Jul . 26, 2024 09:38 Back to list

Exploring the Importance of Gauge Measurement in Precision Ring Manufacturing Techniques

Understanding Gauge Meant Rings Precision in Measurement

In various fields such as engineering, manufacturing, and even jewelry design, precise measurements are crucial. One instrument that embodies this accuracy is the gauge meant ring. Often used in conjunction with other measuring tools, the gauge meant ring plays an important role in ensuring that measurements are not just close, but exact.

What is a Gauge Meant Ring?

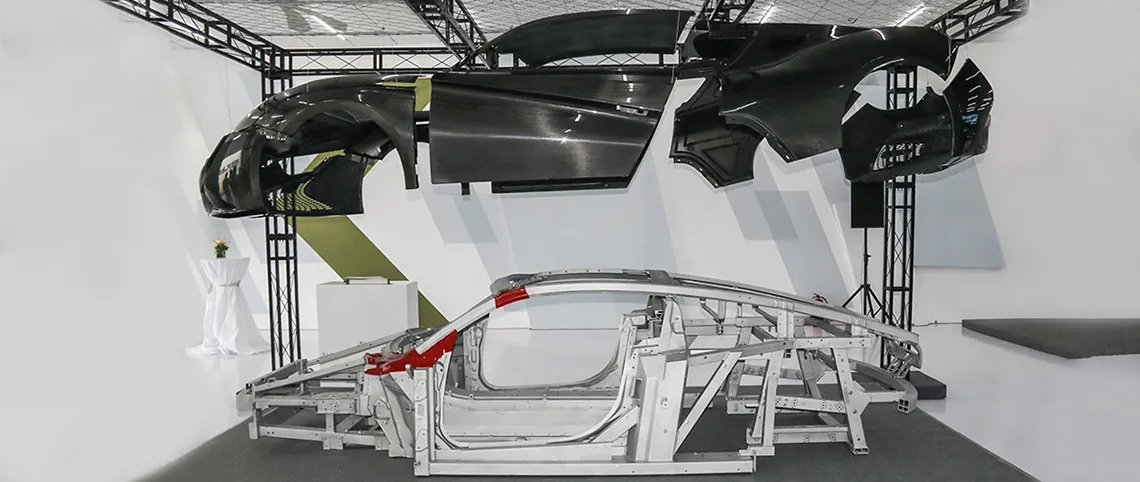

A gauge meant ring is a type of ring designed to measure or check the size of a hole or the dimensions of an object precisely. It is typically made from durable materials such as steel or other robust alloys that can withstand wear and tear, ensuring longevity and consistent reliability. The design of the ring allows it to fit snugly over a specific sized object, thereby offering a clear indication of the size. This feature is particularly useful in fields where precision is paramount, such as aerospace, automotive, and various engineering applications.

The Importance of Precision

In industries where even a fraction of a millimeter can lead to significant errors, the need for precision cannot be overstated. For instance, in the automotive sector, the fitting of parts and components must be exact to ensure safety and functionality. A gauge meant ring helps in achieving just that, allowing engineers to verify that each part meets the specified tolerances before assembly. Similarly, in the aerospace industry, where the margins for error are exceedingly slim, the use of gauge rings assures that components are designed and manufactured to exact specifications.

How Gauge Meant Rings are Used

gauge meant ring

Using a gauge meant ring is straightforward. The operator selects the ring that corresponds to the desired measurement and places it onto the object. If the ring fits perfectly without any slack or resistance, this indicates that the dimensions are accurate. If the ring fails to fit, it signals that the object may be too large or too small, prompting further adjustments or checks.

This simplicity provides an efficient way to conduct measurements quickly on the shop floor or during quality assurance processes. It eliminates guesswork and saves time, which is invaluable in high-demand industries that thrive on productivity.

Applications Beyond Industry

Interestingly, the applications of gauge meant rings extend beyond industrial uses. In jewelry making, for example, gauge meant rings serve as a tool for assessing ring sizes accurately. Jewelers can use these rings to ensure that rings are crafted to fit their clients perfectly. This is particularly important in custom jewelry design, where comfort and fit are essential to customer satisfaction.

Moreover, gauge meant rings find use in crafting tools and equipment in various crafts and trades, demonstrating their versatility as a reliable measurement tool across different fields.

Conclusion

In conclusion, gauge meant rings represent a perfect blend of simplicity and functionality in measurement. They are essential tools that ensure precision, reliability, and ultimately, quality in the manufacturing process across various industries. As the pursuit of accuracy continues to dominate technological advancements, tools like gauge meant rings will undoubtedly remain invaluable in maintaining the high standards needed for successful operation and innovation in today’s demanding environment. Whether in engineering, manufacturing, or jewelry design, the significance of these seemingly simple tools cannot be overlooked.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS