Dec . 02, 2024 00:56 Back to list

gate valve on off

Understanding Gate Valves The On/Off Control Mechanism

Gate valves are fundamental components in various industrial applications, particularly in the oil and gas, water treatment, and chemical processing sectors. Their primary function is to control the flow of fluids by either fully opening or fully closing the passage. This ability to provide an on or off control mechanism makes gate valves an essential choice for many pipeline systems.

What is a Gate Valve?

A gate valve is a type of valve that uses a sliding gate to obstruct or permit fluid flow. They are generally used in situations where the flow needs to be either fully on or fully off, rather than in a throttling position. When the gate valve is fully open, the fluid flows freely through the valve with minimal pressure loss. Conversely, when fully closed, the gate effectively blocks the flow, preventing any fluid from passing through.

Gate valves are typically designed with a variety of materials, including metal, rubber, and plastic, depending on the application and the characteristics of the fluid being controlled. The choice of material affects the valve's durability, resistance to corrosion, and ability to handle pressure.

Design and Operation

The design of a gate valve typically includes a body, a gate, a stem, and a handwheel or actuator for operation. The gate can be either wedge-shaped or parallel-sliding, and this design influences the valve's performance and suitability for different applications. Wedge gate valves are more commonly used, as they provide a tighter seal when closed, which reduces the risk of leakage.

When operated, turning the handwheel raises or lowers the gate. In its fully open position, the gate is lifted out of the flow path, minimizing resistance. However, as the gate descends, it creates an obstruction that prevents fluid flow, effectively turning the valve off. This simple operation is what makes gate valves so prominent in controlling flow in pipelines.

Advantages of Gate Valves

One of the main advantages of gate valves is their ability to provide a straight-through flow path. Unlike other types of valves, such as globe valves, the design of a gate valve ensures that there is minimal pressure drop during operation. This feature is particularly crucial in systems where maintaining pressure is essential.

gate valve on off

Additionally, gate valves have a robust design that allows them to withstand high pressures and temperatures, making them suitable for heavy-duty applications. Their durability and reliability ensure a long service life, contributing to lower maintenance costs over time.

Disadvantages and Limitations

Despite their many advantages, gate valves also have certain limitations. One significant downside is that gate valves are not well-suited for throttling or flow regulation. Their design is optimized for either fully open or fully closed positions, making them ineffective for applications that require fine control over fluid flow.

Moreover, because the gate must be fully raised or lowered, the operation of a gate valve can be slower compared to other designs, such as ball valves. This can be a disadvantage in systems where quick shut-off is necessary, particularly in emergency situations.

Applications of Gate Valves

Gate valves are widely used in various sectors. In the water supply industry, they help in controlling the flow of water in pipelines, enabling operators to manage supply effectively. In the oil and gas industry, they are used to isolate sections of the pipeline for maintenance or emergency response.

Furthermore, gate valves play a crucial role in chemical processing plants, where they control the flow of corrosive fluids. Their ability to provide a tight seal is essential for preventing leakage and ensuring safety in these environments.

Conclusion

In summary, gate valves serve a vital purpose in numerous industrial applications. Their straightforward on/off functionality, combined with their durability and reliability, makes them an attractive option for many pipeline systems. Understanding their design, advantages, and limitations is key for engineers and operators to utilize them effectively. Whether managing water supply, oil and gas distribution, or chemical processing, the gate valve remains an indispensable tool in fluid control technology.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

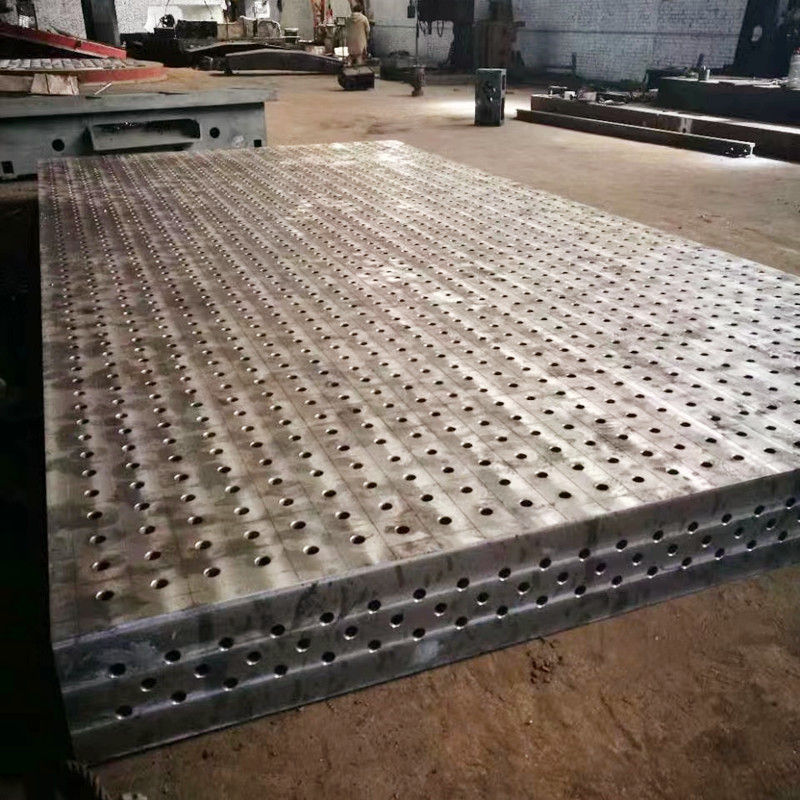

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS