Dec . 12, 2024 11:21 Back to list

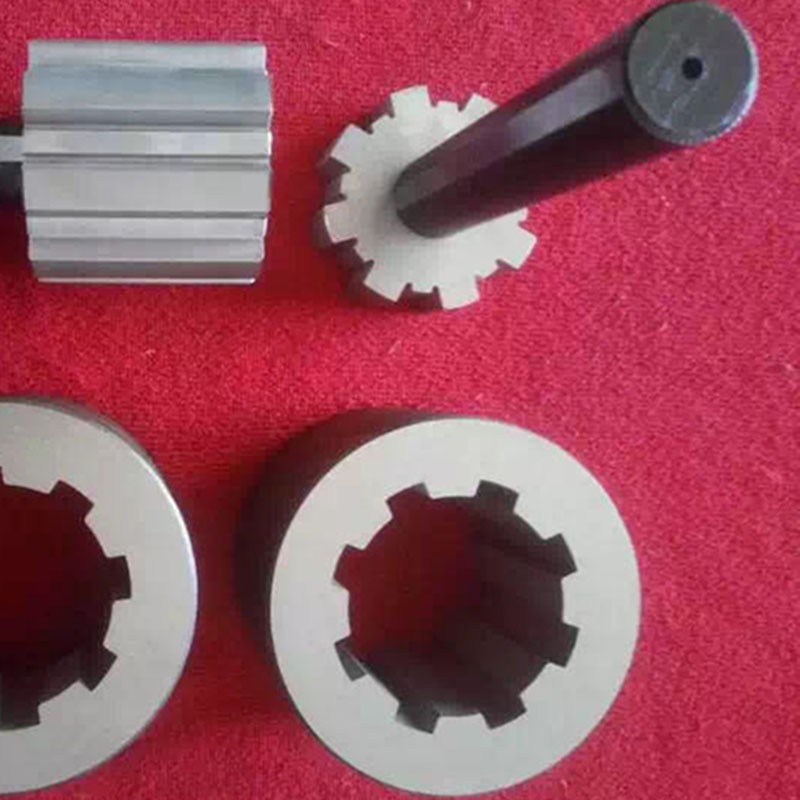

gauge c

Understanding Gauge %C A Key Tool in Performance Measurement

In the realm of performance measurement and quality control, numerous metrics and indicators are utilized to assess a process's efficiency and effectiveness. One such crucial metric is Gauge %C, a valuable tool that offers insights into the precision and reliability of measuring instruments. This article provides an overview of Gauge %C, its significance, calculation methods, and applications across various industries.

What is Gauge %C?

Gauge %C is a statistical measure that indicates the capability of a measurement system. It assesses the proportion of the total variability in a process that can be attributed to the measurement system itself. In simple terms, Gauge %C helps determine how much of the observed variation in a product or process outcome can be deemed as measurement error rather than actual variation inherent to the process.

The Gauge %C value is essential for organizations relying on measurements for quality control, as it directly impacts decision-making, process improvements, and product quality.

Importance of Gauge %C

1. Quality Assurance Ensuring the quality of products and processes is paramount in industries such as manufacturing, healthcare, and aerospace. A high Gauge %C indicates that the measurement system is reliable, leading to accurate data that can inform quality assurance measures.

2. Process Improvement Organizations strive for continuous improvement. Recognizing the variability introduced by measuring instruments allows teams to isolate and reduce sources of error, driving overall process optimization.

3. Regulatory Compliance Many industries are subject to strict regulatory standards. Proper measurement practices are crucial for compliance, and Gauge %C serves as a benchmark for meeting these requirements. Low Gauge %C values can signify potential non-compliance, prompting immediate corrective actions.

Calculating Gauge %C

gauge c

Gauge %C is calculated using the following formula

\[ \text{Gauge %C} = \left( \frac{\text{Total Variation attributable to the Gauge}}{\text{Total Variation in the Process}} \right) \times 100 \]

To break it down further, the total variation can be derived from the sum of the part-to-part variation (the variability in the actual product or process) and the gauge variation (the variability attributed to the measurement system). The goal is to have a low Gauge %C value indicating that the measurement system contributes minimally to total process variation.

Applications of Gauge %C

1. Manufacturing In manufacturing settings, precise measurements are critical for quality control. Gauge %C is employed to evaluate the reliability of measuring tools—such as calipers, gauges, and scales—ensuring that products meet specifications consistently.

2. Healthcare In clinical laboratories, accurate measurement is vital for patient safety. Gauge %C helps assess the reliability of diagnostic instruments, influencing treatment decisions and maintaining high medical standards.

3. Aerospace The aerospace industry demands rigorous adherence to safety standards. Gauge %C is used to evaluate testing instruments to ensure that every aspect of aerospace production meets stringent safety and performance requirements.

Conclusion

In conclusion, Gauge %C is an indispensable metric for organizations seeking to enhance their measurement practices and overall quality management systems. By understanding and applying this tool, businesses can mitigate risks associated with measurement errors, improve product quality, and support continuous improvement initiatives. As industries evolve and become increasingly data-driven, the importance of accurate and reliable measurements continues to grow. Incorporating Gauge %C into regular performance assessment routines will undoubtedly yield substantial benefits in operational excellence and customer satisfaction.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS