Jun . 26, 2024 14:19 Back to list

Cast Iron Welding Table Enhancing Welding Precision and Stability

The Significance of Welding Tables Made from Cast Iron

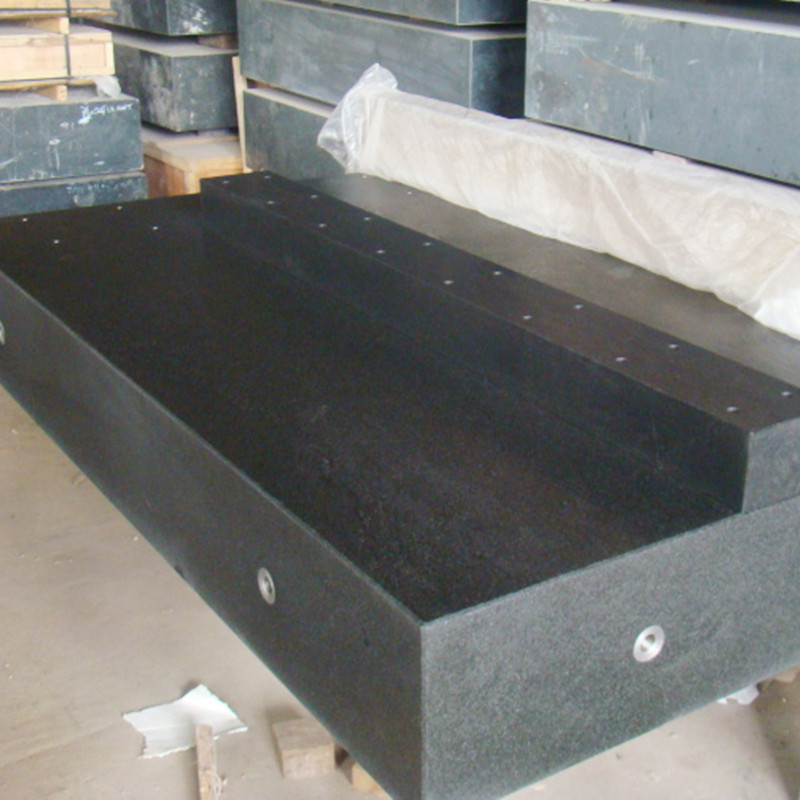

Welding, an essential process in fabrication and manufacturing, demands precision, stability, and durability. A welding table plays a pivotal role in ensuring these factors, and when it comes to material choice, cast iron welding tables stand out as a preferred option.

Cast iron, a metal alloy primarily composed of iron and carbon, has been a staple in engineering for centuries due to its remarkable properties. In the context of welding, a cast iron welding table offers several advantages that make it a preferred choice among professionals.

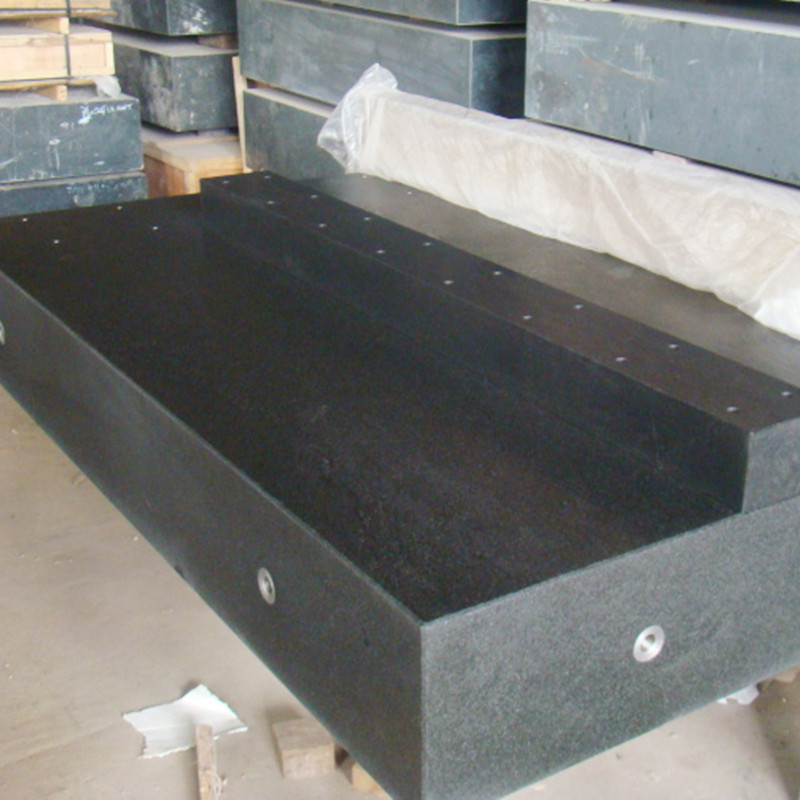

Firstly, cast iron's high thermal conductivity and heat retention capacity make it ideal for welding applications. It efficiently dissipates heat, minimizing distortion and warping, which is crucial in maintaining the accuracy and integrity of the workpiece. This characteristic is particularly beneficial during prolonged welding sessions or when working with materials that are sensitive to temperature changes.

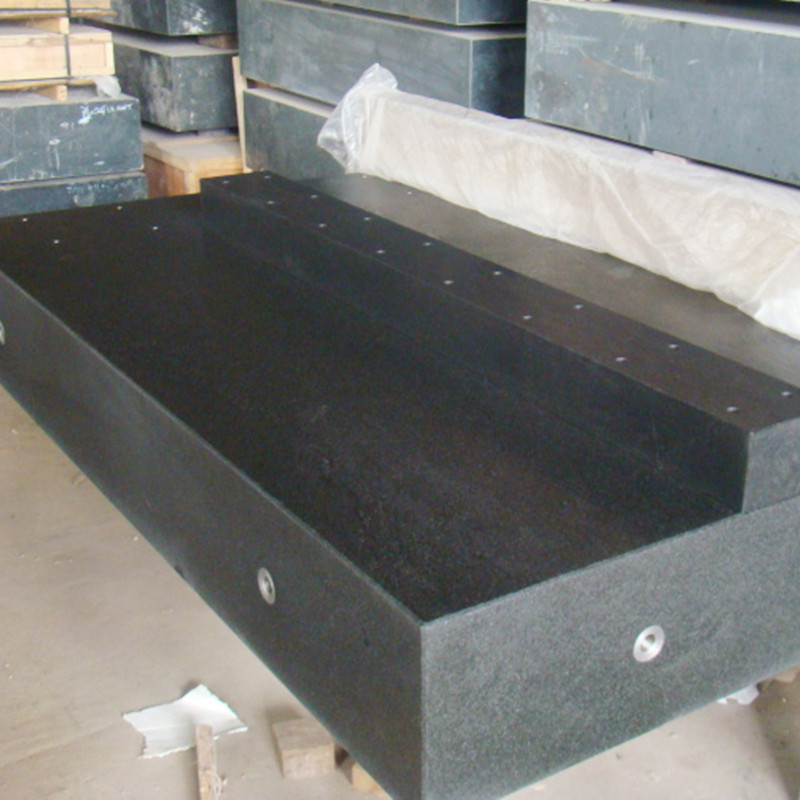

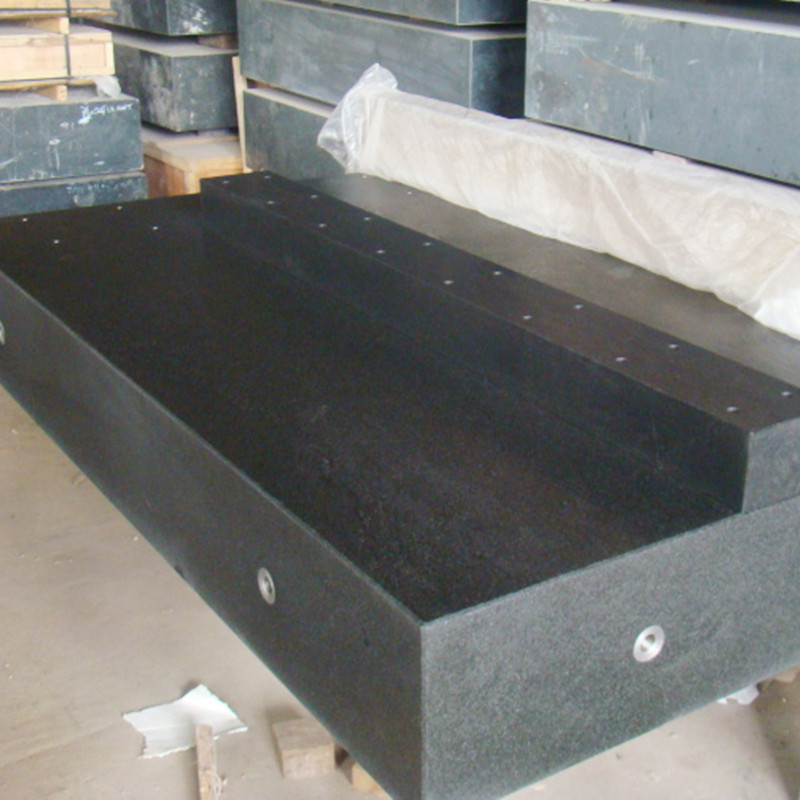

Secondly, the inherent strength and rigidity of cast iron contribute to the stability of the welding table. The sturdy construction ensures that the table remains steadfast even under heavy loads or during forceful welding operations. The robustness of cast iron also means that the table can withstand the wear and tear of frequent use, maintaining its functionality over time.

Moreover, the non-magnetic property of cast iron is another advantage. It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used

It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used welding table cast iron. Additionally, the smooth surface of a well-finished cast iron table allows for better clamping and holding of the workpieces, enhancing productivity and efficiency.

Furthermore, cast iron welding tables often come with a pre-drilled grid pattern, facilitating easy clamping and fixture setup. This feature not only saves time but also promotes consistency and accuracy in welding projects, making it easier to replicate welds and maintain quality standards.

However, it's worth noting that cast iron does have its drawbacks. It is heavier than other materials, which can limit portability. It's also susceptible to rust if not properly maintained, requiring regular cleaning and protective coatings.

In conclusion, a welding table made from cast iron offers a robust, stable, and accurate platform for welding operations. Its unique properties, such as high thermal conductivity, strength, and non-magnetic nature, make it an indispensable tool for professional welders and workshops. Despite a few limitations, the benefits of a cast iron welding table significantly outweigh the drawbacks, making it a worthwhile investment for those seeking reliability and precision in their welding processes.

welding table cast iron. Additionally, the smooth surface of a well-finished cast iron table allows for better clamping and holding of the workpieces, enhancing productivity and efficiency.

Furthermore, cast iron welding tables often come with a pre-drilled grid pattern, facilitating easy clamping and fixture setup. This feature not only saves time but also promotes consistency and accuracy in welding projects, making it easier to replicate welds and maintain quality standards.

However, it's worth noting that cast iron does have its drawbacks. It is heavier than other materials, which can limit portability. It's also susceptible to rust if not properly maintained, requiring regular cleaning and protective coatings.

In conclusion, a welding table made from cast iron offers a robust, stable, and accurate platform for welding operations. Its unique properties, such as high thermal conductivity, strength, and non-magnetic nature, make it an indispensable tool for professional welders and workshops. Despite a few limitations, the benefits of a cast iron welding table significantly outweigh the drawbacks, making it a worthwhile investment for those seeking reliability and precision in their welding processes.

It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used

It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used It eliminates magnetic interference, allowing for more precise welding, especially in applications where magnetic fixtures are used welding table cast iron. Additionally, the smooth surface of a well-finished cast iron table allows for better clamping and holding of the workpieces, enhancing productivity and efficiency.

Furthermore, cast iron welding tables often come with a pre-drilled grid pattern, facilitating easy clamping and fixture setup. This feature not only saves time but also promotes consistency and accuracy in welding projects, making it easier to replicate welds and maintain quality standards.

However, it's worth noting that cast iron does have its drawbacks. It is heavier than other materials, which can limit portability. It's also susceptible to rust if not properly maintained, requiring regular cleaning and protective coatings.

In conclusion, a welding table made from cast iron offers a robust, stable, and accurate platform for welding operations. Its unique properties, such as high thermal conductivity, strength, and non-magnetic nature, make it an indispensable tool for professional welders and workshops. Despite a few limitations, the benefits of a cast iron welding table significantly outweigh the drawbacks, making it a worthwhile investment for those seeking reliability and precision in their welding processes.

welding table cast iron. Additionally, the smooth surface of a well-finished cast iron table allows for better clamping and holding of the workpieces, enhancing productivity and efficiency.

Furthermore, cast iron welding tables often come with a pre-drilled grid pattern, facilitating easy clamping and fixture setup. This feature not only saves time but also promotes consistency and accuracy in welding projects, making it easier to replicate welds and maintain quality standards.

However, it's worth noting that cast iron does have its drawbacks. It is heavier than other materials, which can limit portability. It's also susceptible to rust if not properly maintained, requiring regular cleaning and protective coatings.

In conclusion, a welding table made from cast iron offers a robust, stable, and accurate platform for welding operations. Its unique properties, such as high thermal conductivity, strength, and non-magnetic nature, make it an indispensable tool for professional welders and workshops. Despite a few limitations, the benefits of a cast iron welding table significantly outweigh the drawbacks, making it a worthwhile investment for those seeking reliability and precision in their welding processes.

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS