Sep . 30, 2024 03:14 Back to list

Understanding Gauge Pin Class and Its Importance in Measurement and Tolerances

Understanding Gauge Pin Classes A Comprehensive Overview

Gauge pins play an essential role in the field of manufacturing and quality control. They are precision tools used to check the size, form, and location of holes in a workpiece. The accuracy of these measurements is critical in ensuring that components fit together correctly in assembly processes. One important aspect of gauge pins is their classification, which is often referred to as gauge pin class. In this article, we will explore the various classes of gauge pins, their applications, and the significance of their precise dimensions in industrial processes.

What are Gauge Pins?

Gauge pins are cylindrical rods made of high-quality steel or carbide, designed to fit smoothly into predetermined holes. Their primary function is to serve as a go/no-go gauge, providing a quick and reliable method for measuring the specifications of holes. By inserting a gauge pin into a hole, operators can immediately determine whether the hole meets the specified tolerances. If the pin fits perfectly, the hole is considered to be within specification (go). Conversely, if the pin does not fit, it indicates an out-of-tolerance condition (no-go).

Classification of Gauge Pins

Gauge pins are classified into different classes based on their manufacturing tolerances and intended applications. The classification typically includes

1. Go Pins These pins are designed to fit into the hole. They represent the maximum material condition of the hole, meaning it is the largest size that is acceptable. If a go pin fits, the hole is within acceptable tolerances.

2. No-Go Pins These pins are intended to not fit into the hole. They represent the minimum material condition. If a no-go pin fits, the hole is deemed too large and out of tolerance.

3. Intermediate Pins These pins have dimensions between the go and no-go pins. They can be used for finer tolerances and more strict measurements when required.

Tolerance and Precision in Gauge Pin Classes

The accuracy of gauge pins is defined by their tolerance classes, often specified according to the ISO or ANSI standards. These standards outline the acceptable limits of deviation for each class of gauge pin. For example

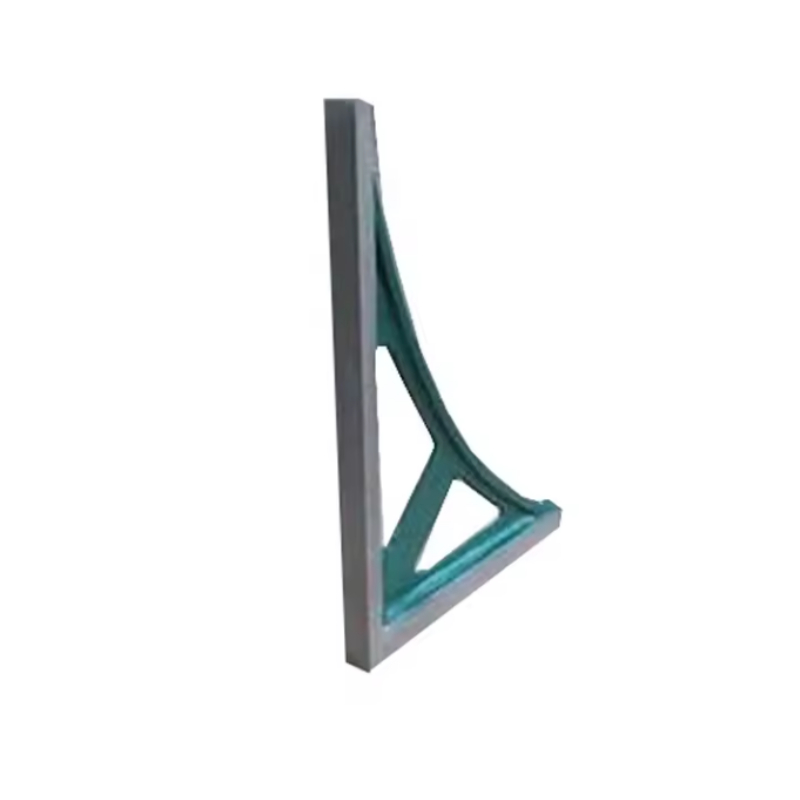

gauge pin class

- Class 0 This class represents the highest tolerance, suitable for applications where precision is critical. It allows for minimal deviation and is often used in aerospace and automotive industries where safety is paramount.

- Class 1 This class offers a slightly broader tolerance than Class 0 but is still suitable for precision engineering applications.

- Class 2 and Class 3 These classes are used for less critical applications where some degree of deviation can be tolerated. They are commonly used in general manufacturing processes.

Applications of Gauge Pin Classes

The precise measurement capability of gauge pins makes them invaluable in a variety of industries, such as

- Automotive Ensuring that the components fit together correctly, which is essential for safety and performance.

- Aerospace High-stakes environments demand impeccable dimensions; gauge pins are critical in ensuring that components meet strict safety regulations.

- Manufacturing Used in the inspection of machined parts to guarantee they meet specific tolerances.

- Medical Equipment Precision is vital in the manufacturing of medical devices; gauge pins help in maintaining stringent quality control.

Conclusion

Understanding the different classes of gauge pins is crucial for professionals in manufacturing, quality control, and engineering. Each class serves a unique purpose, catering to various levels of precision and application requirements. The importance of using the correct gauge pin cannot be overstated, as it directly impacts the quality and reliability of the final product. Proper selection and application of gauge pins contribute to efficiency in production processes and, ultimately, customer satisfaction. Whether in the automotive sector, aerospace, or general manufacturing, gauge pins remain a cornerstone of quality assurance.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS