Sep . 03, 2024 04:16 Back to list

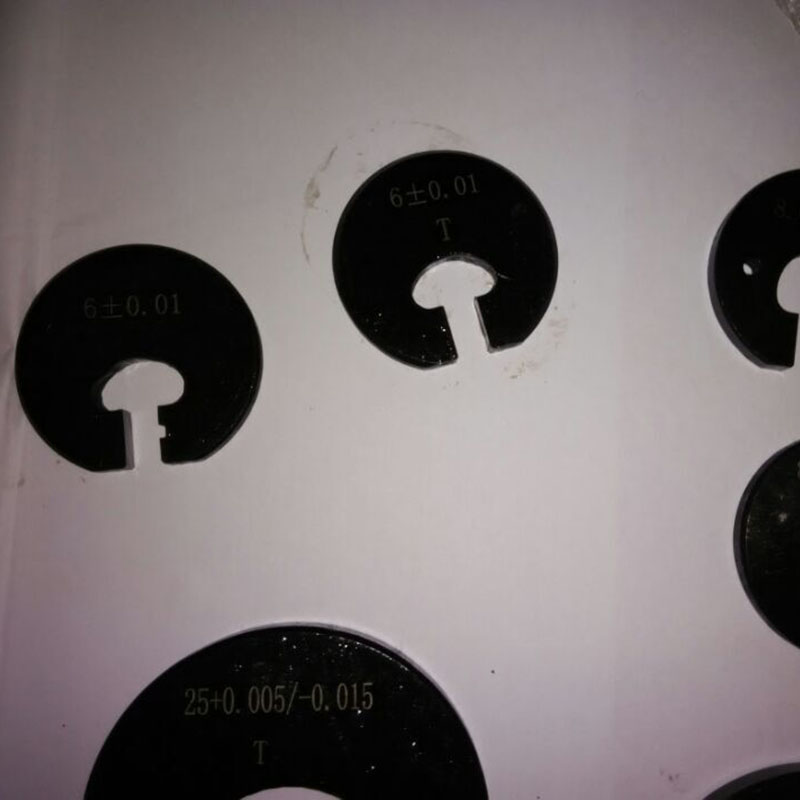

check valve 8

Understanding Check Valve 8 A Key Component in Fluid Control Systems

Check valves are essential components in various fluid control systems, ensuring that the flow of liquids or gases occurs in the intended direction while preventing backflow. Among the myriad types of check valves, Check Valve 8 has emerged as a notable standard in industrial applications, particularly due to its efficiency, reliability, and versatility.

Understanding Check Valve 8 A Key Component in Fluid Control Systems

One of the most significant advantages of Check Valve 8 is its adaptability in various applications. It is commonly used in water treatment facilities, chemical processing plants, and oil and gas industries. In these sectors, maintaining the integrity of fluid flow is crucial. A failure in a check valve can lead to catastrophic results, including potential contamination of crucial fluids and environmental hazards.

check valve 8

The design of Check Valve 8 also emphasizes durability and ease of maintenance. Typically constructed from robust materials like stainless steel or PVC, these valves can withstand harsh conditions and corrosive substances. Furthermore, the valve is engineered for easy disassembly, allowing for quick inspections and maintenance without the need for specialized tools. This feature significantly reduces downtime, which is critical in industrial operations where every minute counts.

Another noteworthy aspect of Check Valve 8 is its role in energy efficiency. By preventing backflow, these valves help maintain pressure levels within a system, reducing the energy required to pump fluids. This not only results in cost savings but also aligns with the growing emphasis on sustainability within industries. Efficient valve systems contribute to the overall energy management strategies that many companies are adopting to minimize their carbon footprint.

Moreover, Check Valve 8 is designed with a wide range of pressure ratings and sizes, making it suitable for both large-scale industrial applications and smaller residential setups. This flexibility allows engineers and system designers to incorporate it into diverse projects, ensuring optimal functionality.

In conclusion, Check Valve 8 is a critical component in the realm of fluid control systems. Its reliable performance, durability, and adaptability make it a preferred choice for engineers across various industries. As technology continues to evolve, innovations in valve design and materials will likely enhance the capabilities of Check Valve 8 even further, solidifying its role as a cornerstone in fluid management solutions. By understanding and effectively utilizing Check Valve 8, industries can ensure safe, efficient, and sustainable operations.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS