Aug . 22, 2024 03:36 Back to list

Comprehensive Review of Full Flow Check Valve Efficiency and Applications

Understanding Full Flow Check Valves Function, Types, and Applications

Full flow check valves are critical components in various industrial and commercial systems, designed to ensure the unidirectional flow of fluids and prevent backflow. These valves play a vital role in maintaining system integrity, safety, and efficiency across multiple applications, from water supply systems to sophisticated manufacturing processes. This article delves into the functionalities, types, and applications of full flow check valves, highlighting their significance in modern engineering.

What is a Full Flow Check Valve?

A full flow check valve, essentially, is a mechanical device that allows fluid to flow in one direction while automatically preventing reverse flow. This functionality is achieved through a sealing mechanism that engages when there is no flow in the reverse direction. Full flow check valves are particularly advantageous as they minimize pressure drop across the valve, allowing for optimal flow efficiency.

The design of these valves ensures that the pressure loss is negligible, making them suitable for high-capacity systems. This feature is paramount in applications where large volumes of fluid need to be transported efficiently while preventing any potential backflow that can cause contamination or system failures.

Types of Full Flow Check Valves

Full flow check valves come in various types, each catering to specific operational needs and conditions

1. Swing Check Valves These valves operate with a disc that hinges on a pin. When fluid flows in the designated direction, the disc swings open; if backflow occurs, the disc swings back to seal off the flow. Swing check valves are commonly used in water and wastewater applications.

2. Lift Check Valves These valves have a disc that lifts off its seat when flow is directed forward. In the event of backflow, the disc returns to its seat, effectively blocking reverse flow. Lift check valves are often utilized in steam and gas systems.

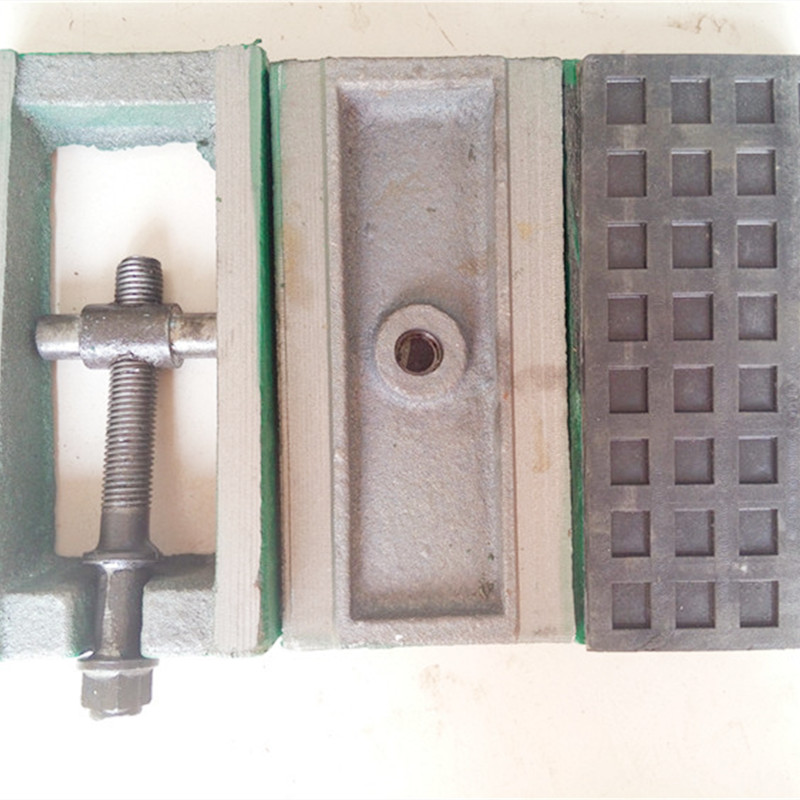

full flow check valve

3. Dual Plate Check Valves These valves contain two spring-loaded plates that open with forward flow and close with reverse flow. Their compact design and low-pressure drop make them popular in pipeline systems, especially those requiring quick response times.

4. Ball Check Valves These valves use a ball that moves within a chamber. When forward flow occurs, the ball is pushed away from the seat. Conversely, backflow causes the ball to seat against the opening, preventing any reverse flow. Ball check valves are widely applied in irrigation and drainage systems.

Applications of Full Flow Check Valves

Full flow check valves find applications across diverse industries due to their reliability and efficiency. Some notable applications include

- Water Supply Systems Used in municipal water supply systems to prevent backflow and ensure clean water reaches consumers without contamination. - Wastewater Treatment Essential in wastewater facilities to prevent contaminated water from returning to the system, thus safeguarding the environment. - Oil and Gas Utilized in pipelines to prevent backflow of product, which could otherwise result in leaks and environmental hazards. - HVAC Systems Employed in heating, ventilation, and air conditioning systems to maintain the desired flow direction and enhance system efficiency.

- Industrial Processes Used in various manufacturing processes, including chemical production, where maintaining flow direction is critical for product quality and safety.

Conclusion

In summary, full flow check valves are indispensable components that enhance system performance and reliability in a variety of applications. Their ability to ensure unidirectional flow while minimizing pressure drop makes them a popular choice in many industries. As technology advances, the design and functionality of check valves continue to evolve, further emphasizing their importance in modern fluid management systems. Understanding the types and applications of full flow check valves is crucial for engineers and professionals aiming to optimize system integrity and efficiency.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS