Feb . 15, 2025 07:47 Back to list

Ball Check Valve

The ball bearing check valve stands as a pivotal component in fluid control systems across a range of industries. Renowned for its efficiency and reliability, its application can be seen from automotive systems to industrial machinery. As someone who has extensively worked with these devices, I can assertively discuss the invaluable role they play in ensuring system integrity and operational efficiency.

In practical application, ball bearing check valves are particularly prominent in hydraulic systems, ensuring the integrity of fluid dynamics crucial for machine operations. They serve as a safeguard against backpressure which could otherwise lead to equipment failure. I've seen firsthand the consequences of neglecting proper valve maintenance in industrial settings - costly repairs and extended downtime. Therefore, ensuring the integration of reliable check valves like the ball bearing type becomes essential. Furthermore, their role in energy efficiency should not be understated. By preventing backflow, these valves aid in maintaining system pressure and reducing energy consumption, aligning with global demands for sustainable industrial practices. This efficiency often translates to significant cost savings over the lifecycle of the equipment, providing a compelling case for incorporating high-quality ball bearing check valves into system designs. For professionals and technicians seeking to optimize system performance, selecting a suitable ball bearing check valve demands careful consideration of several factors, including valve size, material compatibility, pressure ratings, and temperature tolerance. Engaging with manufacturers that offer bespoke solutions can provide an added advantage, tailoring valve specifications to meet precise operational demands. In conclusion, the ball bearing check valve exemplifies superior engineering that combines functionality, reliability, and efficiency. Its ubiquitous presence across diverse sectors stands as a testament to its indispensable functionality. Specialists in fluid systems would do well to prioritize its integration to enhance operational outcomes. As industries advance towards more complex systems, the demand for reliable components like the ball bearing check valve is set to rise, continuing to uphold industrial standards of safety and efficiency.

In practical application, ball bearing check valves are particularly prominent in hydraulic systems, ensuring the integrity of fluid dynamics crucial for machine operations. They serve as a safeguard against backpressure which could otherwise lead to equipment failure. I've seen firsthand the consequences of neglecting proper valve maintenance in industrial settings - costly repairs and extended downtime. Therefore, ensuring the integration of reliable check valves like the ball bearing type becomes essential. Furthermore, their role in energy efficiency should not be understated. By preventing backflow, these valves aid in maintaining system pressure and reducing energy consumption, aligning with global demands for sustainable industrial practices. This efficiency often translates to significant cost savings over the lifecycle of the equipment, providing a compelling case for incorporating high-quality ball bearing check valves into system designs. For professionals and technicians seeking to optimize system performance, selecting a suitable ball bearing check valve demands careful consideration of several factors, including valve size, material compatibility, pressure ratings, and temperature tolerance. Engaging with manufacturers that offer bespoke solutions can provide an added advantage, tailoring valve specifications to meet precise operational demands. In conclusion, the ball bearing check valve exemplifies superior engineering that combines functionality, reliability, and efficiency. Its ubiquitous presence across diverse sectors stands as a testament to its indispensable functionality. Specialists in fluid systems would do well to prioritize its integration to enhance operational outcomes. As industries advance towards more complex systems, the demand for reliable components like the ball bearing check valve is set to rise, continuing to uphold industrial standards of safety and efficiency.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

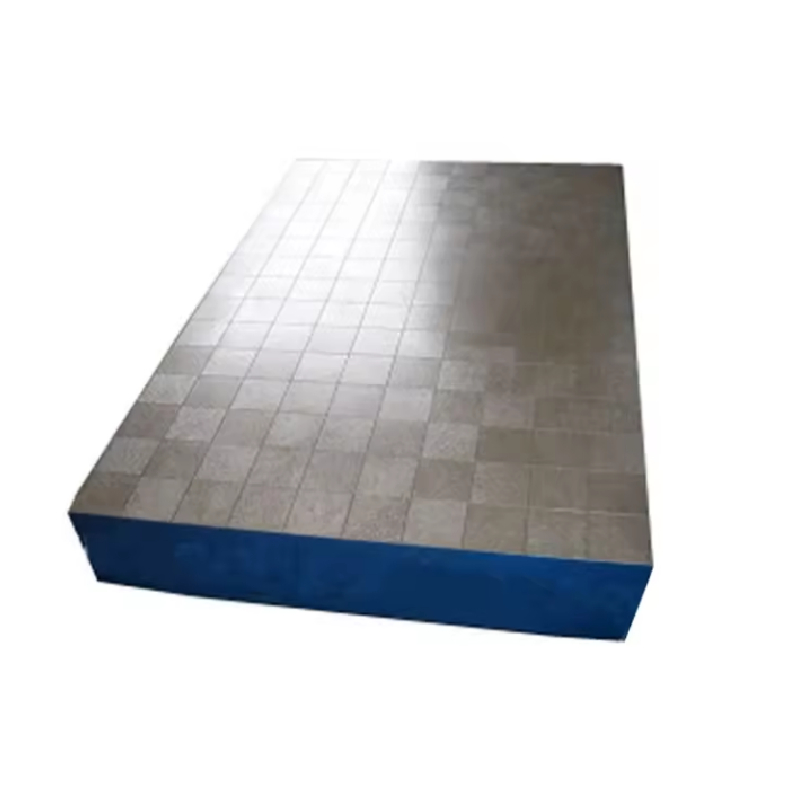

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS