Jul . 29, 2024 23:41 Back to list

Affordable Pricing Options for Globe Valves and Their Market Trends Today

Understanding Globe Valve Prices Factors and Insights

When it comes to industrial processes, the importance of valves cannot be overstated. Among the various types of valves used, globe valves play a pivotal role in regulating fluid flow in pipelines. They are designed to perform well in both throttling and on-off services, making them a preferred choice in many applications. This article aims to dissect the factors influencing globe valve prices, providing insights for potential buyers and industry professionals.

What is a Globe Valve?

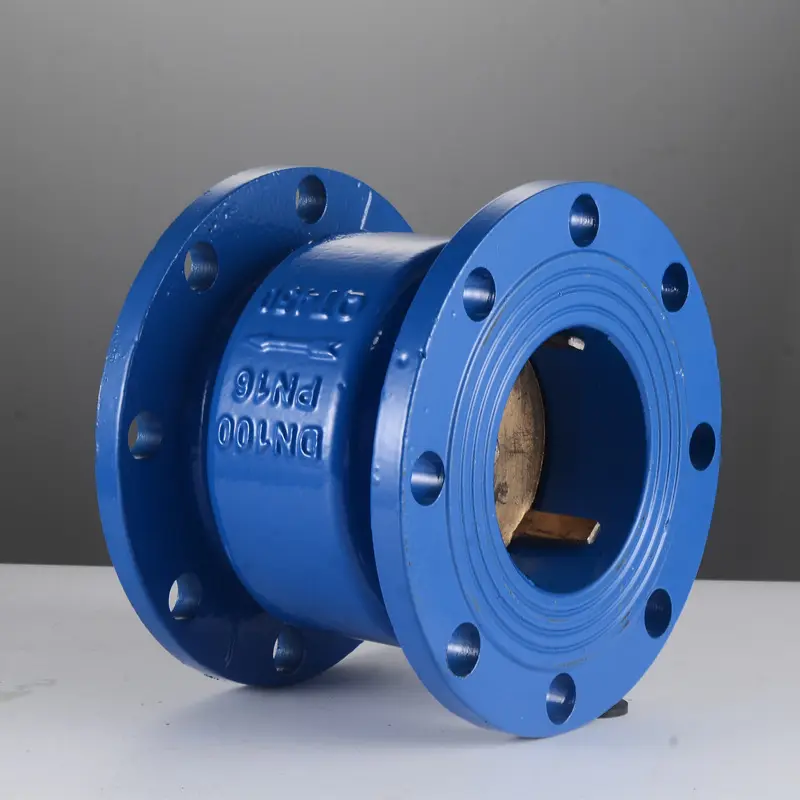

A globe valve is characterized by its spherical body shape, which allows for a more controlled flow of fluid. The design permits a significant amount of throttling capability, thus enabling it to adjust the flow rate of fluids with precision. Commonly found in steam, water, oil, and gas applications, globe valves are integral to maintaining safe and efficient operations in various industries including oil and gas, water treatment, and HVAC systems.

Factors Influencing Globe Valve Prices

1. Material Composition One of the most significant factors affecting the price of a globe valve is the material from which it is made. Globe valves can be constructed from a variety of materials such as brass, stainless steel, cast iron, and plastic. Stainless steel variants are generally more expensive due to their durability and resistance to corrosion, making them suitable for harsh environments.

2. Size and Design The size of the globe valve directly correlates with its price. Larger valves require more material and often entail more complex manufacturing processes. Additionally, specialized designs or custom specifications can further elevate costs, especially if they need to adhere to specific industry standards or safety regulations.

globe valve price

3. Pressure Rating Globe valves are rated for different pressure classes, which dictate their capability to withstand pressure without failure. Higher-rated valves are designed for high-pressure applications and can be considerably more expensive due to the engineering and materials required to ensure safety and reliability under such conditions.

4. Brand and Manufacturer The brand reputation and the manufacturer’s expertise can also play a role in pricing. Established companies with a long-standing history of reliability and quality will often charge a premium over lesser-known brands. Buyers must balance cost against the assurance of quality and performance.

5. Market Demand and Supply As with any commodity, market dynamics play a crucial role in pricing. In times of increased demand, such as during major infrastructure projects or resource shortages, prices can skyrocket. Conversely, during periods of lower demand or surplus, prices may decrease, providing an opportunity for cost-effective purchasing.

6. Additional Features Many globe valves come with additional features such as automated controls, which can boost their functionality but also increase costs. Integrated technologies that enhance operational efficiency often come at a higher price point, but their long-term benefits can justify the investment.

Conclusion

In summary, globe valve prices are influenced by a multitude of factors, ranging from material and size to brand reputation and current market conditions. For buyers, understanding these aspects is crucial in making informed purchasing decisions. While it can be tempting to opt for the lowest-priced option, considering the long-term implications of quality, durability, and performance is essential. Ultimately, investing in a high-quality globe valve can lead to reduced maintenance costs and increased operational efficiency in the long run, making it a wise financial decision for any industry.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS