Jul . 27, 2024 16:15 Back to list

Comparing the Properties and Applications of Cast Iron and Engine Block Materials for Performance

Cast Iron vs. Engine Block A Comprehensive Comparison

When it comes to engine manufacturing and automotive performance, the choice of material is crucial. Among the most popular materials for engine blocks are cast iron and aluminum, each offering distinct advantages and disadvantages. This article aims to provide an in-depth comparison between cast iron and aluminum engine blocks, focusing on durability, weight, thermal conductivity, cost, and overall performance.

Durability and Strength

Cast iron has been a traditional choice for engine blocks for decades, primarily due to its incredible durability and strength. The unique composition of cast iron allows it to withstand high temperatures and pressures, making it highly resistant to wear over time. It can handle the rigors of high-performance applications without deforming or cracking, which is essential for reliability in heavy-duty vehicles and high-performance motorsports.

On the other hand, aluminum, although lighter, is generally considered less durable than cast iron. While modern aluminum alloys have made significant improvements in strength, they can be more susceptible to warping or cracking, especially under extreme conditions. However, advances in casting techniques and manufacturing have led to the development of high-strength aluminum options that are increasingly used in performance applications.

Weight and Performance

One of the most significant differences between cast iron and aluminum engine blocks is weight. Aluminum is significantly lighter, which translates to better overall vehicle performance. A lighter engine contributes to improved acceleration, handling, and fuel efficiency. Many automakers have shifted towards aluminum in their newer models to capitalize on these benefits.

However, the lightweight nature of aluminum can come with trade-offs regarding engine stability. A cast iron engine block’s greater mass can sometimes contribute to a more stable engine operation, reducing vibrations. This can lead to a smoother performance, particularly in larger vehicles. The decision between weight and stability ultimately depends on the specific application and performance requirements of the vehicle.

Thermal Conductivity

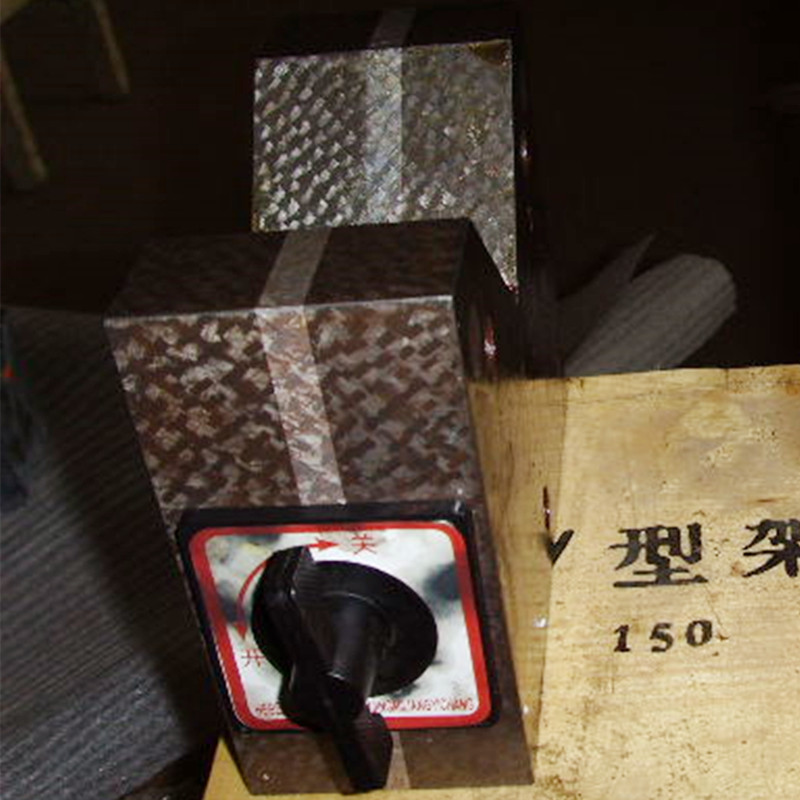

cast iron v block

Another critical factor is thermal conductivity. Aluminum excels in this category; it dissipates heat more efficiently than cast iron. This property allows aluminum engine blocks to maintain optimal operating temperatures more effectively, which is particularly advantageous in high-performance engines. Efficient heat management can lead to increased horsepower and torque, making aluminum a popular choice for sports cars and racing applications.

In contrast, while cast iron does not conduct heat as well as aluminum, it has superior heat retention properties. This can be beneficial in certain scenarios, such as for engines that operate at consistent high temperatures. However, in terms of rapid warmth during initial engine starts and cooling down, aluminum has the upper hand.

Cost Considerations

From a cost perspective, cast iron tends to be more economically viable. The material is less expensive, and the manufacturing processes are more established, leading to reduced production costs. In contrast, aluminum engine blocks are typically more costly due to the material price and the complexity of the manufacturing process.

The choice between cast iron and aluminum can, therefore, be influenced by budget constraints, with many traditional manufacturers opting for cast iron to keep expenses down.

Conclusion

In summary, the comparison between cast iron and aluminum engine blocks reveals a balance of strengths and weaknesses. Cast iron is celebrated for its durability, weight stability, and cost-effectiveness, making it suitable for heavy-duty and traditional applications. Meanwhile, aluminum shines with its lightweight characteristics, superior thermal conductivity, and increased performance capabilities.

Ultimately, the choice between cast iron and aluminum will depend on the specific application, performance needs, and budget considerations. As automotive technology continues to evolve, both materials will likely coexist, each serving unique roles in the world of engine manufacturing.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS