Jul . 22, 2024 01:16 Back to list

Best Practices for Using Metal Pipe Saddle Clamps in Construction and Maintenance Projects

Understanding Metal Pipe Saddle Clamps Applications and Benefits

In various industrial and construction applications, metal pipe saddle clamps play a crucial role in securing and supporting pipe systems. These clamps are designed to hold pipes in place, ensuring stability and alignment, which are essential for the safe and efficient operation of piping systems. This article delves into the characteristics, applications, and benefits of metal pipe saddle clamps.

What are Metal Pipe Saddle Clamps?

Metal pipe saddle clamps are fasteners that consist of a curved base, typically referred to as the saddle, that matches the shape of the pipe it is supporting. The saddle is complemented by a closure mechanism, usually a bolt or screw, that secures the pipe in place. Made from durable materials such as stainless steel, carbon steel, or aluminum, these clamps are engineered to withstand environmental stresses and corrosion, making them suitable for various applications.

Applications of Metal Pipe Saddle Clamps

Metal pipe saddle clamps are versatile and can be found in numerous industries, including

1. Construction In building projects, these clamps are essential for securing plumbing and HVAC systems. They help maintain precise alignment during installation and ensure that piping systems operate efficiently over time.

2. Manufacturing Factories often employ these clamps to fix pipes carrying fluids, gases, and chemicals. Metal clamps provide the necessary support for heavy pipelines and aid in the smooth operation of production processes.

3. Oil and Gas Industries In this sector, the integrity of piping systems is paramount. Metal pipe saddle clamps provide secure attachments to pipelines, preventing leaks and ensuring safe transportation of hazardous materials.

4. Agriculture In agricultural applications, these clamps can be used to support irrigation systems and chemical distribution lines, ensuring that water and fertilizers are delivered effectively and reliably.

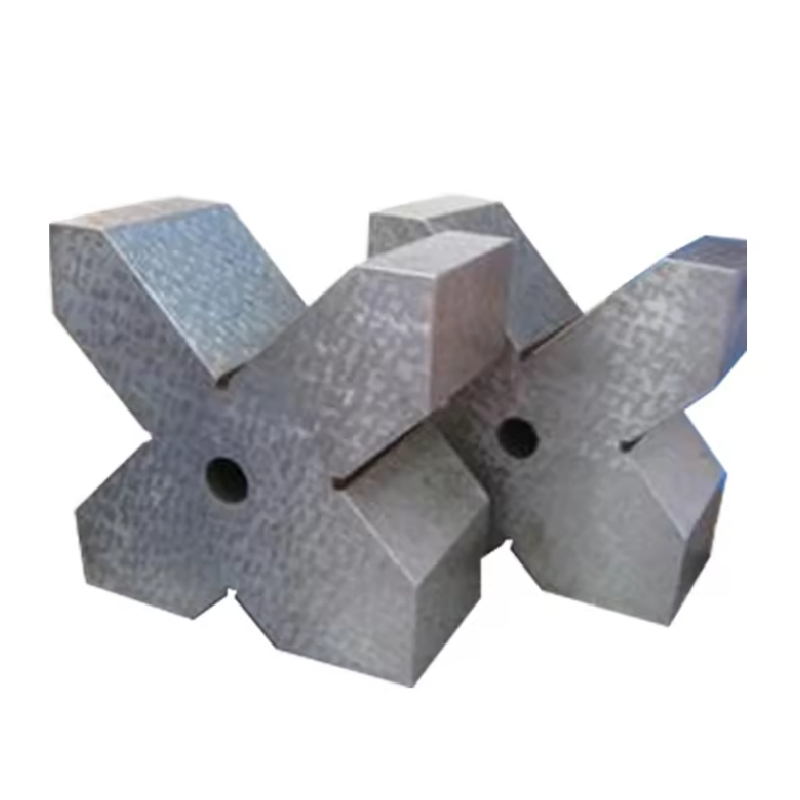

metal pipe saddle clamps

5. Marine Applications Metal pipe saddle clamps are used within ships and offshore platforms to secure pipelines in a harsh and corrosive environment. Their robust construction ensures long-lasting performance even in extreme conditions.

Benefits of Using Metal Pipe Saddle Clamps

The use of metal pipe saddle clamps comes with several notable benefits

1. Durability Constructed from high-strength materials, metal clamps provide long-lasting stability and support. They can resist wear, corrosion, and extreme temperatures, resulting in lower replacement costs over time.

2. Ease of Installation Metal pipe saddle clamps are designed for easy installation and adjustment. Whether using a minimal toolkit or performing intricate assembly, these clamps simplify the process of securing pipes.

3. Versatility These clamps come in various sizes and designs, allowing them to accommodate different pipe diameters and materials. This adaptability makes them suitable for diverse applications across various sectors.

4. Safety Assurance By securely holding pipes in place, metal saddle clamps help prevent accidents caused by pipe shifting or leaking. In industries where safety is critical, having reliable clamps is essential for minimizing risks.

5. Cost-Effectiveness Investing in metal pipe saddle clamps can lead to significant cost savings. Their durability and reliability reduce the frequency of maintenance and replacement, leading to lower operational expenses in the long term.

Conclusion

In conclusion, metal pipe saddle clamps serve as vital components in numerous industries, providing essential support and stability for piping systems. Their robust construction, ease of installation, and versatility make them a practical choice for ensuring the safety and efficiency of fluid and gas transportation. As industries continue to evolve, the reliance on these clamps will only increase, reinforcing their importance in modern engineering and construction practices. Whether in a factory, building site, or offshore platform, metal pipe saddle clamps are a small yet indispensable part of the larger operational framework.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNewsAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNewsAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNewsAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNewsAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNewsAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNewsAug.20,2025

Related PRODUCTS