Dec . 11, 2024 12:29 Back to list

Exploring the Benefits of Cast Iron Surface Tables in Precision Engineering

The Significance of Cast Iron Surface Tables in Precision Engineering

In the world of precision engineering, the importance of measurement and flatness cannot be overstated. At the heart of this meticulous field lies the cast iron surface table, a cornerstone tool revered for its durability, stability, and accuracy. Designed to provide a perfectly flat plane for the inspection, assembly, and machining of components, these tables play a crucial role in ensuring the quality and reliability of engineering products.

What is a Cast Iron Surface Table?

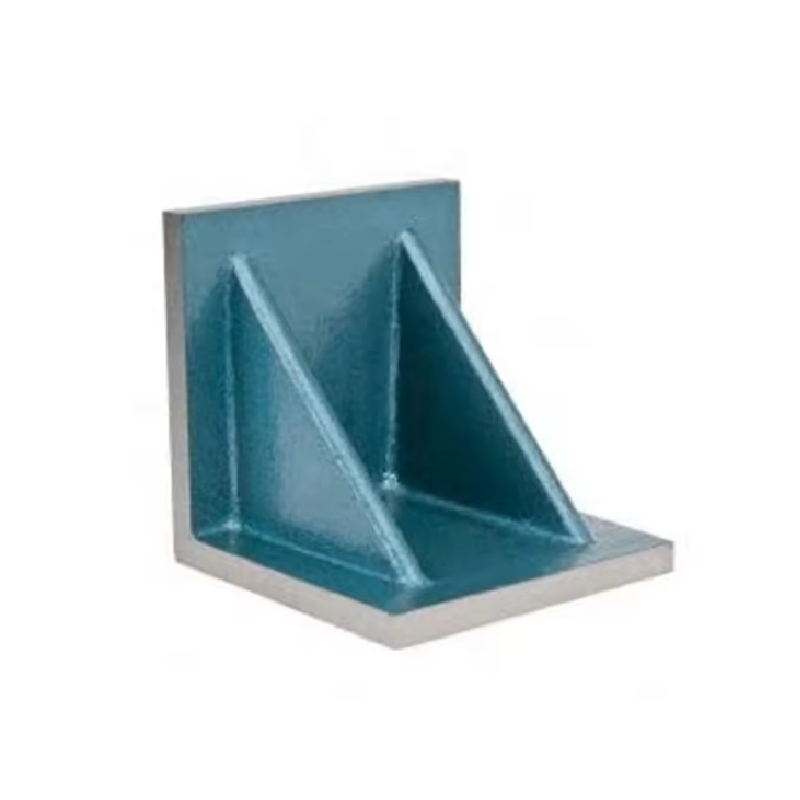

A cast iron surface table is a flat workstation made from high-quality cast iron, known for its exceptional rigidity and resistance to deformation. These tables are typically ground to ensure a smooth, flat surface, which is essential for precise measurements. The flatness and size of the table are critical because even the slightest deviation can lead to inaccuracies in measurements, ultimately affecting the quality of the workpiece.

Characteristics of Cast Iron Surface Tables

Cast iron is the material of choice for these tables due to its unique properties. One of the primary characteristics of cast iron is its ability to dampen vibrations. This is particularly important during measurements, as vibrations can lead to errors and inconsistencies. Additionally, cast iron has excellent wear resistance, allowing it to maintain its flatness over time, even under the weight of heavy workpieces.

Another advantage of cast iron is its thermal stability. Unlike other materials, cast iron doesn’t expand or contract significantly with temperature changes, which means that the surface table can provide consistent measurement accuracy in varying environmental conditions. This quality is particularly vital in precision engineering, where even minor fluctuations can lead to significant discrepancies.

Applications of Cast Iron Surface Tables

cast iron surface table

The applications of cast iron surface tables are varied and vast. They are commonly used in manufacturing settings for quality assurance during the inspection of machined components. By placing a workpiece on a cast iron surface table and using precision measuring instruments, engineers can accurately assess the dimensional accuracy of the component.

These tables are also used in the assembly of complex machinery and equipment. For example, when assembling high-precision instruments or intricate mechanical assemblies, a cast iron surface table provides a stable platform that aids in aligning components accurately.

Moreover, cast iron surface tables are indispensable in tool and die making. They allow machinists to set up equipment with high precision, ensuring that cuts and measurements are executed flawlessly. This not only saves time but also enhances the overall quality of the tooling produced.

Maintenance of Cast Iron Surface Tables

To ensure longevity and preserve their accuracy, cast iron surface tables require regular maintenance. It is essential to keep their surface clean and free from debris that can scratch or mar the flatness. Periodic checks should be performed to assess the flatness of the surface, and any needed repairs should be executed promptly to maintain optimal performance.

Furthermore, cast iron surfaces should be protected from moisture to prevent rust formation, which can compromise the table’s integrity. Using a protective oil or coating can significantly increase the lifespan of the table and maintain its precision.

Conclusion

In conclusion, cast iron surface tables are integral to the field of precision engineering. Their combination of durability, stability, and accuracy makes them an invaluable tool for manufacturers, machinists, and engineers alike. As industries continue to demand higher levels of precision and quality, the role of cast iron surface tables will only grow in importance. Investing in a high-quality surface table is not merely a practical decision; it's a commitment to excellence in engineering and manufacturing. With careful maintenance and proper use, these tables will continue to serve as a reliable foundation for measuring, assembling, and machining components for years to come.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS