Nov . 16, 2024 05:16 Back to list

flow control valve types

Understanding Flow Control Valve Types

Flow control valves play a crucial role in various industrial applications, managing the flow rate of liquid or gas within a system. These valves are essential for maintaining optimal operating conditions, protecting equipment, and ensuring efficient processes. Understanding the different types of flow control valves is key for engineers and technicians who design and maintain systems in industries like manufacturing, oil and gas, and water treatment. This article will explore the various types of flow control valves, their mechanisms, advantages, and applications.

1. Globe Valves

Globe valves are one of the most common types of flow control valves. They feature a spherical body with an internal baffle that creates a specific flow path. This design allows for good throttling capabilities, making them ideal for situations where flow regulation is important. Globe valves are often used in steam, water, and other media flows, allowing precise control of the flow rate. Their disadvantage is that they can cause pressure drops due to their restrictive design.

2. Ball Valves

Ball valves consist of a spherical disc that controls the flow through it. When the ball is rotated, it either allows or completely stops the flow. Ball valves are favored for their durability and ability to provide tight sealing, making them perfect for on/off control applications. They are also available in various materials, making them suitable for a wide range of fluids, including corrosive substances. However, ball valves are not ideal for flow regulation, as they tend to either fully open or close without any throttling option.

Butterfly valves are designed with a rotating disc that is positioned in the center of the pipe. This valve is widely used for regulating flow because it can quickly open and close, offering efficient flow control. The compact design of butterfly valves makes them suitable for large diameter pipes, and they are commonly used in water supply and wastewater treatment facilities. Their primary disadvantage is that they may not provide as fine a flow control as globe valves.

flow control valve types

4. Check Valves

Check valves are designed to prevent backflow in a system, ensuring that the flow runs in one direction. While they don't directly control flow rate, they are critical for maintaining system integrity and protecting equipment from damage caused by reverse flow. There are different types of check valves, including swing check, lift check, and diaphragm check valves, each suited for specific applications.

5. Needle Valves

Needle valves are designed for precise flow regulation and are often used in low flow applications. Their long, tapered seat allows for fine adjustments to the flow rate, making them ideal for applications in laboratories or for measuring small quantities of liquids or gases. Due to their design, needle valves can experience pressure drops at higher flow rates, so they are not typically used in applications requiring high flow.

6. Electromagnetic Flow Control Valves

These modern valves are electronically controlled, allowing for automated and precise flow regulation. They are ideal for systems where flow needs to be adjusted dynamically based on real-time data. Applications include HVAC systems, chemical processing, and food and beverage industries. The main advantage of electromagnetic flow control valves is their ability to integrate with modern control systems for enhanced efficiency.

Conclusion

In summary, flow control valves are vital components in many industrial systems, each type offering unique advantages and suitable applications. Understanding the differences among globe, ball, butterfly, check, needle, and electromagnetic valves helps engineers and technicians select the right valve for their specific needs. By carefully choosing and implementing the appropriate flow control valve, industries can achieve improved efficiency, enhanced safety, and optimized performance in their operations.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

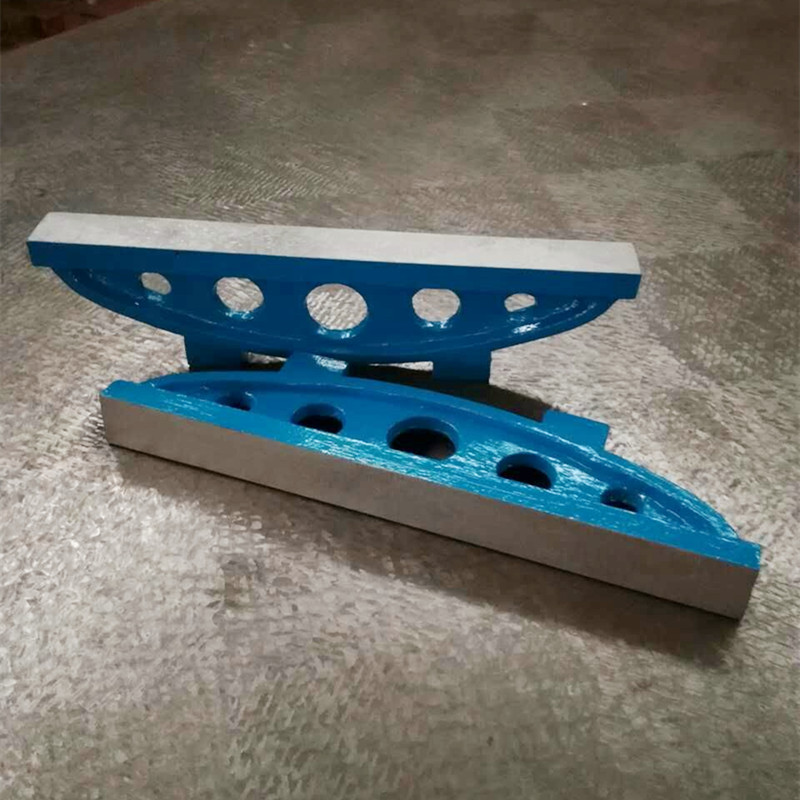

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS