Aug . 07, 2024 10:05 Back to list

Exploring the Benefits and Uses of Pad Iron in Modern Construction and Metalworking Techniques

The Versatile World of Pad Iron An Essential Tool for Craftsmen

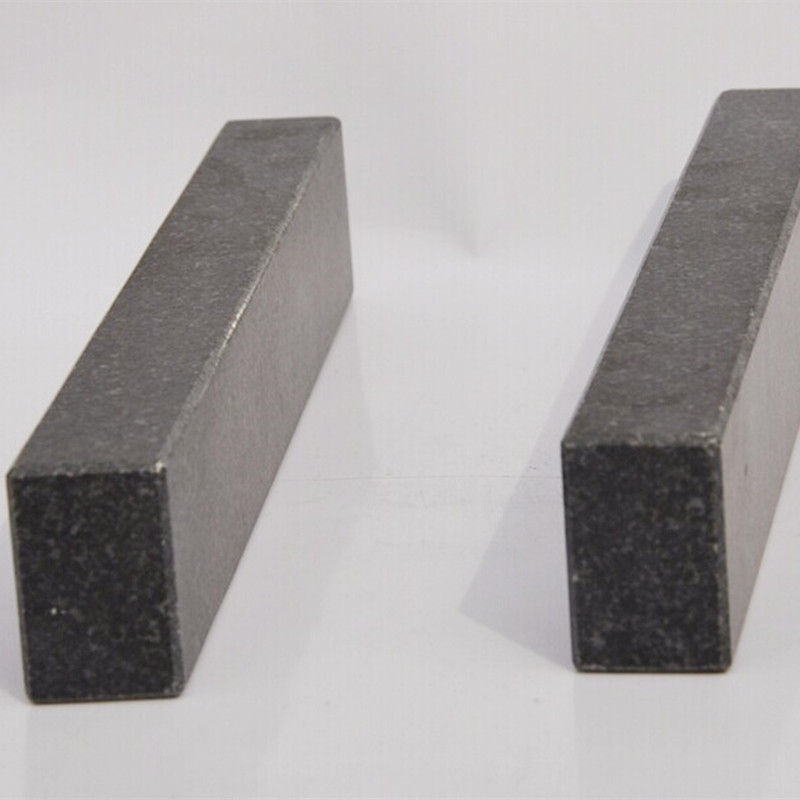

In the realm of metalworking, pad iron has emerged as a crucial component, appreciated for its versatility and durability. Pad iron, composed of various grades of steel, is a flat or slightly bent piece designed for specific applications, particularly in construction, manufacturing, and artisanal crafts. This article delves into the various aspects of pad iron, exploring its applications, benefits, and the role it plays in modern craftsmanship.

What is Pad Iron?

Pad iron is essentially a metal plate, often used as an additional support or reinforcement in various structures. It typically comes in a rectangular shape with dimensions varying from small, manageable sizes to larger sheets, depending on the intended use. As a metal plate, it can be easily cut, shaped, and welded, making it a favorite among artisans and industrial manufacturers alike.

Applications of Pad Iron

One of the most prevalent uses of pad iron is in the construction industry, where it serves as a critical component for enhancing structural integrity. For instance, pad iron plates are frequently utilized as supports for beams, columns, and girders, ensuring that the overall weight distributed across structures is managed effectively. This quality is paramount in settings where safety is a priority, such as bridges and high-rise buildings.

In addition to construction, pad iron finds its application in various manufacturing processes. It can be used to create braces, brackets, and fixtures that hold components in place during assembly. The automotive industry also takes advantage of pad iron for similar purposes, where precision and strength are necessary for vehicle safety and performance.

pad iron

Artisans, such as blacksmiths and metalworkers, enjoy the adaptability of pad iron in creating bespoke items. Whether for crafting decorative elements, tools, or functional hardware, the ease of manipulation allows for intricate designs while maintaining the structural strength required for practical use.

Benefits of Pad Iron

The choice of pad iron over other materials can be attributed to several benefits. Firstly, its high tensile strength ensures longevity, reducing the need for frequent replacements or repairs. This durability is particularly advantageous in environments that expose materials to various stresses and strains.

Moreover, pad iron is often corrosion-resistant, especially when treated or coated, making it suitable for both indoor and outdoor applications. This property is essential for items exposed to moisture or harsh weather conditions, where traditional metals might fail.

Another significant advantage is the ease of fabrication. Pad iron can be welded, cut, drilled, and shaped with relative ease, allowing craftsmen to adapt the material as needed without excessive effort or specialized equipment. This adaptability fosters creativity, enabling artisans to bring innovative ideas to fruition effectively.

Conclusion

In conclusion, pad iron stands out as an indispensable tool in the realm of craftsmanship and industry. Its diverse applications, coupled with its strength and adaptability, make it a favorable choice for builders, manufacturers, and artisans alike. As technology continues to evolve, the applications of pad iron could expand even further, cementing its role as a foundational element in a variety of projects. As we move forward into a future that emphasizes both artistry and structural integrity, the significance of pad iron will undoubtedly continue to rise, marking its place as a staple in the world of metalworking.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS