Aug . 15, 2024 08:23 Back to list

Exploring the Benefits and Applications of Vertical Guide Rails in Modern Engineering Solutions

Understanding Vertical Guide Rails A Comprehensive Overview

Vertical guide rails are essential components utilized in various industries, particularly in the realm of manufacturing and logistics. Their primary function is to facilitate the smooth and efficient movement of products, machinery, or automation systems along a designated path. By providing stable guidance, vertical guide rails enhance operational efficiency, improve worker safety, and contribute to the overall effectiveness of production processes.

What Are Vertical Guide Rails?

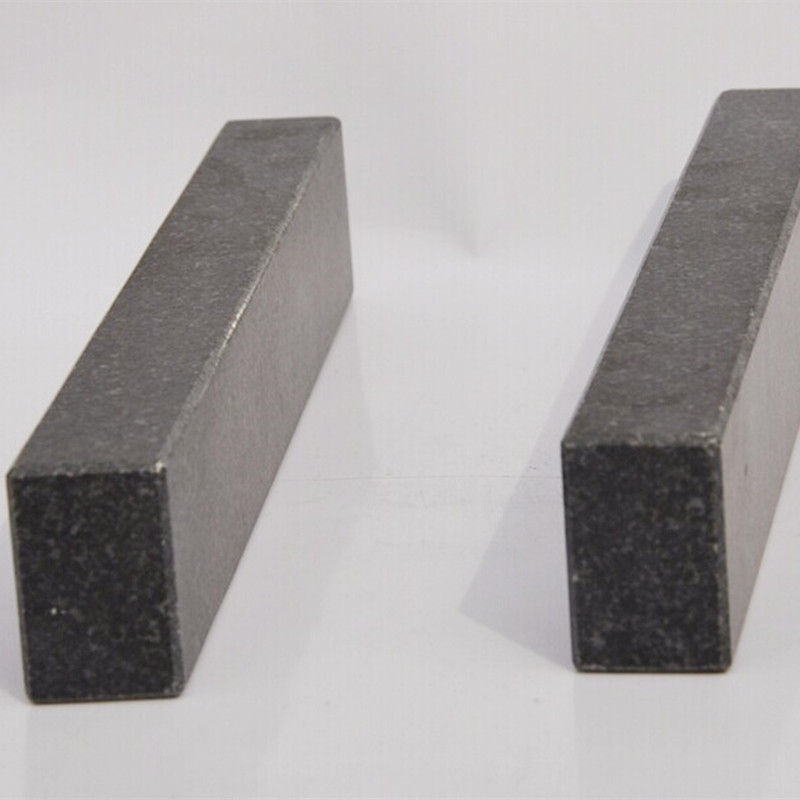

Vertical guide rails are linear supports that are often installed vertically to direct the movement of moving parts such as conveyor belts, lifts, or automated retrieval systems. Typically made from durable materials like steel or aluminum, these guide rails are designed to withstand heavy loads and adverse operating conditions. Their construction ensures long-lasting performance, making them a critical investment for many operational settings.

Applications of Vertical Guide Rails

1. Manufacturing In manufacturing plants, vertical guide rails are used in assembly lines to guide parts through various stages of production. They ensure that components are aligned accurately, thus minimizing the risk of jams or misalignment that could slow down production.

2. Logistics and Warehousing In warehouses, vertical guide rails contribute to the efficient operation of automated storage and retrieval systems (AS/RS). They help position retrieval units, ensuring that items are picked and delivered swiftly to maintain inventory turnover.

3. Material Handling In material handling systems, vertical guide rails allow for the safe and efficient movement of heavy materials. They prevent lateral movement that could lead to spills or accidents, thereby enhancing safety in the workplace.

4. Elevators and Lifts Vertical guide rails play a crucial role in elevators and lifts, providing the necessary support and alignment for safe vertical travel. They ensure that the elevator car remains stable, allowing passengers and cargo to move securely between floors.

vertical guide rails

Benefits of Vertical Guide Rails

The installation of vertical guide rails comes with numerous benefits

1. Increased Efficiency By providing a reliable path for movement, vertical guide rails minimize delays caused by misalignment or obstruction, leading to faster operations.

2. Enhanced Safety Vertical guide rails help to prevent accidents by keeping moving parts aligned. This reduces the likelihood of components falling or colliding, thereby protecting workers and equipment.

3. Reduced Maintenance Costs With enhanced alignment and stability, wear and tear on machinery is significantly reduced. This leads to less frequent breakdowns and lower maintenance costs over time.

4. Versatility Vertical guide rails can be customized for various applications, allowing companies to tailor solutions to their specific needs. Whether it’s for heavy machinery or delicate parts, vertical guide rails can accommodate a wide range of requirements.

Conclusion

In conclusion, vertical guide rails are indispensable in many industrial settings. They not only facilitate the efficient movement of materials and components but also contribute to safety and operational effectiveness. As industries continue to evolve and embrace automation, the importance of reliable guiding systems like vertical guide rails becomes even more pronounced. Investing in quality vertical guide rails can yield significant returns in productivity and safety, making them a critical component in the modern manufacturing and logistics landscape.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS