Aug . 09, 2024 02:10 Back to list

Enhancing Structural Support with Unistrut Angle Braces for Versatile Applications in Construction Projects

Understanding Unistrut Angle Braces Applications and Advantages

Unistrut angle braces are essential components in the field of construction and engineering, primarily used to create support structures that require stability and resilience. These versatile braces are integral to various applications, including electrical installations, HVAC systems, and numerous support frameworks.

What is Unistrut?

Unistrut is a brand that has become synonymous with the modular support system. Originating from the manufacture of metal framing systems, Unistrut components include a plethora of brackets, channels, and braces, which can be easily assembled to support various structures. The angle brace, specifically, is a crucial element designed to add strength and rigidity to installations.

The Role of Angle Braces

Angle braces are typically L-shaped metal pieces that help prevent lateral movement of structures. By forming triangular shapes with connecting beams, these braces effectively distribute loads and enhance stability in installations. When employed correctly, they ensure that structures can withstand both static and dynamic loads, making them vital in environments where strength and durability are required.

Applications of Unistrut Angle Braces

One of the most common applications of Unistrut angle braces is in the electrical industry. They provide reliable support for electrical conduits, cable trays, and lighting fixtures. By using Unistrut systems, electricians can easily adjust and reposition their installations as necessary, accommodating changes in resources or structural designs.

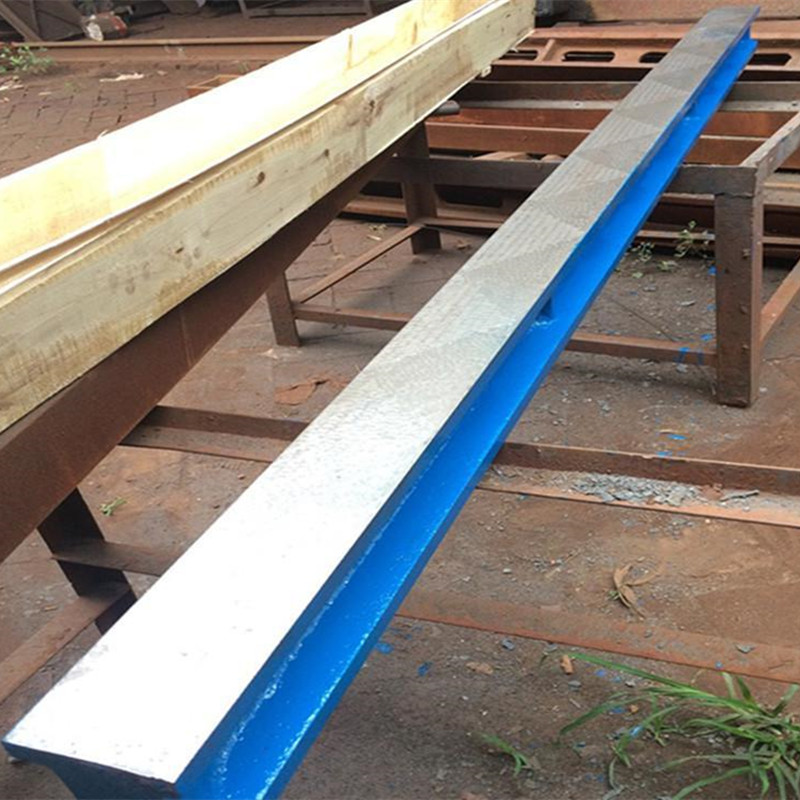

unistrut angle brace

Another critical application is in HVAC (heating, ventilation, and air conditioning) systems. Angle braces help hold ductwork secure against walls and ceilings, preventing sagging and ensuring optimal airflow. The flexibility of Unistrut systems enables HVAC professionals to design and install efficient systems quickly without sacrificing structural integrity.

In addition, angle braces are integral to constructing racks and shelving units in warehouses, retail spaces, and industrial facilities. The strength offered by these braces allows businesses to maximize vertical space, ensuring that products are stored safely and effectively.

Advantages of Unistrut Angle Braces

The use of Unistrut angle braces comes with several benefits. Firstly, their modular nature allows for rapid installation and modifications. Since Unistrut components can be easily reconfigured, they save time and resources during installation and adjustment periods. This flexibility is particularly advantageous in fast-paced industries where time is of the essence.

Secondly, the material used in manufacturing Unistrut braces, typically galvanized steel or aluminum, ensures durability and resistance to corrosion. This is especially relevant in environments prone to moisture or chemical exposure, where the longevity of support structures is paramount.

Thirdly, Unistrut angle braces contribute to enhanced safety in construction and engineering projects. By providing additional support and stability, they minimize the risk of structural failures that could lead to accidents or damage to equipment. Knowing that installations are reinforced with suitable braces gives engineers and builders peace of mind.

Conclusion

In summary, Unistrut angle braces play a vital role in various construction and engineering applications. Their ability to enhance stability, facilitate easy installation, and ensure long-lasting performance makes them an indispensable component in multiple industries. From electrical systems to HVAC installations and industrial shelving, the benefits of using Unistrut angle braces are evident. For anyone involved in construction and engineering, understanding and utilizing these braces can lead to more efficient, safe, and durable installations.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS