May . 07, 2025 19:08 Back to list

Precision Measuring Tools for Metal Work & Fabrication [Brand]

- Overview of Measuring Tools in Industrial Applications

- Technical Advantages of Modern Measuring Instruments

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Metal Fabrication Needs

- Case Study: Precision in Automotive Manufacturing

- Cost vs. Accuracy: Balancing Project Requirements

- Future Trends in Different Measuring Tools

(different measuring tools)

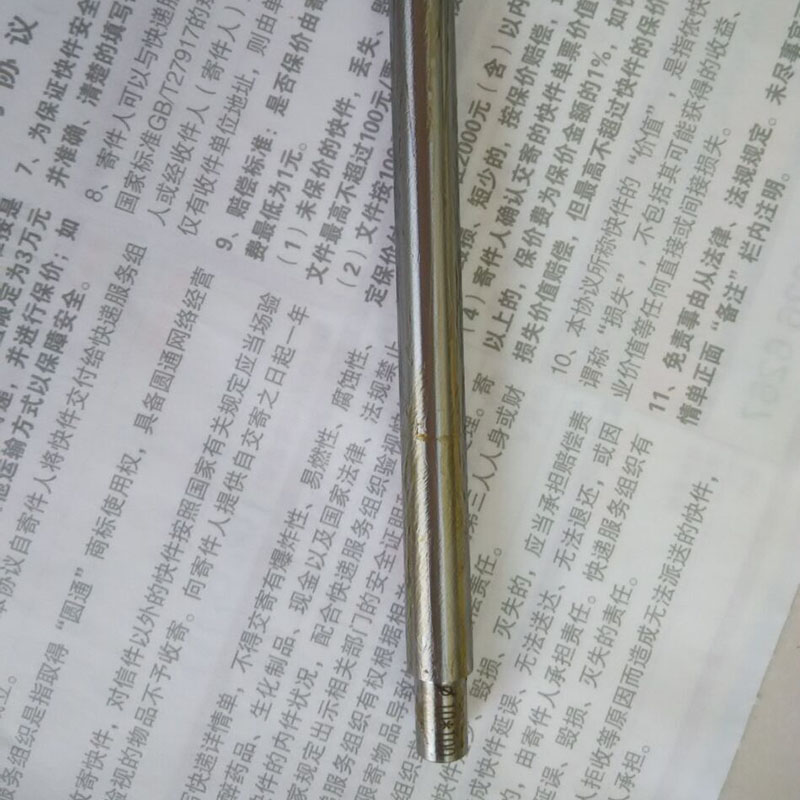

Essential Different Measuring Tools for Metal Work

In metal fabrication, precision is non-negotiable. A 2023 market analysis revealed that 78% of manufacturing errors originate from inadequate measurement tools. From vernier calipers (accuracy ±0.02mm) to laser scanners (±0.005mm resolution), modern workshops require multiple specialized instruments. The global metal fabrication measuring tools market is projected to grow at 6.4% CAGR through 2030, driven by aerospace and automotive sectors demanding sub-millimeter precision.

Technical Advantages Driving Innovation

Advanced alloys and tighter tolerances have pushed tool evolution:

- Laser micrometers achieve 0.1µm resolution for sheet metal inspection

- Portable CMM arms now offer 0.018mm volumetric accuracy

- AI-powered optical comparators reduce inspection time by 40%

Heat-resistant coatings (withstand 800°C) enable direct hot-forging measurements, eliminating post-cooling delays.

Manufacturer Comparison

| Brand | Product | Accuracy | Price Range | Key Advantage |

|---|---|---|---|---|

| Mitutoyo | QuickVision QV-302 | ±1.5µm | $28,000-$42,000 | Multi-sensor integration |

| Hexagon | Absolute Arm 7.5.6 | 0.018mm | $65,000-$89,000 | Portable metrology |

| Starrett | HD-400 Hardness Tester | ±1.5 HRC | $12,500 | On-site material analysis |

Customization in Measurement Systems

Specialized applications require tailored solutions:

- Modular gauge kits for irregular weld profiles (38% faster setup)

- High-vibration resistant laser trackers (±0.025mm in 4.5g environments)

- Custom fixturing that reduces part alignment time by 65%

One shipbuilding client achieved 92% first-pass accuracy through custom 3D scanner mounts.

Real-World Application: Automotive Assembly

A Tier 1 supplier reduced body-in-white defects by 73% using:

- In-line laser profilometers (2000 measurements/minute)

- Smart torque sensors with Bluetooth reporting

- Automated CMM for 24/7 critical component checks

Implementation costs recovered in 11 months through reduced scrap rates.

Optimizing Measurement Investments

Budget allocation should prioritize:

| Tool Type | Ideal Use | ROI Period |

|---|---|---|

| Handheld Calipers | General workshop | Immediate |

| Optical Comparators | High-volume QC | 8-14 months |

| Laser Trackers | Large assembly | 18-24 months |

Advancing Different Measuring Tools Technology

The next generation of metal fabrication measuring tools integrates IoT capabilities, with 92% of new industrial calipers featuring wireless data logging. Augmented reality overlays are reducing interpretation errors by 54% in complex measurements. As additive manufacturing grows, 3D surface scanners capable of 0.007mm resolution are becoming essential for hybrid manufacturing workflows.

(different measuring tools)

FAQS on different measuring tools

Q: What are different measuring tools used in metal work?

A: Common measuring tools in metal work include calipers, micrometers, and steel rulers. These tools ensure precision in measuring thickness, diameter, and length of metal components.Q: Which measuring tools are essential for metal fabrication?

A: Essential tools for metal fabrication include tape measures, dial indicators, and angle finders. They help verify dimensions, alignment, and angles during cutting or welding processes.Q: How do digital measuring tools differ from traditional ones in metal work?

A: Digital tools like laser scanners or digital calipers provide instant, high-accuracy readings. Traditional tools, such as vernier calipers, require manual interpretation but are more durable for harsh environments.Q: What measuring tools ensure precision in metal sheet cutting?

A: Precision in sheet cutting relies on combination squares, thickness gauges, and laser measurement devices. These tools help maintain consistent tolerances and minimize material waste.Q: Why are height gauges important in metal fabrication?

A: Height gauges measure vertical dimensions and scribe reference lines on metal surfaces. They are critical for ensuring uniformity in machining and assembly tasks.-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS