Dec . 18, 2024 07:10 Back to list

Cost Analysis of Gate Valve Pricing in Today's Market

Understanding Gate Valve Prices Factors and Market Trends

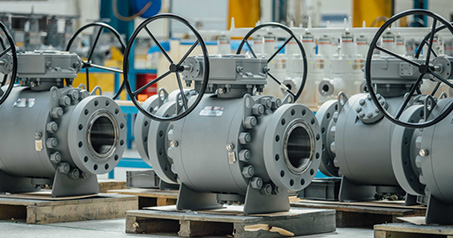

When it comes to industrial applications, gate valves are essential components used extensively in various industries, including oil and gas, water supply, and manufacturing. They provide reliable flow control for liquids and gases, making their pricing an important aspect to consider for engineers and procurement professionals alike. In this article, we will explore the factors that affect gate valve prices, recent market trends, and how to approach purchasing decisions.

What is a Gate Valve?

Before diving into pricing, let’s clarify what a gate valve is. A gate valve is designed to start or stop the flow of fluid through a pipeline. Unlike other types of valves, such as ball or globe valves, gate valves are primarily used for on-off control and are not intended for throttling. The valve comprises a solid wedge or gate that moves up and down, allowing or restricting fluid flow. They can be made from various materials, including cast iron, stainless steel, and bronze, each impacting their price.

Factors Influencing Gate Valve Prices

1. Material Type The material used in manufacturing the gate valve significantly affects its cost. For instance, stainless steel valves tend to be more expensive than those made from cast iron due to their corrosion resistance and strength properties, which are essential for high-pressure and high-temperature applications.

2. Size and Specifications Gate valves come in various sizes, from small-inch valves used in residential plumbing to large industrial valves capable of handling substantial volumes. Larger valves with higher pressure ratings often come at a premium. Specialized valves, such as those with unique dimensions or design specifications, are also likely to be priced higher due to custom manufacturing processes.

3. Manufacturing Processes The method used to manufacture the valve can impact its cost. Valves that require precise machining and quality control, like forged valves, tend to be more expensive than those made through casting processes. Additionally, valves with advanced features, such as automated actuation systems, will further increase the price.

4. Brand and Certification Just like any other product, the brand reputation significantly influences gate valve pricing. Established manufacturers with a track record of quality and reliability often command higher prices. Furthermore, certifications (like API, ANSI, or ISO) that indicate adherence to industry standards contribute to trust and can raise the price as well.

5. Market Demand and Supply Chain The economic landscape, including demand and supply dynamics, heavily influences the pricing of gate valves. Fluctuations in material costs, production capacity, and market demand can alter prices substantially. For instance, if there’s a surge in demand for gate valves during a construction boom, prices may rise accordingly.

gate valve price

Recent Market Trends

The global gate valve market has been witnessing notable trends. An increase in infrastructure projects, particularly in developing countries, has led to rising demand for gate valves. Additionally, advancements in manufacturing technology have helped produce more cost-effective solutions without compromising quality.

Sustainability has become an essential consideration, leading to innovations in materials and designs that enhance energy efficiency. Smart valves integrated with IoT (Internet of Things) technology are now becoming more prevalent, permitting remote monitoring and control, which, while initially more expensive, can offer long-term cost savings.

Making Informed Purchasing Decisions

When considering the purchase of gate valves, it is essential to balance quality, cost, and operational needs. Here are a few recommendations

- Assess the Application Understand the specific requirements of your application — the type of fluid, operating pressure, temperature, and space constraints. This clarity will help you choose the right valve. - Get Multiple Quotes Always solicit quotes from multiple suppliers. This practice not only gives insight into current market prices but also helps in understanding the range of options available.

- Consider Total Cost of Ownership (TCO) While upfront costs are crucial, consider maintenance, lifespan, and efficiency to get a complete picture of the investment.

- Consult Experts Engage with industry experts or consultants who can provide insights and help navigate complex purchasing decisions.

Conclusion

Gate valve prices are influenced by a myriad of factors, from material and size to market dynamics. Understanding these elements will enable stakeholders to make informed decisions that align with their operational goals while ensuring cost-effectiveness. As industries continue to evolve, staying abreast of market trends will further facilitate strategic purchasing and risk management in valve procurement.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS