Jul . 26, 2024 09:35 Back to list

Durable Pipe Supports for Heavy-Duty Applications and Efficient Load Distribution Solutions

Understanding Heavy Duty Pipe Saddles Essential Components for Durable Support

Heavy duty pipe saddles are crucial components in various industrial applications, particularly in the realms of plumbing, construction, and infrastructure development. These saddles play a vital role in supporting pipes, ensuring a secure and stable installation that can withstand the rigors of heavy use and environmental stresses. In this article, we will delve into the features, applications, and advantages of heavy duty pipe saddles, highlighting their importance in maintaining the integrity of piping systems.

What are Heavy Duty Pipe Saddles?

Heavy duty pipe saddles are specially designed supports that provide stability to pipelines, particularly those that carry fluids or gases under high pressure. Typically made from robust materials such as stainless steel, PVC, or high-density polyethylene, these saddles are engineered to endure significant loads without bending or breaking. The primary function of a pipe saddle is to prevent pipe movement, reduce stress on joints, and distribute weight evenly across a surface.

Key Features of Heavy Duty Pipe Saddles

1. Load Capacity One of the defining characteristics of heavy duty pipe saddles is their high load-bearing capacity. They are constructed to support large diameter pipes that carry heavy materials, making them essential in industrial settings.

2. Durability Made from resilient materials, these saddles are resistant to corrosion, chemicals, and extreme temperatures. This durability ensures longevity, reducing the need for frequent replacements and maintenance.

3. Versatile Design Heavy duty pipe saddles come in various shapes and sizes to accommodate different pipe diameters and materials. This versatility allows for easy integration into existing systems, ensuring a secure fit.

4. Customizability Many manufacturers offer custom designs to meet specific project requirements, providing solutions tailored to unique piping configurations and load demands.

Applications of Heavy Duty Pipe Saddles

Heavy duty pipe saddles find applications across a broad spectrum of industries, including

heavy duty pipe saddles

- Oil and Gas In the oil and gas sector, these saddles support pipelines that transport crude oil and natural gas, ensuring they remain securely in place despite fluctuations in pressure and temperature.

- Water and Wastewater Management Pipe saddles are crucial in municipal water systems, where they support large pipes used in the distribution and treatment of water.

- Chemical Processing In facilities that handle corrosive substances, heavy duty saddles made from resistant materials are vital for maintaining operational safety and integrity.

- Construction In construction projects, these saddles are used to support HVAC systems and other piping installations, ensuring they meet building codes and safety standards.

Advantages of Using Heavy Duty Pipe Saddles

1. Enhanced Stability By providing a stable support structure, heavy duty pipe saddles reduce the risk of pipe sagging or movement, thereby preventing potential leaks and breaks.

2. Safety A secure piping system is crucial for safety in any industrial environment. Heavy duty saddles help maintain the integrity of pipelines, reducing the risk of accidents associated with pipe failure.

3. Cost-Efficiency Although the initial investment may be higher, the durability and reliability of heavy duty pipe saddles can lead to significant savings over time through reduced maintenance and downtime.

4. Ease of Installation Many heavy duty pipe saddles are designed for quick and straightforward installation, which helps project timelines and minimizes labor costs.

Conclusion

Heavy duty pipe saddles are indispensable in maintaining the stability and safety of various piping systems. Their robust construction, versatility, and easy installation make them a preferred choice for industries requiring reliable support for heavy-duty pipelines. By investing in high-quality pipe saddles, companies can ensure the longevity of their piping systems and contribute to a safer, more efficient operational environment.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

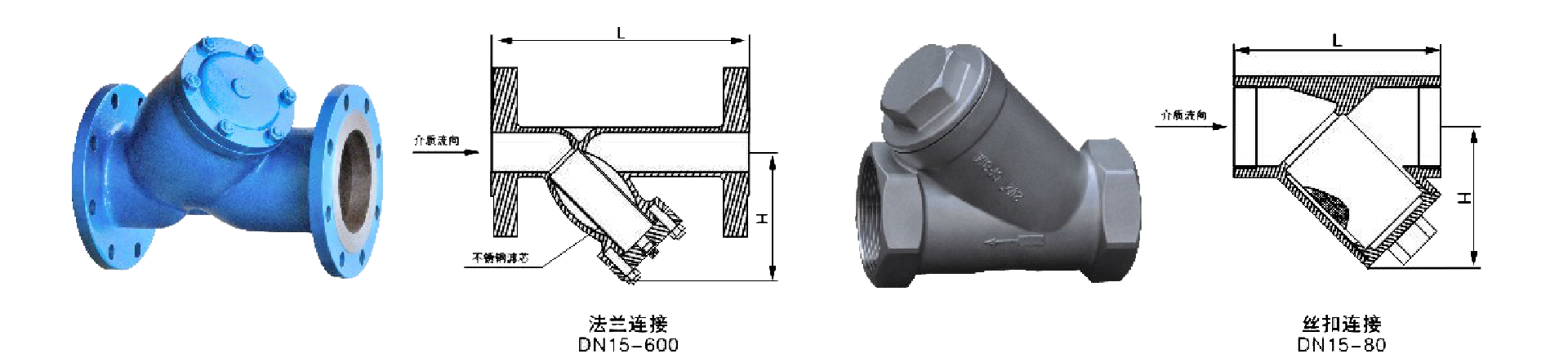

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS