Sep . 29, 2024 02:57 Back to list

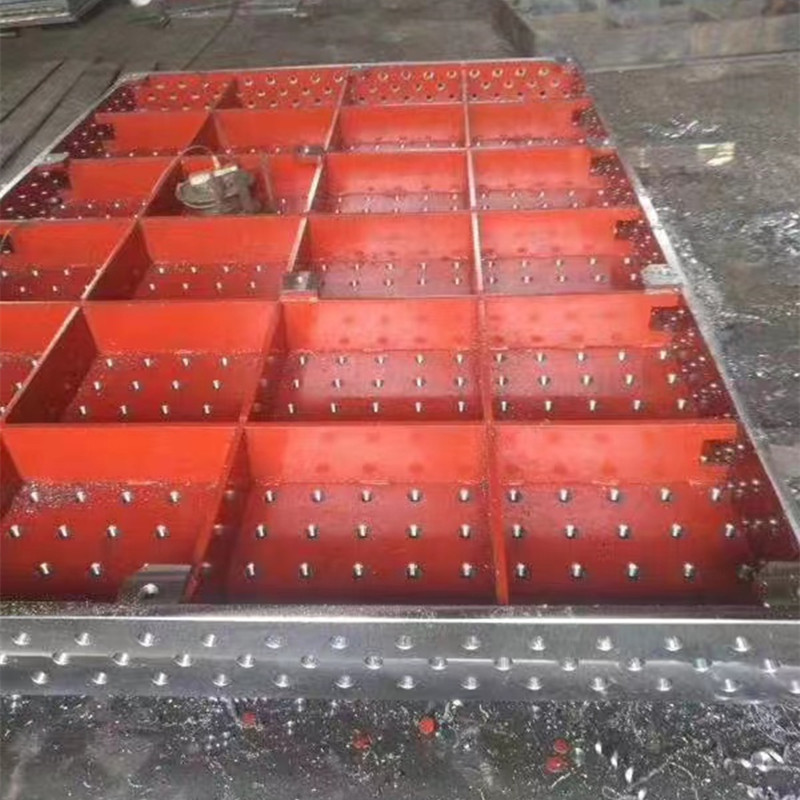

High-Performance Cast Iron Lapping Plates for Precision Surface Finishing Applications

The Utility and Importance of Cast Iron Lapping Plates

Lapping, a precision machining process, is used to achieve extremely flat and smooth surfaces on various materials. Among the tools employed in lapping processes, cast iron lapping plates have gained significant prominence in manufacturing and engineering industries. The unique properties of cast iron make these plates highly effective and desirable for a wide range of applications.

Physical Properties of Cast Iron

Cast iron is an alloy of iron that contains carbon, silicon, and other elements. Its composition gives it distinctive physical properties, making it an excellent choice for lapping plates. Cast iron is known for its excellent wear resistance, rigidity, and ability to maintain its shape over time. The flatness and smooth surfaces required for precision lapping are achieved through a methodical casting process that ensures consistency and uniformity.

The porous structure of cast iron also plays a crucial role in the lapping process. When a cast iron plate is used, the microscopic pores can hold lapping compounds, which are often abrasive materials mixed with lubricants. This allows the plate to evenly distribute the abrasive particles across its surface, facilitating a more uniform lapping process that enhances the polishing and flattening of the workpieces.

Versatile Applications

Cast iron lapping plates are utilized in various industries, including automotive, aerospace, and electronics. They are primarily used to finish flat surfaces on components such as valves, gears, and precision instruments. The need for exceptionally flat and smooth surfaces is critical in these applications, where even the slightest imperfection can lead to operational failures or reduced efficiency.

In the automotive industry, for example, cast iron lapping plates are used for machining engine components. The precision achieved through lapping ensures that parts fit together correctly, promoting optimal performance. Similarly, in the aerospace sector, manufacturers rely on lapping plates to ensure the surfaces of critical components meet stringent safety and performance standards.

Healthcare equipment manufacturing also benefits from the use of cast iron lapping plates. Surgical instruments and prosthetic devices require smooth surfaces to meet regulatory standards and to ensure the safety of patients. As such, the precision achieved through lapping contributes significantly to manufacturing processes in this field.

cast iron lapping plate

Advantages Over Other Materials

While lapping plates can be made from various materials, the advantages of cast iron make it a preferred choice. One significant benefit is cost-effectiveness. Cast iron is relatively inexpensive compared to other lapping plate materials such as granite or aluminum. Additionally, cast iron is less prone to thermal expansion, meaning it maintains its flatness over a wider range of temperatures, which is crucial in precision applications.

Moreover, cast iron’s durability and wear resistance translate to longer-lasting lapping plates. Unlike softer materials, cast iron can withstand the mechanical stresses of lapping operations without warping or degrading. This longevity adds to its cost-effectiveness, as manufacturers do not need to replace lapping plates as frequently.

Maintenance and Care

To ensure the longevity of cast iron lapping plates, proper maintenance is essential. Regular cleaning of the plates is necessary to remove any debris or abrasive particles that could compromise surface integrity. It's also crucial to periodically check the flatness of the plates. Most manufacturers recommend using a flatness gauge or similar tools to maintain precision.

Additionally, applying a light coat of oil can help protect the surface from rust and corrosion, ensuring the plates remain effective for years of service.

Conclusion

Cast iron lapping plates represent a critical tool in myriad precision machining processes. Their unique properties, versatility, and cost-effectiveness make them an indispensable component in ensuring the quality of finished products across various industries. As manufacturing continues to evolve, the relevance and application of cast iron lapping plates are likely to remain significant, proving their worth in delivering precision and excellence. Whether in automotive, aerospace, electronics, or healthcare, these plates symbolize an enduring commitment to quality engineering and manufacturing standards, underscoring their importance in today’s industrial landscape.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS