Aug . 17, 2024 14:34 Back to list

75mm butterfly valve specifications and application guide for effective flow control

The Importance of 75mm Butterfly Valves in Modern Industries

Butterfly valves play a crucial role in various industrial applications due to their simplistic design and efficient performance. Among various sizes and types, the 75mm butterfly valve stands out as a fiercely competitive component for flow regulation in piping systems. This article will delve into the significance of 75mm butterfly valves, outlining their structure, functional benefits, and their applications in modern industries.

Understanding Butterfly Valves

Butterfly valves are named for their disc-shaped closure mechanism that resembles the wings of a butterfly. These valves are particularly effective for regulating flow because they can be opened or closed quickly and with minimal resistance. The 75mm size indicates the diameter of the valve's opening, which makes it ideal for a variety of medium-scale applications where space and efficiency are paramount.

Structure and Operation

A typical 75mm butterfly valve consists of a circular body with a disc (the butterfly) mounted on a shaft. The valve operates through a quarter-turn motion. When the disc is perpendicular to the flow, the valve remains closed; when turned parallel to the flow, the valve opens, allowing the medium to pass through freely. This simple operation ensures rapid activation, facilitating efficient flow control and making it a preferred choice for many engineers.

Advantages of 75mm Butterfly Valves

1. Space Efficiency Due to their compact design, 75mm butterfly valves require less space compared to other valve types such as gate or ball valves. This makes them suitable for installations in tighter spaces, including pipelines and machinery compartments.

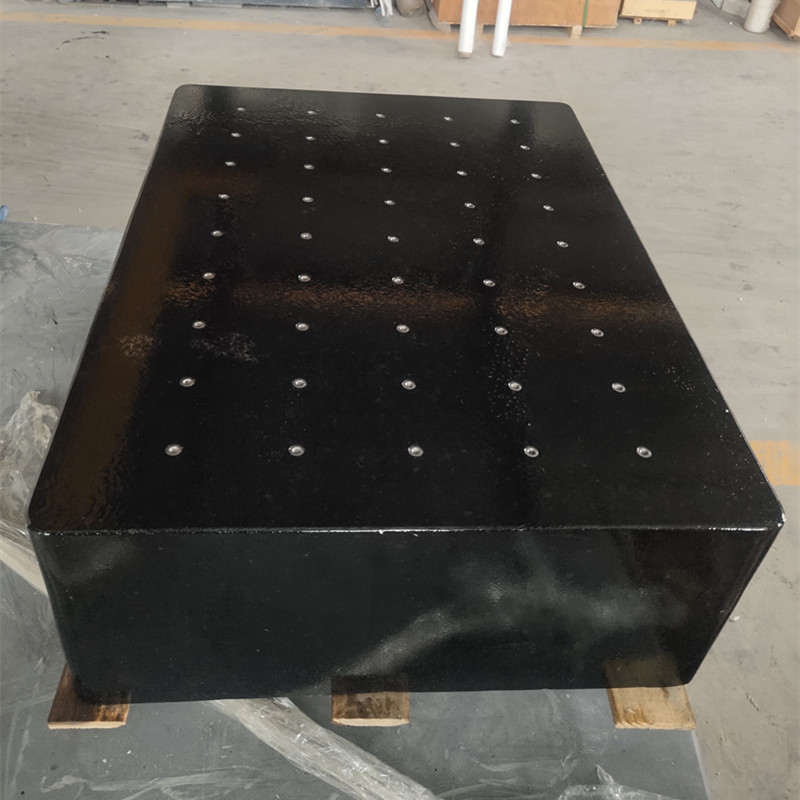

75mm butterfly valve

2. Low Pressure Drop Butterfly valves provide a minimal pressure drop across the valve when open. This characteristic enhances the efficiency of fluid transport by reducing energy costs associated with pumping and flow management.

3. Ease of Maintenance Maintenance is considerably easier with butterfly valves compared to other valve types. Their design allows for easy disassembly and cleaning, which ensures long-lasting performance with fewer interruptions in operations.

4. Versatile Applications The versatility of 75mm butterfly valves enables them to be used with various media, including water, gas, and oil. This adaptability is beneficial in sectors like water treatment, HVAC systems, chemical processing, and food and beverage manufacturing.

5. Cost-Effectiveness The manufacturing process of butterfly valves is generally more straightforward and less expensive than that of comparable valves. This results in lower purchasing costs and makes the 75mm butterfly valve an economic choice for many industries.

Applications Across Industries

The implementation of 75mm butterfly valves spans several sectors. In water treatment plants, they regulate the flow of water at various points in the system, ensuring it is treated effectively before distribution. In the HVAC industry, butterfly valves are utilized to control airflow in ducts, contributing to efficient heating and cooling systems. In manufacturing and processing plants, they play a crucial role in the handling of liquids and gases, providing the necessary control for process optimization.

Conclusion

The 75mm butterfly valve is a remarkable feat of engineering, offering an ideal mixture of efficiency, compactness, and versatility that meets the demands of modern industry. With its quick operation, maintenance-friendly design, and adaptability to various mediums, this valve has become an essential component in numerous applications. As industries continue to evolve and grow, the significance of reliable flow control solutions like the 75mm butterfly valve will undoubtedly remain paramount, ensuring safe and efficient operational processes across the globe. Proper selection and maintenance of these valves will contribute not only to operational efficiency but also to environmental sustainability in various industrial sectors.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS