Jul . 26, 2024 09:45 Back to list

Exploring the Features and Applications of a 10% Knife Gate Valve for Efficient Flow Control

Understanding the 10% Knife Gate Valve Function, Benefits, and Applications

The knife gate valve has become an essential component in various industrial applications, particularly in the management of bulk materials and fluids. Among its various models, the 10% knife gate valve stands out, providing unique functionality in applications requiring controlled flow and isolation. This article delves into the characteristics, benefits, and applications of the 10% knife gate valve.

What is a Knife Gate Valve?

A knife gate valve is a type of valve that uses a sharp-edged blade, or knife, to cut through materials, making it ideal for handling slurries, thick liquids, and solid materials. The primary function of the knife gate valve is to provide a tight seal and reliable isolation of the flow path, making it an invaluable tool in various industries, including mining, wastewater treatment, and pulp and paper production.

Characteristics of the 10% Knife Gate Valve

The 10% knife gate valve typically refers to the valve's design parameters, indicating a seat leakage rate of 10%, which is a crucial measurement of the valve's performance. This level of leakage is crucial for systems where slight seepage is permissible without compromising overall operational efficiency.

1. Durability The structural design of the 10% knife gate valve incorporates robust materials that withstand wear and tear from abrasive materials. The blade is designed to operate efficiently over time, reducing the need for frequent replacements.

2. Flow Control These valves provide excellent on/off control capabilities, facilitating the management of flow rates in a variety of processes. The knife gate design enables smooth operation even in high-pressure environments.

3. Simplicity of Design Unlike more complex valve types, the simplicity of the knife gate valve allows for easier installation and maintenance. Fewer parts mean reduced opportunities for mechanical failure and downtime.

4. Adaptability The 10% knife gate valve can often be customized to meet specific process requirements. This adaptability makes it suitable for numerous applications across different industries.

Benefits of Using a 10% Knife Gate Valve

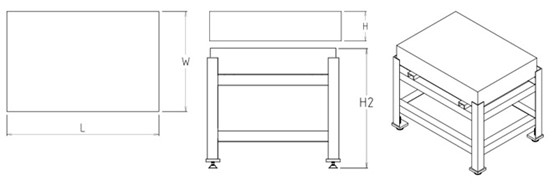

10 knife gate valve

The use of a 10% knife gate valve provides several significant advantages

- Cost-Effectiveness Due to its simplistic design and durability, the 10% knife gate valve often proves to be a cost-effective option over time. Reduced maintenance costs and extended service life contribute to overall savings.

- Efficiency in Handling Solid Materials This valve type excels in environments where the flow consists of solid particles or viscous substances. It can handle varying consistencies without loss of performance.

- Minimal Leakage With a leakage rate of 10%, this valve is capable of offering a balance between flow control and minimal seepage, appropriate for processes that don’t require absolute zero leakage.

Applications in Various Industries

The versatility of the 10% knife gate valve allows it to be employed across a wide array of industries

- Mining In the mining industry, the valve is often used to manage the flow of slurries and other materials, ensuring efficient processing of mined resources.

- Wastewater Treatment These valves provide critical isolation control in treatment plants, aiding in the reliable management of waste materials.

- Pulp and Paper In the pulp and paper industry, knife gate valves are essential for managing the flow of pulp and slurry, contributing to operational efficiency.

Conclusion

The 10% knife gate valve represents a vital component in industrial applications where effective flow control, durability, and cost-efficiency are necessary. Its unique design offers remarkable handling of solid and viscous materials, ensuring that industries can maintain efficient operations. As technology advances, the knife gate valve continues to evolve, ensuring that it meets the ever-changing demands of production processes across various sectors.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS