Sep . 07, 2024 01:54 Back to list

50mm Check Valve - Reliable Flow Control Solution

Understanding the Importance of 50mm Check Valves in Fluid Systems

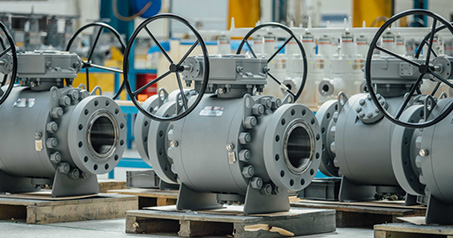

Check valves are critical components in various fluid handling systems, ensuring the prevention of backflow and maintaining the unidirectional flow of liquids or gases. Among the different types and sizes available, 50mm check valves stand out due to their versatility and wide application across various industries such as water treatment, oil and gas, and HVAC systems.

A 50mm check valve is designed to allow fluid to flow through it in one direction only. This is achieved through a simple mechanism where a flap or disk within the valve opens when fluid pressure pushes it in the forward direction. Conversely, if there is any tendency for the fluid to backflow, the flap seals tightly against the valve seat, preventing any reverse flow. This fundamental operation is vital for maintaining system pressure, avoiding damage to pumps, and ensuring the efficiency of fluid transport.

Understanding the Importance of 50mm Check Valves in Fluid Systems

Material selection is another crucial aspect of check valve design. A 50mm check valve can be constructed from various materials, including PVC, stainless steel, and bronze. The choice of material typically depends on the application, fluid type, and operating conditions, such as temperature and pressure. For instance, PVC check valves are common in chemical processing due to their excellent resistance to corrosion, while stainless steel valves are preferred in high-pressure steam applications.

check valve 50mm

Installation of a 50mm check valve is also straightforward, making it accessible for both professional engineers and DIY enthusiasts. It can be placed in horizontal or vertical piping systems, although it's essential to follow manufacturer guidelines to ensure optimal performance. Proper installation helps in reducing turbulence and ensuring that the swift flow of fluid does not cause excessive wear or failure of the valve over time.

Maintenance is a vital consideration for any check valve, including the 50mm variant. Regular inspections are recommended to ensure that the valve is functioning correctly. Signs of wear, such as leaks or an inability to open and close, should be promptly addressed. In some cases, the valve may require cleaning or replacement of the sealing elements to restore optimal functionality.

In industrial and commercial applications, the use of 50mm check valves can greatly enhance system reliability, minimize leakages, and improve overall safety. They are available in various designs, including spring-loaded and gravity-operated types, catering to specific operational needs and fluid characteristics.

In conclusion, 50mm check valves are indispensable components in fluid systems, providing crucial protection against backflow and ensuring the efficient transport of liquids and gases. Understanding their function, material properties, and maintenance needs can help industries choose the right valves for their applications, enhancing system reliability and operational effectiveness. Whether used in municipal water supply systems, industrial processes, or residential plumbing, the importance of these valves cannot be overstated.

-

Thread Micrometer Set FeaturesNewsJul.04,2025

-

Right Angle Ruler Tool for WoodworkingNewsJul.04,2025

-

Precision Frame Level Calibration StepsNewsJul.04,2025

-

Magnetic Vee Block MaterialsNewsJul.04,2025

-

Heavy Duty Ground Anchors in MiningNewsJul.04,2025

-

Features of Welding Table Cast IronNewsJul.04,2025

Related PRODUCTS