Aug . 14, 2024 07:51 Back to list

Exploring Innovative Concepts and Designs in Modular Building Solutions for Modern Architecture

Understanding Vee Blocks Essential Tools for Precision in Metalworking

In the realm of metalworking, precision and accuracy are paramount, particularly in fabrication and machining processes. Among the various tools designed to ensure high precision in these environments, Vee blocks stand out due to their unique design and versatile applications. In this article, we will explore what Vee blocks are, their functionality, and their importance in the metalworking industry.

What are Vee Blocks?

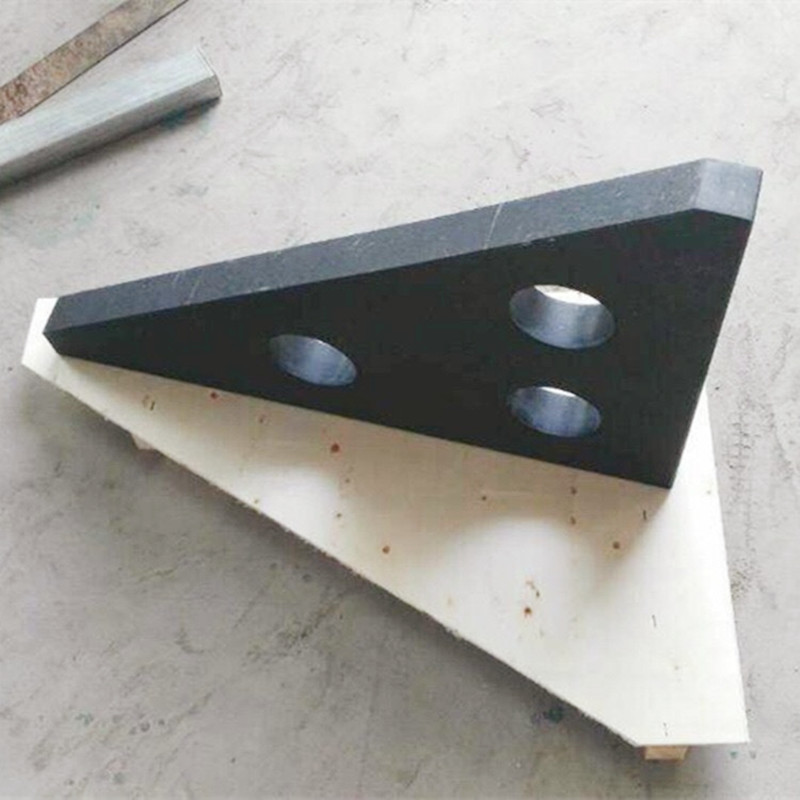

Vee blocks are specialized measuring tools used primarily for holding and aligning cylindrical workpieces during machining processes. Characterized by their 'V' shaped grooves, these blocks are typically made from hardened steel to withstand the rigors of machining and offer durability over time. The unique design allows workpieces, such as rods and pipes, to be securely positioned for accurate cutting, grinding, or inspection.

Functionality and Features

The primary function of Vee blocks is to provide a stable and precise location for holding cylindrical items. When a workpiece is placed in the Vee block, it is cradled securely, preventing any movement that could lead to inaccuracies in machining or measurement. This stability is crucial, as even the slightest misalignment can result in errors that can compromise the integrity of the final product.

Most Vee blocks come with an accompanying clamp or vice that securely holds the workpiece in place. Some models are even equipped with additional features such as threaded holes for mounting to a workbench or milling machine, enhancing their versatility. Furthermore, many Vee blocks are designed to be used in conjunction with other measuring tools, such as height gauges or calipers, further improving the accuracy of measurements.

Applications in Metalworking

vee blocks

Vee blocks are utilized across various applications in the metalworking industry. One of their most common uses is in the setup for grinding operations, where they hold cylindrical shafts or rods at precise angles. In addition, they are indispensable in inspection processes, providing a reference point for gauging the dimensions of workpieces, ensuring that they meet the required specifications.

Another significant application of Vee blocks is in welding. They provide a reliable means of supporting and aligning components while welding, ensuring that the parts fit together correctly and maintain alignment throughout the process. This capability not only enhances the quality of the weld but also improves overall productivity by reducing the likelihood of rework.

Importance of Vee Blocks

The importance of Vee blocks in metalworking cannot be overstated. Their ability to maintain alignment and stability enhances the precision of machining operations, ultimately leading to better-quality products. In an industry where accuracy is critical, the right tools can help businesses reduce waste, save time, and improve profitability.

Moreover, Vee blocks are available in various sizes and configurations, making them suitable for a wide range of applications. This versatility means that they can be utilized in small machine shops as well as in larger industrial settings, ensuring that every machinist has access to the tools they need to achieve precision.

Conclusion

In summary, Vee blocks are vital tools in the metalworking industry that play a crucial role in ensuring the accuracy and precision of machining operations. Their design and functionality enable machinists to securely hold and align cylindrical workpieces for cutting, grinding, or inspection. By using Vee blocks, metalworking professionals can enhance their productivity and ensure the quality of their final products, making them an indispensable part of the toolkit in modern machining environments.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS