Aug . 01, 2024 03:27 Back to list

Effective Solutions for Reducing Mechanical Vibrations Using Advanced Damping Pads and Materials

Understanding Mechanical Vibration Damping Pads Their Importance and Applications

In various industrial and commercial applications, mechanical vibrations can have significant detrimental effects on machinery, structural integrity, and overall operational efficiency. Thus, the need for effective vibration management solutions has become increasingly important. One of the key components in addressing vibration issues is the use of mechanical vibration damping pads. These specialized pads offer a practical and effective way to mitigate vibrations, protect equipment, and enhance performance across a range of applications.

What Are Mechanical Vibration Damping Pads?

Mechanical vibration damping pads are engineered materials designed to absorb and dissipate vibrational energy. Typically made from elastomers, rubber composites, or other viscoelastic materials, these pads are strategically placed between machinery and the surfaces on which they are mounted. They work by converting kinetic energy from vibrations into heat through internal friction, effectively reducing the amplitude of the vibrations that can propagate through structures or equipment.

Key Benefits of Damping Pads

1. Vibration Reduction The primary benefit of damping pads is their ability to significantly reduce vibrations, which can lead to enhanced operational efficiency. This is crucial for machinery that operates at high speeds or that generates significant vibrational forces.

2. Equipment Protection Excessive vibrations can cause wear and tear on machinery over time. By using damping pads, businesses can prolong the lifespan of their equipment, reducing maintenance costs and minimizing unexpected downtimes.

3. Noise Reduction Vibrations often lead to increased noise levels in industrial settings. Damping pads help decrease both predicted and unintended noise, resulting in quieter working environments that can improve worker comfort and safety.

4. Improved Safety Uncontrolled vibrations can lead to hazardous situations, including equipment failure that may result in accidents. By utilizing damping pads, companies can create a safer operational environment.

5. Versatility Damping pads can be used in a variety of settings, from manufacturing plants to residential constructions. They can be found in applications ranging from HVAC systems and automotive parts to industrial machinery and consumer appliances.

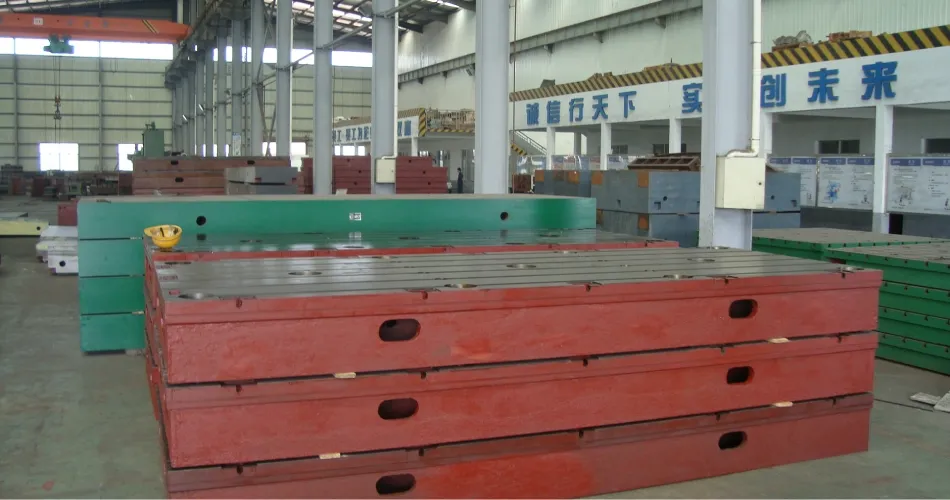

mechanical vibration damping pads

Applications of Damping Pads

Mechanical vibration damping pads find applications in diverse fields such as

- Manufacturing In this sector, they are utilized under heavy machinery, conveyors, and equipment to minimize vibration transmission, enhancing accuracy and surface finish of machined parts.

- Transportation In automotive and aerospace engineering, damping pads are crucial to diminishing vibrations and noise within vehicles, leading to improved ride quality and passenger comfort.

- HVAC Systems Vibration damping pads are frequently used under air conditioning units and chillers to reduce noise and vibrations, ensuring a comfortable indoor environment.

- Construction In buildings and bridges, damping pads mitigate the impact of external vibrations, such as those caused by nearby traffic or seismic activity, thereby preserving structural integrity.

- Electronics Sensitive electronic devices often require vibration damping to prevent interference and damage, making damping pads integral to manufacturing processes in this industry.

Conclusion

Mechanical vibration damping pads play an essential role in managing vibrations across various applications and industries. By absorbing and dissipating vibrational energy, these pads not only safeguard equipment and enhance safety but also improve overall operational efficiency. With the increasing need for precision and reliability in industrial processes, the adoption of vibration control solutions such as damping pads has never been more critical. As technology continues to advance, the development of even more effective and versatile damping materials will likely shape the future of vibration management, further bolstering their importance in modern engineering practices.

-

Ball Valve Body Types — Durable, Customizable, In StockNewsNov.05,2025

-

Spline Gauge Precision | Custom Design & ISO CertifiedNewsNov.04,2025

-

Ball Valve Body Types: Durable, Corrosion-Resistant BuildNewsNov.03,2025

-

Knife Edge Ruler | Precision Straightedge for InspectionNewsNov.03,2025

-

Inspection Ruler – Precision Measuring, Durable & CertifiedNewsNov.03,2025

-

Types of Micrometer: Pro-Grade Sets, Thread & StandardsNewsNov.03,2025

Related PRODUCTS