Jul . 29, 2025 09:52 Back to list

Cast Iron Surface Plate Offers Superior Rigidity

In industrial manufacturing, precision, durability, and efficiency are the cornerstones of success. From measuring components to shaping metal and refining surfaces, specialized tools play a pivotal role in ensuring quality and reliability. Among these tools, cast iron surface plate, metal fabrication table, and cast iron lapping plate stand out for their unique designs tailored to specific industrial needs. These products combine robust construction with functional precision, making them indispensable in metrology, fabrication, and finishing processes. In this guide, we’ll explore their features, applications, and benefits, highlighting how they contribute to seamless operations in diverse industrial settings.

The Precision and Reliability of Cast Iron Surface Plate in Metrology

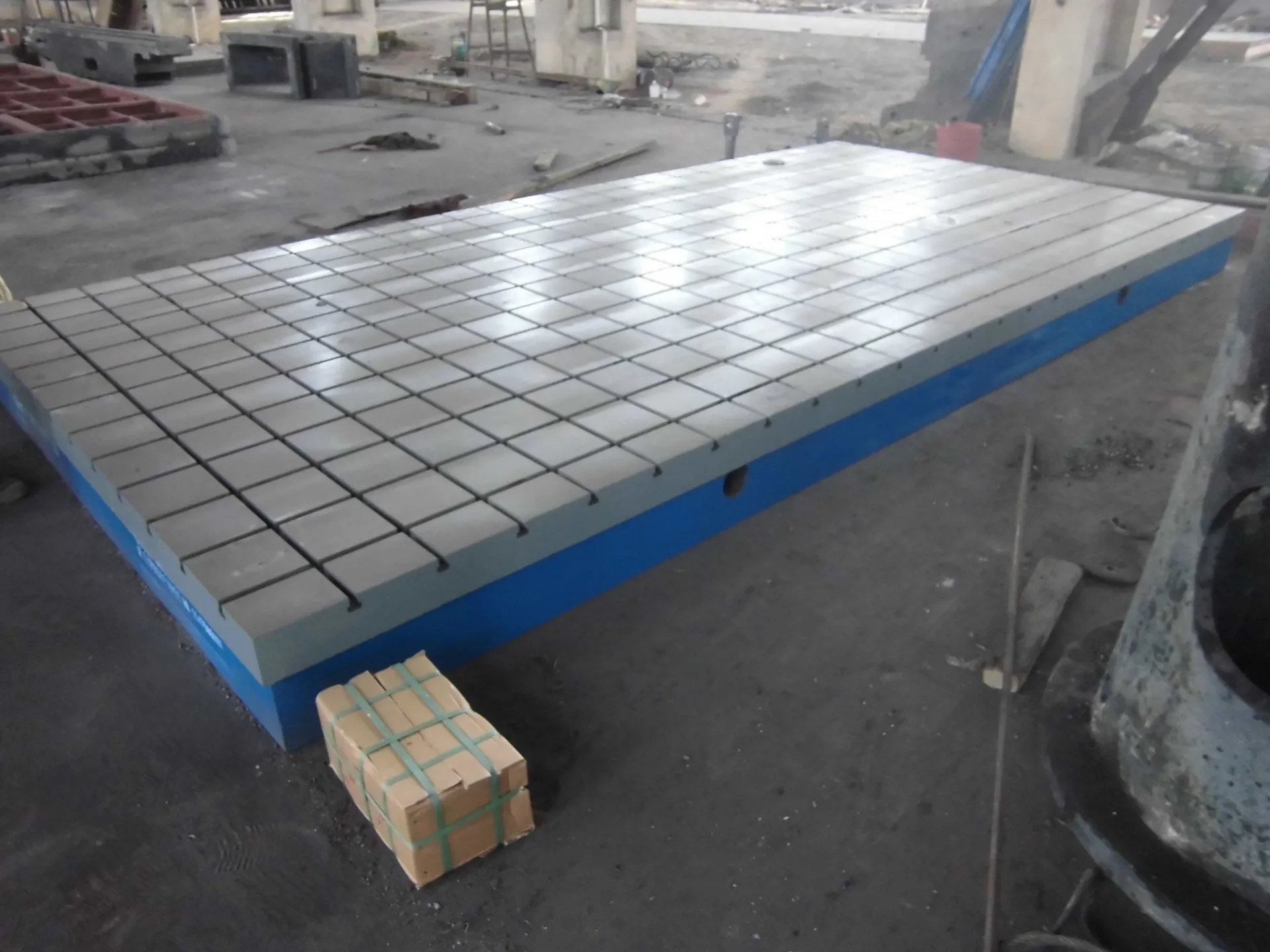

Cast iron surface plate is a foundational tool in metrology (the science of measurement), valued for its exceptional flatness, stability, and durability. Crafted from high-grade cast iron, these plates serve as a reference surface for calibrating instruments, inspecting component dimensions, and ensuring alignment in manufacturing processes.

At the core of a cast iron surface plate’s functionality is its ultra-flat surface, achieved through careful machining and aging processes. Cast iron’s inherent properties—including high density, vibration damping, and resistance to warping—make it ideal for maintaining precision over time. Unlike materials like steel or stone, cast iron minimizes thermal expansion, ensuring consistent flatness even in fluctuating temperatures. This stability is critical for tasks like checking part straightness, verifying parallelism, or calibrating measuring tools such as micrometers and dial indicators.

Cast iron surface plate is also designed for longevity. Its surface is often treated with a protective coating to resist corrosion and wear, while periodic reconditioning (via lapping or scraping) restores flatness after extended use. In industries like aerospace, automotive, and precision engineering, where measurements must meet strict tolerances, a cast iron surface plate is more than a tool—it’s a cornerstone of quality control, ensuring that every component meets exact specifications.

How Metal Fabrication Table Enhances Efficiency in Manufacturing Workflows

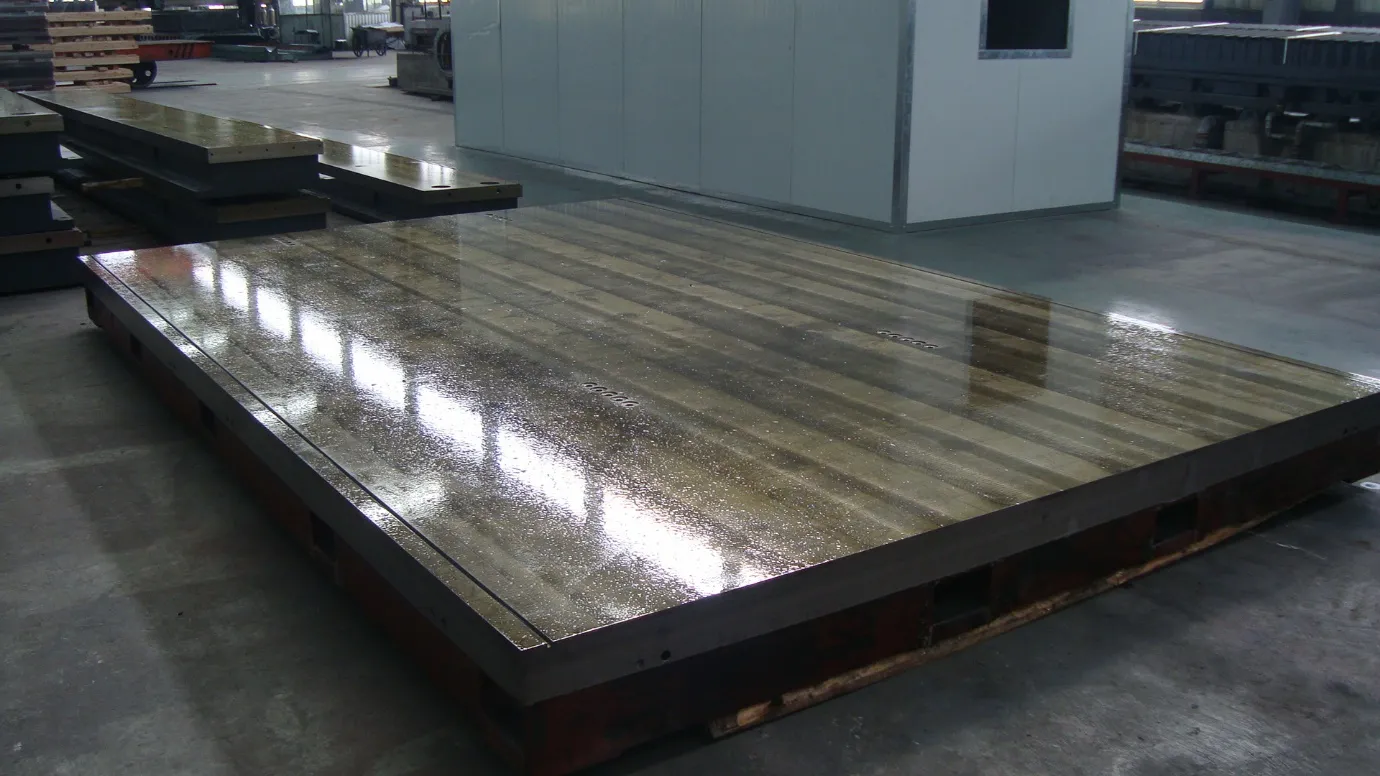

Metal fabrication table is the workhorse of manufacturing shops, providing a durable, versatile surface for cutting, welding, assembling, and finishing metal components. Unlike general-purpose workbenches, these tables are engineered to withstand the rigors of fabrication, including heavy loads, heat, and mechanical stress—making them essential for streamlining workflows.

The key advantage of a metal fabrication table is its robust construction, typically featuring a thick steel or cast iron top with reinforced framing. This design supports heavy materials like steel plates or structural beams without sagging, ensuring stability during precision tasks like welding or drilling. Many tables also include integrated features such as T-slots, holes, or edges for clamping work pieces securely, reducing setup time and minimizing movement during fabrication.

Metal fabrication table adapts to diverse needs, with options for different sizes, surface treatments (like anti-spatter coatings for welding), and accessories (such as tool rails or storage drawers). In small shops and large factories alike, it serves as a central hub for fabrication processes, from initial cutting to final assembly. Its durability ensures it withstands daily use, while its versatility reduces the need for multiple specialized work surfaces—ultimately enhancing efficiency and productivity in manufacturing workflows.

The Role of Cast Iron Lapping Plate in Achieving Ultra-Smooth Surfaces

Cast iron lapping plate is a specialized tool used in the lapping process, a precision finishing technique that creates ultra-smooth, flat surfaces on metal components. Lapping involves rubbing a workpiece against the plate’s surface, often with an abrasive compound, to remove tiny amounts of material and correct imperfections—resulting in surfaces with minimal roughness and tight flatness tolerances.

Cast iron lapping plate is uniquely suited for this task due to its material properties.** Cast iron’s porous structure holds abrasive compounds evenly, ensuring consistent material removal across the workpiece surface. Its hardness (typically hardened to 180–250 HB) resists wear, maintaining a uniform texture that produces predictable, repeatable results. Whether used for finishing engine parts, hydraulic components, or optical surfaces, the plate’s flatness directly influences the workpiece’s final quality—making it a critical tool for achieving mirror-like finishes or precise dimensional accuracy.

Cast iron lapping plate also offers flexibility. Plates come in various sizes and surface patterns (such as grooved or plain), allowing customization for specific workpieces. After use, they can be reconditioned by resurfacing to restore their abrasive-holding capacity, extending their lifespan. For industries where surface quality impacts performance (e.g., sealing, friction reduction), a cast iron lapping plate is indispensable, transforming rough components into precision parts.

Key Features Comparing Cast Iron Surface Plate, Metal Fabrication Table, and Cast Iron Lapping Plate

To understand how these tools differ and complement each other, consider their core features and applications:

|

Tool Type |

Primary Material |

Key Features |

Primary Applications |

|

Cast Iron Surface Plate |

High-Grade Cast Iron |

Ultra-flat surface, vibration damping, corrosion resistance, reconditionable. |

Metrology, calibration, part inspection, checking tolerances. |

|

Metal Fabrication Table |

Steel or Cast Iron |

Heavy load capacity, reinforced framing, clamping slots, heat resistance. |

Welding, cutting, assembly, finishing metal components. |

|

Cast Iron Lapping Plate |

Hardened Cast Iron |

Porous surface for abrasive retention, uniform hardness, reconditionable. |

Precision finishing, achieving ultra-smooth surfaces, correcting flatness. |

While each tool serves a distinct purpose, they share a focus on durability and functionality, ensuring reliability in demanding industrial environments. Their designs reflect their specific roles: precision for metrology, strength for fabrication, and finesse for surface finishing.

FAQS about Cast Iron Surface Plate, Metal Fabrication Table, and Cast Iron Lapping Plate

What makes cast iron surface plate the preferred choice for precision measurement?

Cast iron surface plate is preferred for precision measurement due to its exceptional flatness and stability. Cast iron’s low thermal expansion rate ensures the surface remains flat in temperature changes, while its vibration-damping properties reduce measurement errors. Its durability and ability to be reconditioned (via lapping or scraping) also ensure long-term accuracy, making it ideal for metrology tasks requiring strict tolerances.

How does a metal fabrication table withstand high heat from welding processes?

Metal fabrication table withstands high heat through its robust construction, typically featuring a thick steel or cast iron top that dissipates heat effectively. Many tables are also treated with heat-resistant coatings that prevent warping or damage from welding sparks. Reinforced framing adds structural integrity, ensuring the table remains stable even when exposed to repeated heat cycles during fabrication.

What is the role of abrasive compounds with a cast iron lapping plate?

Abrasive compounds work with cast iron lapping plate to remove tiny material particles from workpieces, creating smooth surfaces. The plate’s porous surface holds the abrasive evenly, ensuring consistent contact with the workpiece. As the workpiece is rubbed against the plate, the abrasive cuts into the surface, correcting imperfections and achieving the desired flatness or finish—making the compound a critical partner to the lapping plate.

Can a cast iron surface plate be used for both small and large component inspection?

Yes, cast iron surface plate is available in various sizes, from small benchtop models to large floor-mounted plates, making it suitable for inspecting both small and large components. Small plates work for precision parts like gears or bearings, while large plates accommodate structural components or assemblies. Their uniform flatness across the entire surface ensures accurate measurements regardless of component size.

What maintenance does a metal fabrication table require to stay functional long-term?

To keep a metal fabrication table functional, regular maintenance includes cleaning the surface to remove debris, welding spatter, or chemicals that could cause corrosion. Inspecting and tightening clamping hardware prevents loosening during use. For steel tops, applying a rust-resistant coating periodically protects against corrosion, while checking for structural damage (like cracks or warping) ensures safety and stability over time.

At [Storaen (Cangzhou) International Trading Co], we specialize in providing high-quality industrial tools, including cast iron surface plate, metal fabrication table, and cast iron lapping plate, designed to meet the demands of precision manufacturing and fabrication. Our products are crafted from premium materials, engineered for durability, and rigorously tested to ensure performance.

-

Thread Plug Gauge Requires Careful HandlingNewsJul.29,2025

-

Surface plate calibrationNewsJul.29,2025

-

Ring Gauge Ensures Machining AccuracyNewsJul.29,2025

-

Pad Iron Reinforces Anchor PointsNewsJul.29,2025

-

Ground anchor stabilizes embankmentsNewsJul.29,2025

-

Granite Box Maintains Precision FlatnessNewsJul.29,2025

Related PRODUCTS