Nov . 12, 2024 17:27 Back to list

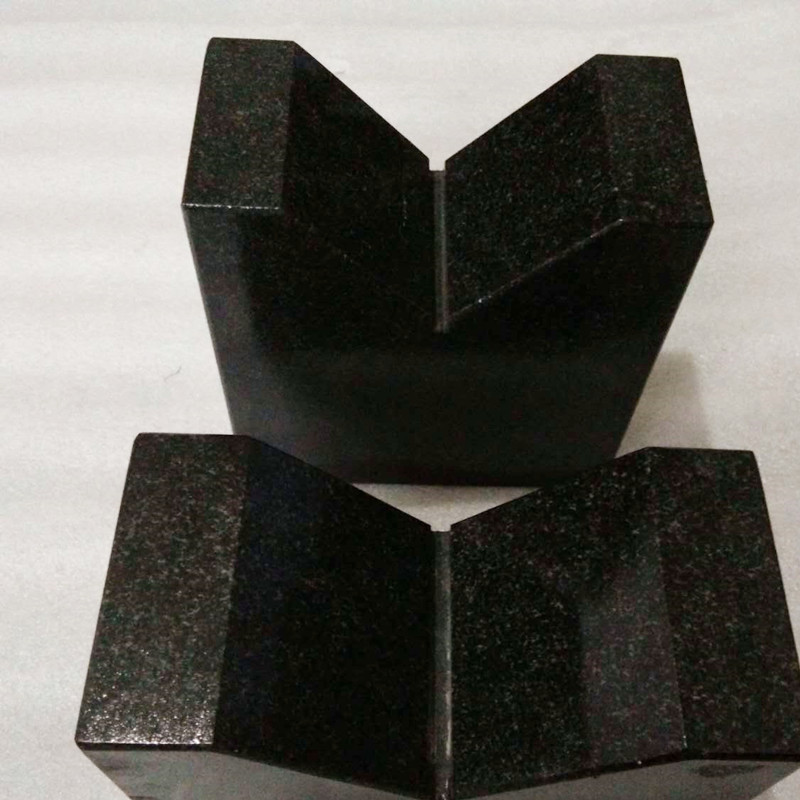

gauge tool

Understanding Gauge Tools Precision Measurement in Engineering

In the realm of engineering and manufacturing, precision is paramount. Whether designing aircraft components, automotive parts, or intricate machinery, the smallest variance can lead to significant degradations in performance and safety. Among the myriad tools used to ensure this precision, gauge tools stand out as vital instruments that help engineers and technicians measure, assess, and validate the dimensions and tolerances of components.

What are Gauge Tools?

Gauge tools, often simply referred to as gauges, are devices used to measure the physical dimensions of an object. They can take various forms and are employed for different types of measurements, including length, width, thickness, and even the internal dimensions of holes and other features. The primary goal of these tools is to ensure that components meet specified tolerances and standards, an essential aspect of quality control in any manufacturing or engineering process.

Types of Gauge Tools

There are several types of gauge tools, each designed for specific measurement tasks. Here are some of the most commonly used categories

1. Calipers Calipers are versatile tools capable of measuring internal and external dimensions as well as depths. They can be analog or digital and provide both metric and imperial readings. Digital calipers are especially popular because they offer precise measurements with easy-to-read displays.

2. Micrometers A micrometer is a tool used for measuring small distances with high accuracy. Typically, they are used for measuring the thickness of materials or the diameter of small objects. Micrometers can read measurements down to the micrometer level (one-millionth of a meter), making them essential in precision engineering.

3. Height Gauges Height gauges are used to measure vertical dimensions accurately. They typically consist of a ruler or gauge attached to a vertical column, which can also be used on a flat surface to measure the height of an object.

gauge tool

4. Thread Gauges These tools are specifically designed to check the pitch and diameter of threads on bolts and screws. They ensure that the threading meets the relevant standards, which is crucial for ensuring mechanical connections function as intended.

5. Feeler Gauges Feeler gauges are a set of thin blades of known thickness used to measure gaps or clearances between parts. They are particularly useful in engines and machinery where precise spacing is crucial for optimal performance.

Applications of Gauge Tools

The application of gauge tools extends across various industries. In the automotive sector, for instance, manufacturers depend on these tools to ensure the precision of engine components, suspension systems, and more. In aerospace engineering, where safety and performance are critical, gauge tools are essential for verifying the integrity of critical parts.

Moreover, in the construction industry, gauge tools help ensure that materials meet building codes and specifications. They are used to measure everything from the thickness of structural steel to the dimensions of doors and windows.

The Importance of Calibration

To maintain accuracy, gauge tools must be regularly calibrated. Calibration involves comparing measurements taken by the gauge against a known standard and adjusting it as necessary. This process is crucial because even the most precise gauge can yield incorrect measurements if it is not properly maintained. Many industries have set guidelines for calibration, ensuring that tools are functioning correctly and providing reliable data.

Conclusion

In conclusion, gauge tools are indispensable assets in the world of engineering and manufacturing. Their ability to deliver precise measurements plays a critical role in ensuring product quality and safety across various industries. As technology advances and demands for precision become even more stringent, the importance of adequately utilizing and maintaining gauge tools will only continue to grow. Understanding the different types of gauges and their applications is fundamental for any engineer or technician dedicated to maintaining the highest standards of accuracy and quality in their work. With the right tools in hand, professionals can confidently tackle the challenges of modern engineering and manufacturing, driving innovation and excellence in every project.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS