Aug . 12, 2024 04:36 Back to list

Exploring the Functionality and Applications of 1 Way Check Valves in Fluid Systems

Understanding the 1% Way Check Valve Its Importance and Applications

In the world of fluid dynamics and hydraulic systems, the check valve plays a crucial role in ensuring that fluids flow in the desired direction while preventing backflow. Among the various types of check valves, the 1% way check valve offers unique advantages and specific applications in industrial settings. This article delves into the features, benefits, and applications of the 1% way check valve, showcasing its significance in modern engineering.

What is a 1% Way Check Valve?

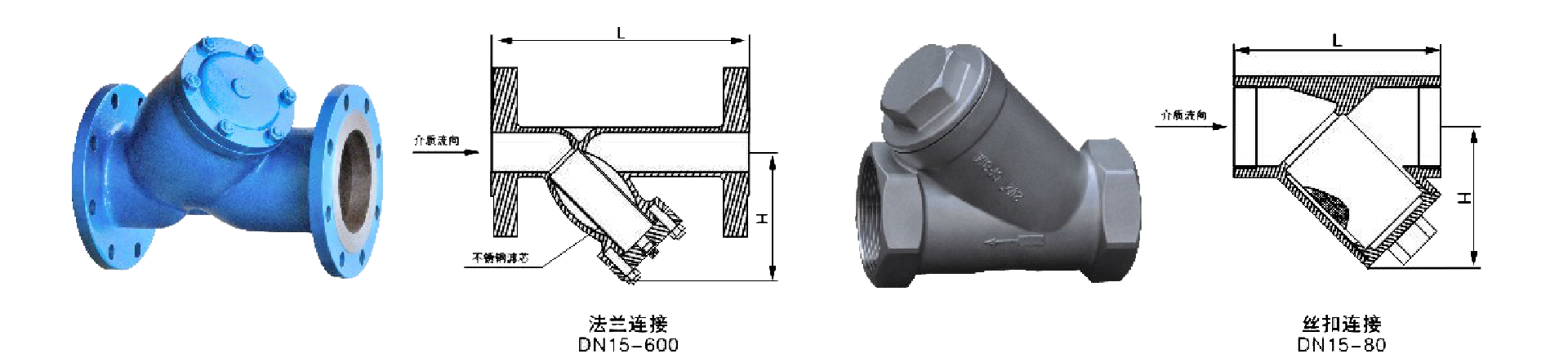

A 1% way check valve, as the name suggests, allows fluid to flow predominantly in one direction—approximately 99% efficiency in preventing reverse flow. This design is engineered for applications where a near-total prevention of backflow is vital for system integrity and operational efficiency. The valve achieves this by utilizing a lightweight disc or ball that responds to pressure differences, ensuring that any reverse flow is effectively mitigated.

Key Features and Advantages

1. High Backflow Prevention The primary advantage of a 1% way check valve is its exceptional ability to prevent backflow. This characteristic is particularly important in systems where back pressure can lead to contamination or system failure.

2. Simplicity and Reliability Designed with minimal moving parts, the 1% way check valve is not only easy to install but also low in maintenance. Its straightforward design contributes to its reliability in a variety of operational environments.

3. Versatility in Applications These valves can be employed in numerous industries including water treatment, oil and gas, chemical processing, and HVAC systems. Their ability to handle different types of fluids—both liquids and gases—makes them indispensable in many processes.

1 way check valve

4. Cost-Effective Solution Given their durability and effectiveness, 1% way check valves can represent a cost-effective solution for businesses aiming to improve system reliability and reduce downtime related to maintenance or repairs.

Applications of 1% Way Check Valves

1. Water and Wastewater Treatment In water treatment facilities, these valves are utilized to prevent backflow, ensuring that clean water remains uncontaminated. They are equally crucial in wastewater treatment, helping to manage the flow of effluents without allowing them to revert back into clean water sources.

2. Oil and Gas Industry In the extraction and transportation of oil and gas, 1% way check valves are essential to prevent the backflow of materials which could cause leaks or reduce system pressure. Their robust design withstands the harsh conditions typical of this industry.

3. Chemical Processing In chemical plants, maintaining the correct flow of reactants is critical. The 1% way check valve plays a significant role in ensuring that chemicals flow to where they are needed without the risk of backflow, which could lead to hazardous situations.

4. HVAC Systems In heating, ventilation, and air conditioning applications, these valves help maintain airflow and protect components from pressure fluctuations, contributing to overall system efficiency.

Conclusion

The 1% way check valve is a vital component in numerous industrial applications where fluid direction must be carefully controlled. Its design not only enhances system performance but also provides reliable backflow prevention. By ensuring that fluids move only in the desired direction, the 1% way check valve safeguards the integrity of operations across a wide range of industries. As technology advances and industries evolve, the importance of such efficient mechanisms will only continue to grow, making check valves indispensable in our modern infrastructure.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS