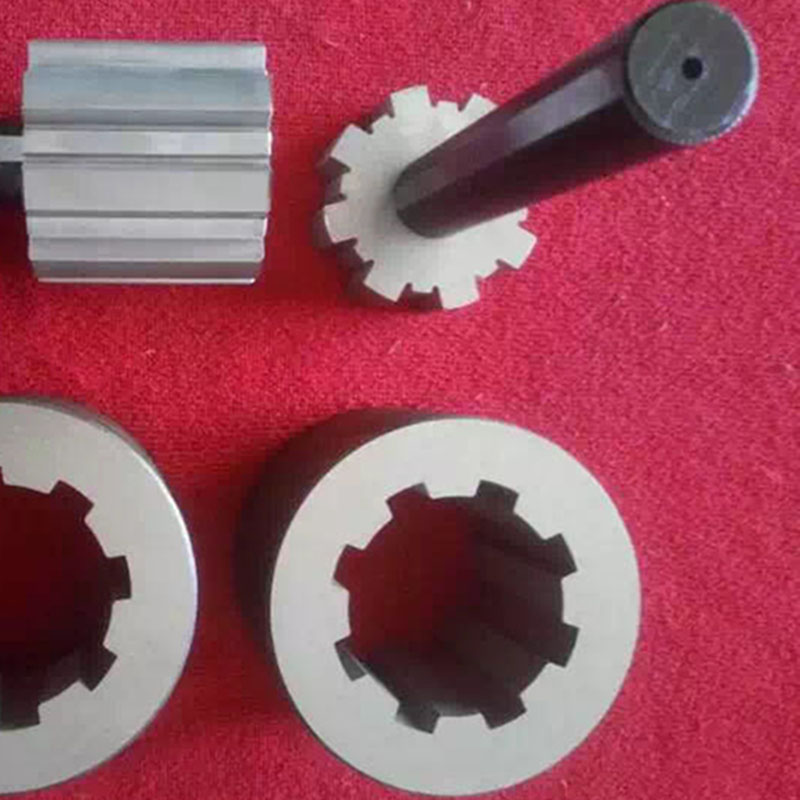

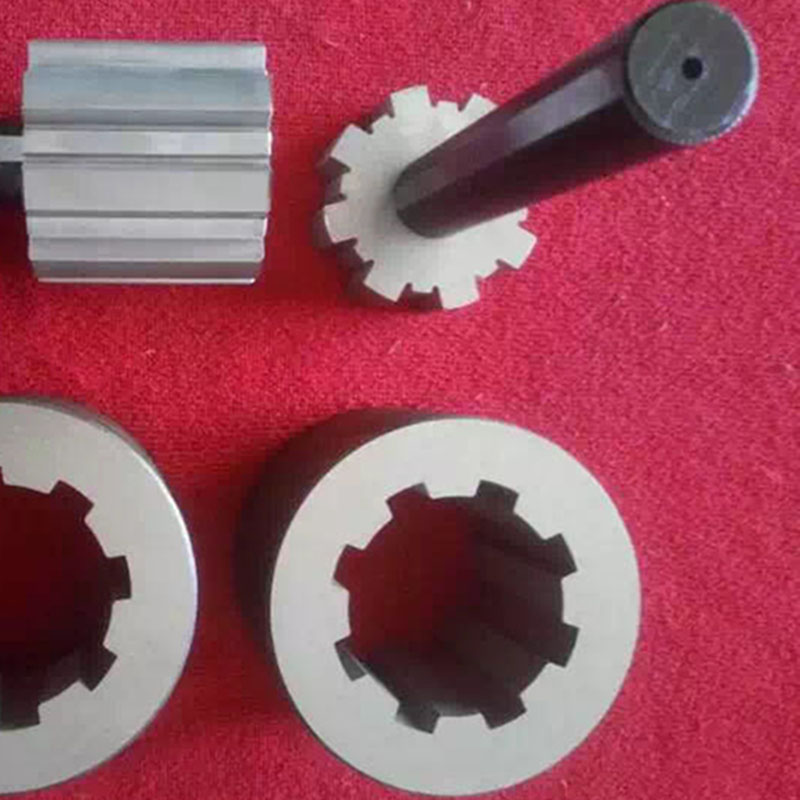

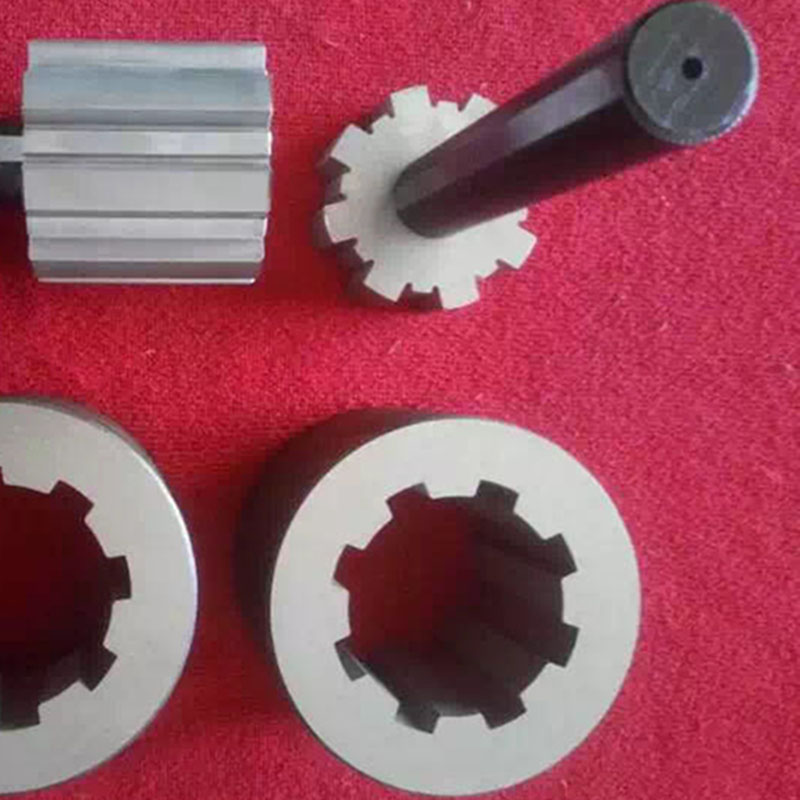

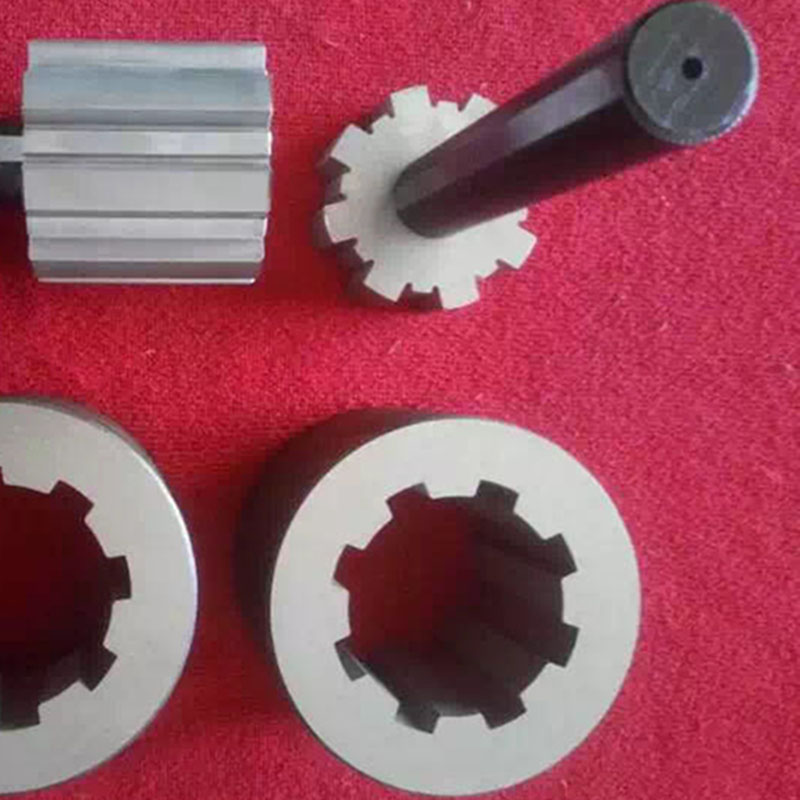

Globe valves, often referred to by their distinctive identifier Globe Valve 5k, are essential components in various industrial piping systems, playing a crucial role in controlling fluid flow. The 5k in the term typically refers to the valve's pressure rating, which signifies that it can withstand a pressure of 5,000 pounds per square inch (PSI), making it suitable for high-pressure applications.

A globe valve gets its name from its distinct globe-like shape, consisting of a body with a spherical division between the inlet and outlet ports. This design allows for precise flow control as the valve disk can be positioned at different angles within the flow path. The valve disk, or plug, can either fully close or partially obstruct the flow, enabling throttling capabilities.

The globe valve's construction is characterized by its simplicity and durability. It comprises a bonnet, body, stem, seat, and disc. The stem connects the handle or actuator to the disc, facilitating the opening and closing action. The seat is where the disc rests when the valve is closed, creating a tight seal. The body houses these components and forms the conduit for the fluid.

In the context of a Globe Valve 5k, the valve is designed to handle high-pressure situations. These valves are commonly found in industries like petrochemicals, power generation, and refineries, where precise flow regulation and high-pressure resistance are paramount. Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted

Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted globe valve 5k.

One of the key advantages of globe valves is their reliability. They offer excellent shutoff capabilities due to the linear motion of the valve plug, ensuring minimal leakage even after numerous cycles. Additionally, their design allows for easy maintenance and repair, as the valve disc and seat can be readily accessed for cleaning or replacement.

However, globe valves are not without limitations. Their inherent design results in a higher pressure drop across the valve compared to other types, such as ball or butterfly valves. This increased friction can lead to energy loss in the system. Despite this, the precision control and robustness of globe valves make them indispensable in specific high-pressure applications.

In conclusion, a Globe Valve 5k is a specialized valve designed to operate effectively in high-pressure environments while offering precise flow control. Its unique design, durability, and maintenance-friendly features make it a go-to choice for engineers in industries where accuracy and resilience are non-negotiable. As technology advances, globe valves continue to evolve, providing innovative solutions to complex fluid control challenges.

globe valve 5k.

One of the key advantages of globe valves is their reliability. They offer excellent shutoff capabilities due to the linear motion of the valve plug, ensuring minimal leakage even after numerous cycles. Additionally, their design allows for easy maintenance and repair, as the valve disc and seat can be readily accessed for cleaning or replacement.

However, globe valves are not without limitations. Their inherent design results in a higher pressure drop across the valve compared to other types, such as ball or butterfly valves. This increased friction can lead to energy loss in the system. Despite this, the precision control and robustness of globe valves make them indispensable in specific high-pressure applications.

In conclusion, a Globe Valve 5k is a specialized valve designed to operate effectively in high-pressure environments while offering precise flow control. Its unique design, durability, and maintenance-friendly features make it a go-to choice for engineers in industries where accuracy and resilience are non-negotiable. As technology advances, globe valves continue to evolve, providing innovative solutions to complex fluid control challenges.

Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted

Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted Their ability to regulate flow without causing significant pressure drops makes them ideal for applications where flow rate needs to be finely adjusted globe valve 5k.

One of the key advantages of globe valves is their reliability. They offer excellent shutoff capabilities due to the linear motion of the valve plug, ensuring minimal leakage even after numerous cycles. Additionally, their design allows for easy maintenance and repair, as the valve disc and seat can be readily accessed for cleaning or replacement.

However, globe valves are not without limitations. Their inherent design results in a higher pressure drop across the valve compared to other types, such as ball or butterfly valves. This increased friction can lead to energy loss in the system. Despite this, the precision control and robustness of globe valves make them indispensable in specific high-pressure applications.

In conclusion, a Globe Valve 5k is a specialized valve designed to operate effectively in high-pressure environments while offering precise flow control. Its unique design, durability, and maintenance-friendly features make it a go-to choice for engineers in industries where accuracy and resilience are non-negotiable. As technology advances, globe valves continue to evolve, providing innovative solutions to complex fluid control challenges.

globe valve 5k.

One of the key advantages of globe valves is their reliability. They offer excellent shutoff capabilities due to the linear motion of the valve plug, ensuring minimal leakage even after numerous cycles. Additionally, their design allows for easy maintenance and repair, as the valve disc and seat can be readily accessed for cleaning or replacement.

However, globe valves are not without limitations. Their inherent design results in a higher pressure drop across the valve compared to other types, such as ball or butterfly valves. This increased friction can lead to energy loss in the system. Despite this, the precision control and robustness of globe valves make them indispensable in specific high-pressure applications.

In conclusion, a Globe Valve 5k is a specialized valve designed to operate effectively in high-pressure environments while offering precise flow control. Its unique design, durability, and maintenance-friendly features make it a go-to choice for engineers in industries where accuracy and resilience are non-negotiable. As technology advances, globe valves continue to evolve, providing innovative solutions to complex fluid control challenges.

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS