Jun . 13, 2024 11:47 Back to list

8 Knife Gate Valve can be approximated in a shorter sentence as A sharp-edged valve for controlling fluid flow.

Understanding the 8 Knife Gate Valve A Comprehensive Overview

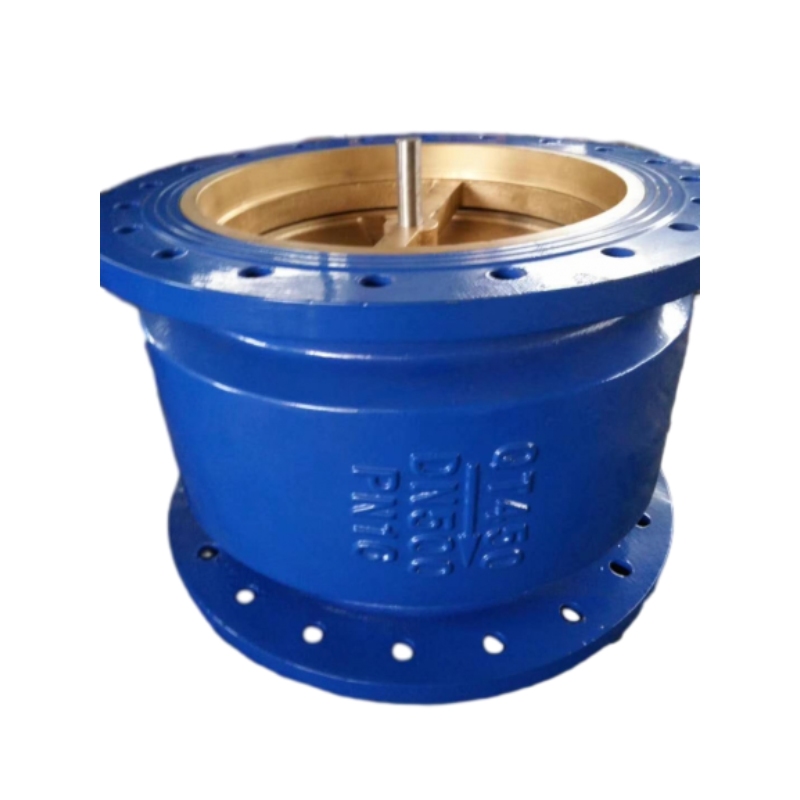

In the world of industrial fluid control systems,,。,8 Knife Gate Valve is a specialized type that finds its niche in handling slurries and other abrasive materials. This article aims to delve into the intricacies of this particular valve, elucidating its design, function, and advantages.

A Knife Gate Valve, also known as a slurry valve, is designed primarily for on/off services where a sharp, knife-like edge is needed to cut through suspended solids in the media. The 8 in the term refers to the valve's unique design feature, which incorporates an 8-degree bevel on the blade edge. This bevel serves as a slicing mechanism, effectively separating and clearing solid particles from the flow path when the valve is closed.

The body of an 8 Knife Gate Valve is typically made from robust materials like stainless steel or cast iron, ensuring durability and resistance against corrosion. The gate, the key component, is fashioned with a sharp edge that can slice through fibrous or stringy substances without getting caught. The valve's simplicity in design—consisting of a single moving part—minimizes maintenance needs and potential points of failure.

Functionally, the 8 Knife Gate Valve operates linearly. When the valve handle is turned, it lifts the gate, allowing the fluid to flow through the open passage. Conversely, when the handle is turned in the opposite direction, the gate descends, sealing against the seat with the assistance of the 8-degree bevel, thus stopping the flow. This straightforward operation makes it ideal for applications where rapid shut-off is necessary This straightforward operation makes it ideal for applications where rapid shut-off is necessary This straightforward operation makes it ideal for applications where rapid shut-off is necessary This straightforward operation makes it ideal for applications where rapid shut-off is necessary

This straightforward operation makes it ideal for applications where rapid shut-off is necessary This straightforward operation makes it ideal for applications where rapid shut-off is necessary 8 knife gate valve.

One of the primary advantages of the 8 Knife Gate Valve is its ability to handle high viscosity fluids and slurries containing solids. Its sharp-edged gate ensures minimal particle entrapment, reducing the risk of blockages and improving flow efficiency. Furthermore, its compact design allows for easy installation in tight spaces, while the lack of internal pockets or pockets reduces the likelihood of material buildup.

Despite these benefits, it's important to note that the 8 Knife Gate Valve is not designed for throttling purposes. Continuous partial closure could lead to wearing of the valve seat and gate edge, compromising the seal and potentially causing leakage. Therefore, it's crucial to use it correctly in on/off scenarios.

In conclusion, the 8 Knife Gate Valve is a highly specialized tool in the industrial pipeline, tailored for managing abrasive and fibrous materials. Its robust construction, efficient cutting mechanism, and straightforward operation make it an indispensable component in various industries, including mining, wastewater treatment, and pulp and paper processing. By understanding its functionality and limitations, engineers can optimize its usage and ensure smooth, uninterrupted flow control.

8 knife gate valve.

One of the primary advantages of the 8 Knife Gate Valve is its ability to handle high viscosity fluids and slurries containing solids. Its sharp-edged gate ensures minimal particle entrapment, reducing the risk of blockages and improving flow efficiency. Furthermore, its compact design allows for easy installation in tight spaces, while the lack of internal pockets or pockets reduces the likelihood of material buildup.

Despite these benefits, it's important to note that the 8 Knife Gate Valve is not designed for throttling purposes. Continuous partial closure could lead to wearing of the valve seat and gate edge, compromising the seal and potentially causing leakage. Therefore, it's crucial to use it correctly in on/off scenarios.

In conclusion, the 8 Knife Gate Valve is a highly specialized tool in the industrial pipeline, tailored for managing abrasive and fibrous materials. Its robust construction, efficient cutting mechanism, and straightforward operation make it an indispensable component in various industries, including mining, wastewater treatment, and pulp and paper processing. By understanding its functionality and limitations, engineers can optimize its usage and ensure smooth, uninterrupted flow control.

This straightforward operation makes it ideal for applications where rapid shut-off is necessary This straightforward operation makes it ideal for applications where rapid shut-off is necessary

This straightforward operation makes it ideal for applications where rapid shut-off is necessary This straightforward operation makes it ideal for applications where rapid shut-off is necessary 8 knife gate valve.

One of the primary advantages of the 8 Knife Gate Valve is its ability to handle high viscosity fluids and slurries containing solids. Its sharp-edged gate ensures minimal particle entrapment, reducing the risk of blockages and improving flow efficiency. Furthermore, its compact design allows for easy installation in tight spaces, while the lack of internal pockets or pockets reduces the likelihood of material buildup.

Despite these benefits, it's important to note that the 8 Knife Gate Valve is not designed for throttling purposes. Continuous partial closure could lead to wearing of the valve seat and gate edge, compromising the seal and potentially causing leakage. Therefore, it's crucial to use it correctly in on/off scenarios.

In conclusion, the 8 Knife Gate Valve is a highly specialized tool in the industrial pipeline, tailored for managing abrasive and fibrous materials. Its robust construction, efficient cutting mechanism, and straightforward operation make it an indispensable component in various industries, including mining, wastewater treatment, and pulp and paper processing. By understanding its functionality and limitations, engineers can optimize its usage and ensure smooth, uninterrupted flow control.

8 knife gate valve.

One of the primary advantages of the 8 Knife Gate Valve is its ability to handle high viscosity fluids and slurries containing solids. Its sharp-edged gate ensures minimal particle entrapment, reducing the risk of blockages and improving flow efficiency. Furthermore, its compact design allows for easy installation in tight spaces, while the lack of internal pockets or pockets reduces the likelihood of material buildup.

Despite these benefits, it's important to note that the 8 Knife Gate Valve is not designed for throttling purposes. Continuous partial closure could lead to wearing of the valve seat and gate edge, compromising the seal and potentially causing leakage. Therefore, it's crucial to use it correctly in on/off scenarios.

In conclusion, the 8 Knife Gate Valve is a highly specialized tool in the industrial pipeline, tailored for managing abrasive and fibrous materials. Its robust construction, efficient cutting mechanism, and straightforward operation make it an indispensable component in various industries, including mining, wastewater treatment, and pulp and paper processing. By understanding its functionality and limitations, engineers can optimize its usage and ensure smooth, uninterrupted flow control.

Latest news

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS