Jul . 24, 2024 01:22 Back to list

Exploring the Applications and Benefits of Tapered Ring Gauges in Precision Measurement Tools

Taper Ring Gauge A Crucial Tool in Precision Engineering

In the realm of engineering and manufacturing, precision is paramount. One of the key tools that help achieve this level of accuracy is the taper ring gauge. This specialized measuring instrument is primarily used to assess the dimensional accuracy of tapered components, ensuring they meet the necessary specifications for functionality and performance.

Understanding Taper Ring Gauges

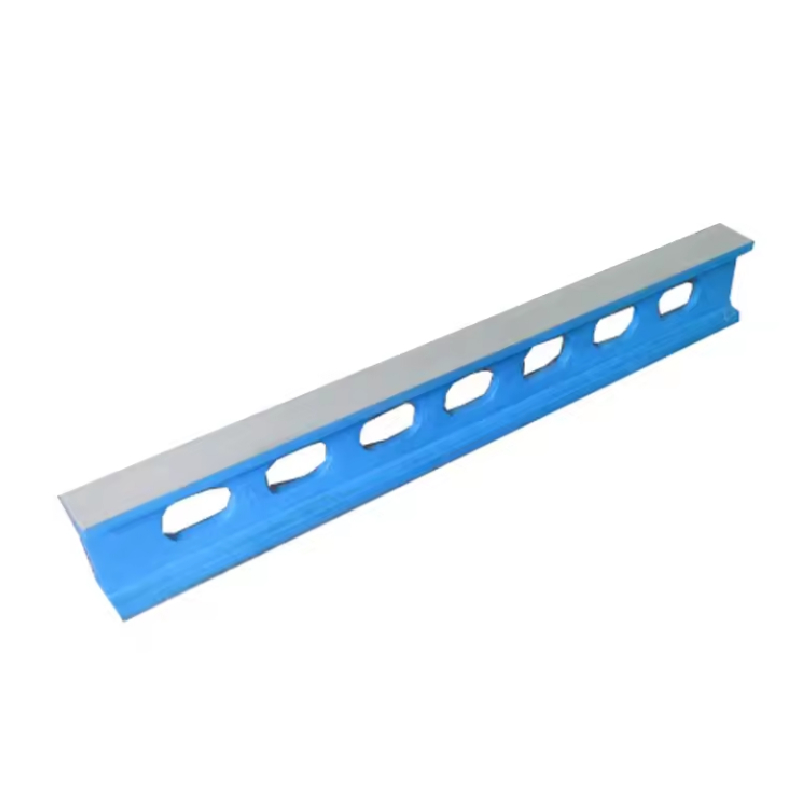

A taper ring gauge is designed with a conical shape, allowing it to fit over tapered objects such as shafts, pins, and bores. These gauges are typically made from high-quality steel or other durable materials, ensuring longevity and maintaining their calibration over time. The design features a series of graduated markings that correspond to specific measurements, enabling users to determine whether a given part adheres to the specified tolerances.

The taper ring gauge operates on the principle of interference fit. When a tapered workpiece is inserted into the gauge, any discrepancies in size or shape become evident. If the workpiece fits loosely or fails to enter the gauge entirely, it indicates that the component does not meet the required specifications. This simple yet effective method allows for quick and reliable assessment of taper dimensions.

Applications of Taper Ring Gauges

Taper ring gauges are indispensable in various industries including automotive, aerospace, and manufacturing. For instance, in the automotive industry, they are used to ensure that components such as engine parts and transmission shafts have the correct dimensions. Any deviation can lead to mechanical failure, compromising safety and performance.

taper ring gauge

In the aerospace sector, where precision is critical, taper ring gauges are used to verify the dimensions of components that must withstand high stresses and extreme conditions. The ability to quickly check the dimensional accuracy of components helps engineers and quality assurance teams maintain stringent quality control standards.

Moreover, taper ring gauges can also be employed in quality assurance processes during the manufacturing phase. By implementing regular checks using these gauges, manufacturers can minimize waste, reduce costs, and increase overall productivity.

Benefits of Using Taper Ring Gauges

One of the primary benefits of taper ring gauges is their simplicity and ease of use. Unlike electronic measuring tools that may require calibration and extensive training, taper ring gauges offer a straightforward approach to dimensional verification. Operators can perform checks quickly, allowing for fast-paced production environments to maintain efficiency without sacrificing quality.

Additionally, taper ring gauges are highly durable and can withstand harsh working conditions, making them ideal for various industrial applications. Their consistent performance ensures that users can rely on them for accurate measurements, which is critical in maintaining the integrity of components.

Conclusion

In conclusion, taper ring gauges play a vital role in modern precision engineering. They offer a simple, cost-effective solution for ensuring that tapered components meet exact specifications, thus maintaining the high standards required in various industries. As manufacturing processes continue to evolve, the importance of reliable measuring instruments like taper ring gauges will remain essential in achieving accuracy and efficiency in production. By understanding and utilizing these gauges, engineers can continue to produce high-quality, dependable products that meet the demands of today's marketplace. Whether in automotive, aerospace, or any other sector relying on precision-engineered components, taper ring gauges will remain a cornerstone of quality assurance practices.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS