Aug . 01, 2024 02:22 Back to list

Exploring the Benefits of Using V Blocks in Precision Machining Applications and Techniques

V Blocks for Machining Essential Tools for Precision Engineering

In the world of machining and precision engineering, the importance of accurate measurements and reliable tooling cannot be overstated. One such essential tool that has stood the test of time is the V-block. Designed primarily for holding and stabilizing cylindrical objects during machining processes, V-blocks have become indispensable in many workshops and manufacturing settings.

A V-block is typically a block of metal or other durable material with a V-shaped groove cut into its surface. This unique design allows it to accommodate round workpieces securely, making it easier for machinists to drill, mill, grind, or perform other operations with great precision. The V-shape ensures that the workpiece is firmly held in place, reducing the risk of movement that could lead to inaccuracies in the machining process.

V Blocks for Machining Essential Tools for Precision Engineering

Machinists often use V-blocks in conjunction with clamps or vises to achieve even greater stability. When a V-block is mounted on a workbench or machine table, it provides a solid foundation that enhances the overall workholding capabilities. This combination allows for greater freedom in manipulating the workpiece during machining operations, which is critical when working with intricate designs or tight tolerances.

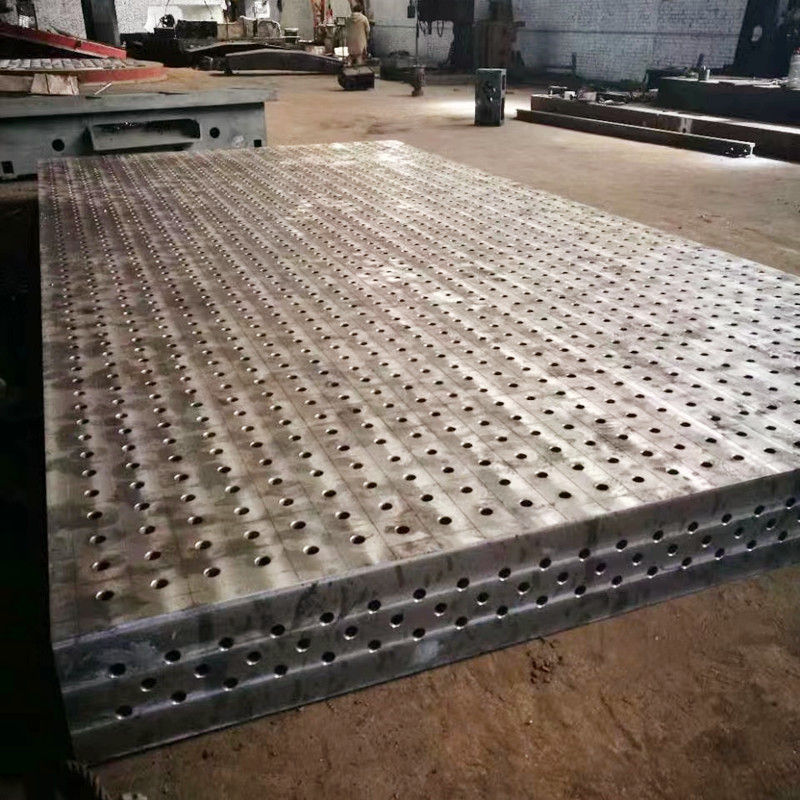

v blocks for machining

Beyond their mechanical advantages, V-blocks are also designed with durability and precision in mind. High-quality V-blocks are typically made from hardened steel or cast iron, ensuring they can withstand the rigors of machining without deforming or wearing out. Additionally, many manufacturers provide V-blocks that have been precision-ground to ensure that the grooves are uniform and accurately sized, further ensuring the reliability of the machining process.

In terms of maintenance, V-blocks require minimal upkeep. Regular inspection for signs of wear, scratches, or deformation will ensure that they remain effective tools in the workshop. Cleaning them after use—removing any chips, oils, or debris—will prolong their lifespan and maintain their accuracy.

For those looking to invest in V-blocks, it is essential to consider the various sizes, shapes, and features available in the market. While standard V-blocks are widely used, there are also specialized variants designed for specific applications, such as magnetic V-blocks that can securely hold workpieces without the need for additional clamps. Choosing the right V-block for a specific task can significantly enhance both efficiency and precision in machining operations.

In conclusion, V-blocks are a fundamental component of the machinist's toolkit. Their ability to securely hold a variety of workpieces makes them invaluable for achieving precise machining results across many applications. Investing in high-quality V-blocks can lead to improved accuracy, heightened productivity, and ultimately a more successful machining process. Whether you are a hobbyist or a professional machinist, V-blocks are a smart addition to any workshop, facilitating a greater degree of precision that is vital in the field of engineering.

-

Right Angle Ruler Innovations in Measuring ToolsNewsJul.18,2025

-

Parallel Ruler Maintenance for Long-Term AccuracyNewsJul.18,2025

-

Magnetic V Block 4 Inch Cost Effectiveness AnalysisNewsJul.18,2025

-

Internal Thread Gauge Innovations for Faster InspectionNewsJul.18,2025

-

Ground Anchor Applications in Construction and LandscapingNewsJul.18,2025

-

Butterfly Valve Types StandardsNewsJul.18,2025

Related PRODUCTS